Involute gear shaping grinding wheel calculating method

A technology for involute gears and forming grinding wheels, which is applied to instruments, adaptive control, simulators, etc., can solve problems such as large subjective factors, unclear adjustment direction of modification parameters, and difficult control of shape and position parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

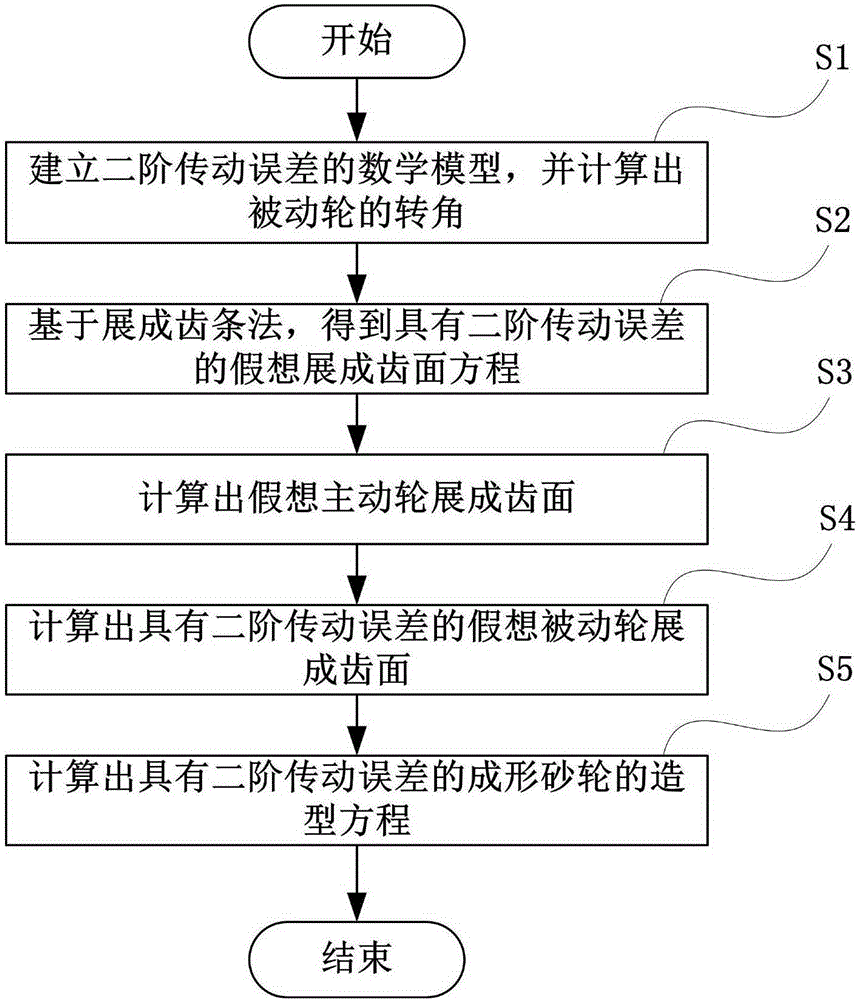

[0029] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments will specifically illustrate the calculation method of the involute gear forming grinding wheel of the present invention in conjunction with the accompanying drawings.

[0030] In this embodiment, the calculation method 100 for the involute gear forming grinding wheel is used to calculate the driving wheel and the driven wheel according to the preset second-order transmission error between the driving wheel and the driven wheel not shown in the figure. The modeling equation of a profiled grinding wheel for grinding tooth profiles.

[0031] figure 1 It is an action flow chart of the calculation method for the involute gear forming grinding wheel in the embodiment of the present invention.

[0032] like figure 1 As shown, the calculation method of involute gear forming grinding wheel includes the following steps:

