A pressing reciprocating valve

A reciprocating valve technology, applied in multi-way valves, valve devices, engine components, etc., can solve the problems of single valve, can not achieve multi-directional flow, can not meet the diversification of valves, etc., to avoid damage, convenient control, Well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

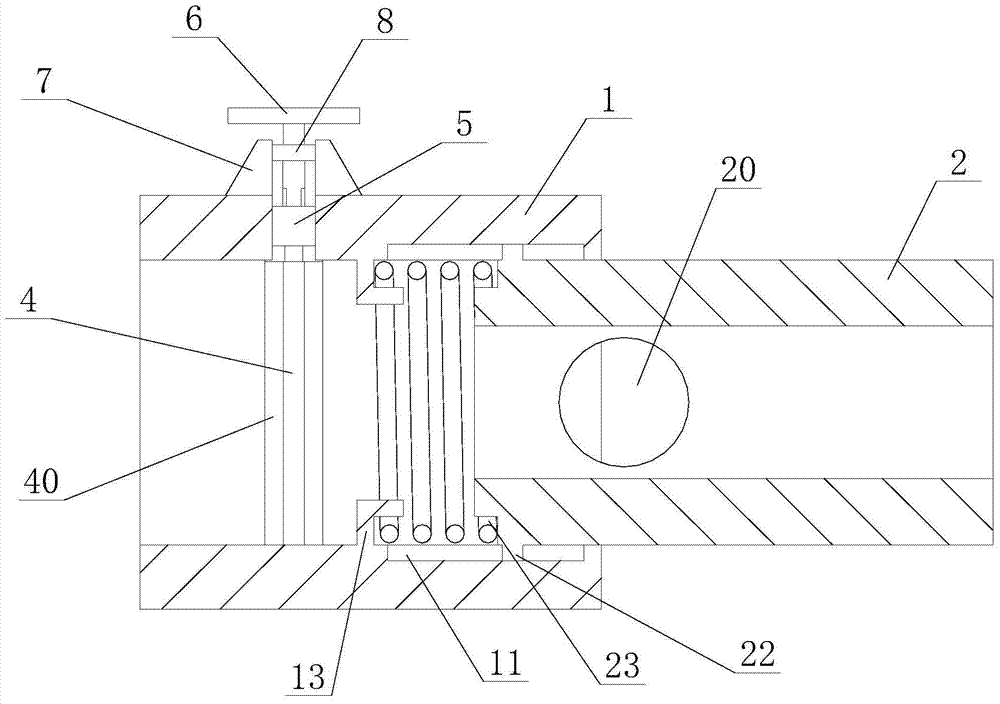

[0024] Such as figure 1 The push-and-press reciprocating valve shown includes a first pipeline 1, a second pipeline 2 and a third pipeline whose pipe diameters successively decrease and are socketed. The first pipeline 1 is provided with a central rod 4 and a valve flap 40, and the center The rod 4 runs through the first pipeline 1, and the central rod 4 located on the outer wall of the first pipeline 1 is connected to the handle 6. The rotation of the handle 6 drives the central rod 4 and the valve disc 40 to open and close, thereby controlling the on-off of the fluid in the first pipeline 1 and flow rate. The fixing block 5 is used to maintain the position of the central rod 4 , and the seal 8 is used to improve the sealing between the first pipe 1 and the central rod 4 .

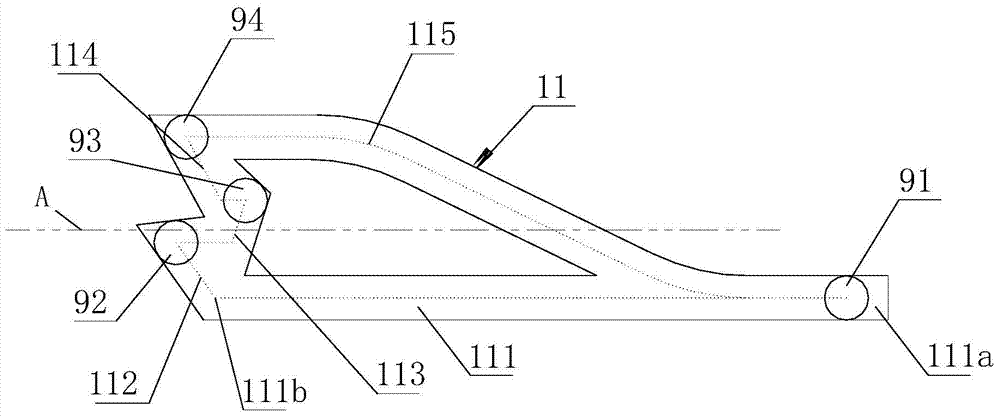

[0025] The first pipe 1 is slidingly socketed into the second pipe 2, and the elastic stretc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com