Filling device applied to liquefied natural gas (LNG) bottle

The technology of a filling device and a liquid filling device is applied in the field of LNG, which can solve the problems of decreased sealing performance, loose sealing cover, low sealing performance of the filling device, etc., so as to reduce the probability of loosening and improve the sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

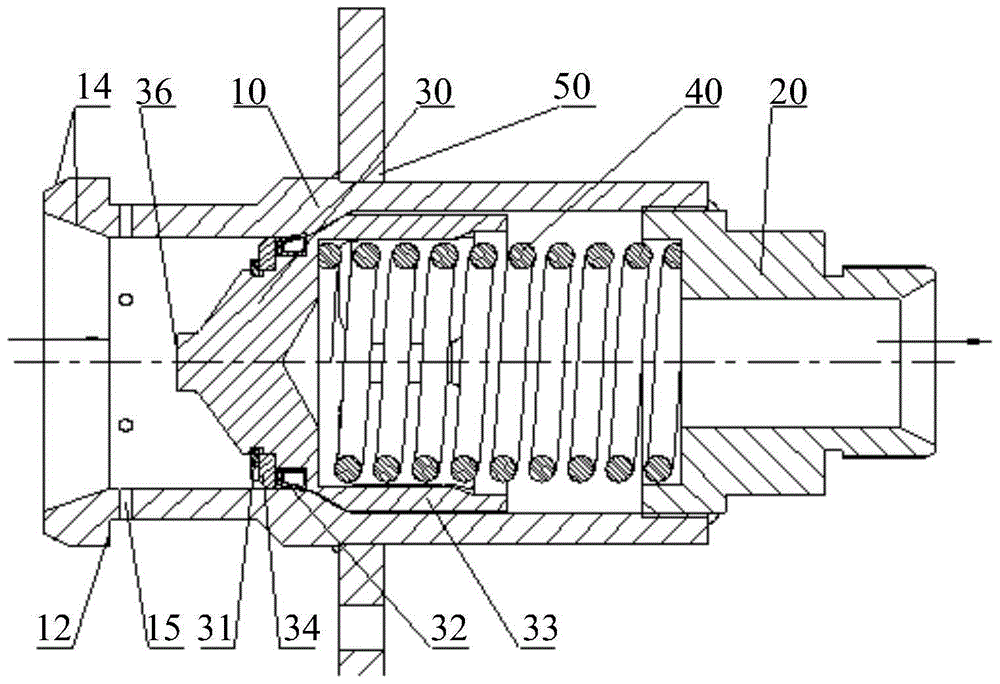

[0028] The invention provides a filling device applied to LNG bottles, which can improve the sealing performance of the filling device.

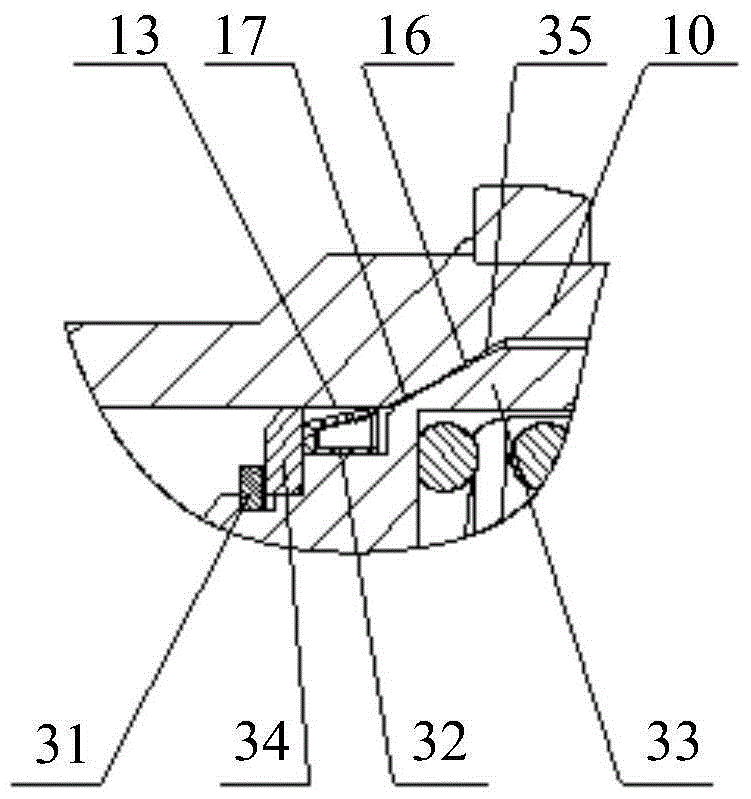

[0029] Embodiments of the present application Embodiments of the present application provide a filling device applied to LNG bottles, see figure 1 , the filling device includes: a housing 10 including a housing inlet 11 and a sealing surface 13, the housing inlet 11 is arranged at the front end of the housing 10, and the sealing surface 13 is arranged inside the housing 10; the outlet interface 20 is provided At the end of the housing 10, the outlet interface 20 matches the inlet of the LNG bottle; the valve core assembly 30 includes a clamp 31, a seal 32 and a valve core 33, wherein the clamp 31 is arranged at the front end inside the housing 10 , the sealing member 32 and the valve core 33 are arranged in the clamp 31, the sealing member 32 matches the sealing surface 13, and is used to realize sealing; the elastic member 40 is arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com