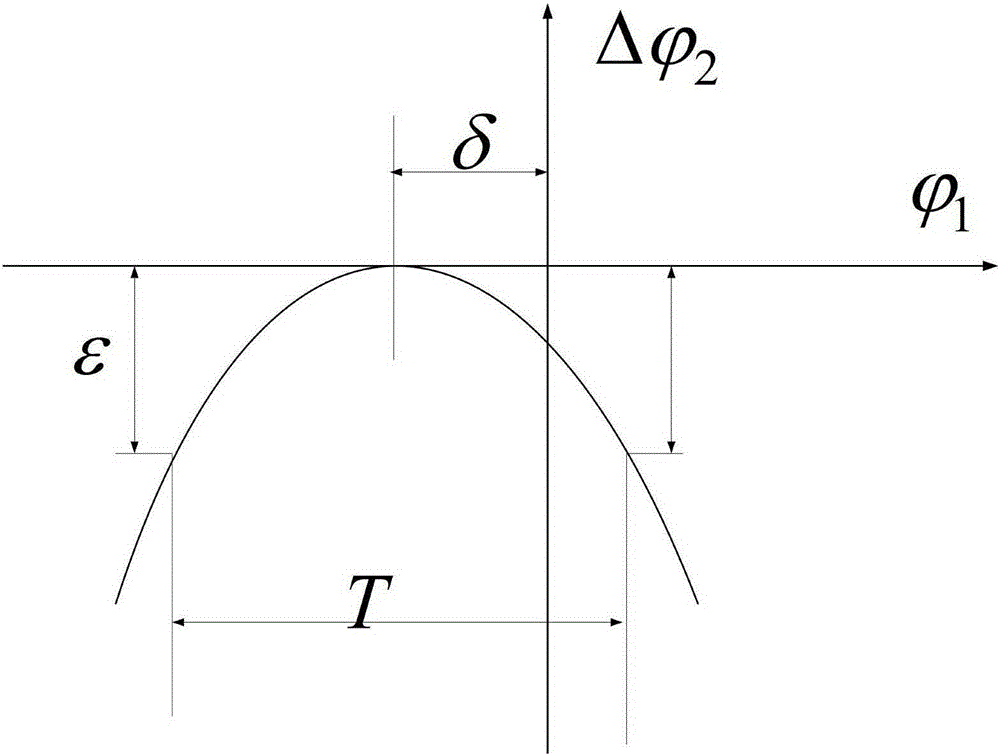

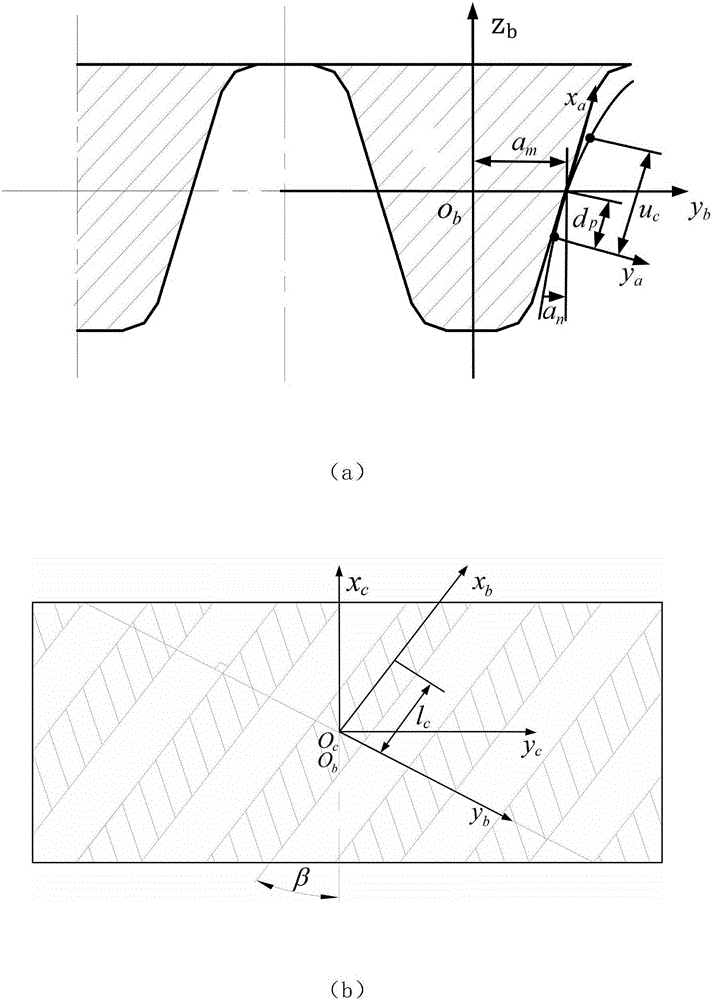

[0033] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com