Tool for rapidly fixing grout sleeve and using method of tool

A grouting sleeve and rapid technology, applied in the processing of building materials, structural elements, building components, etc., can solve the problems of complex operation and inconvenient operation, and achieve the effect of precise and efficient positioning, simple structure and coherent operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

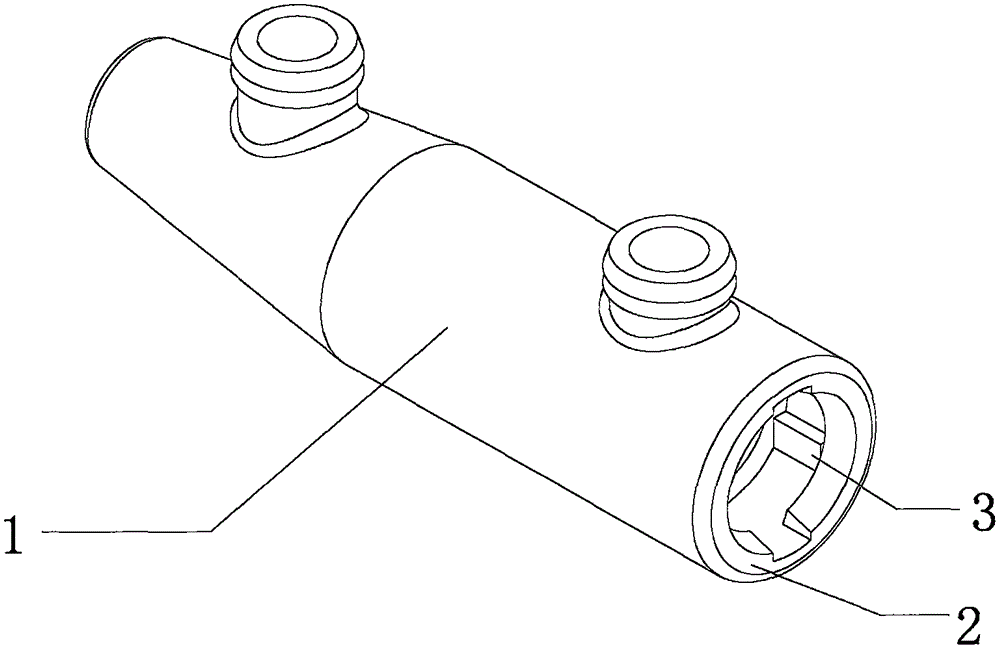

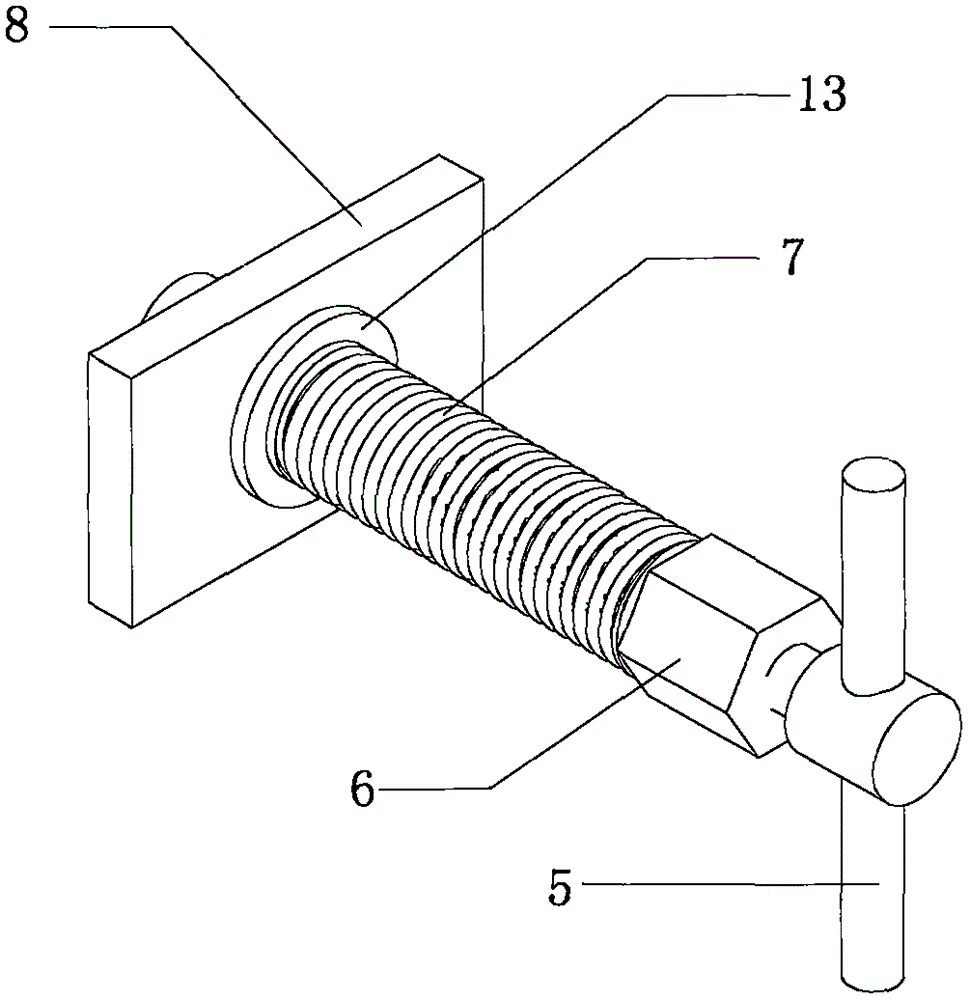

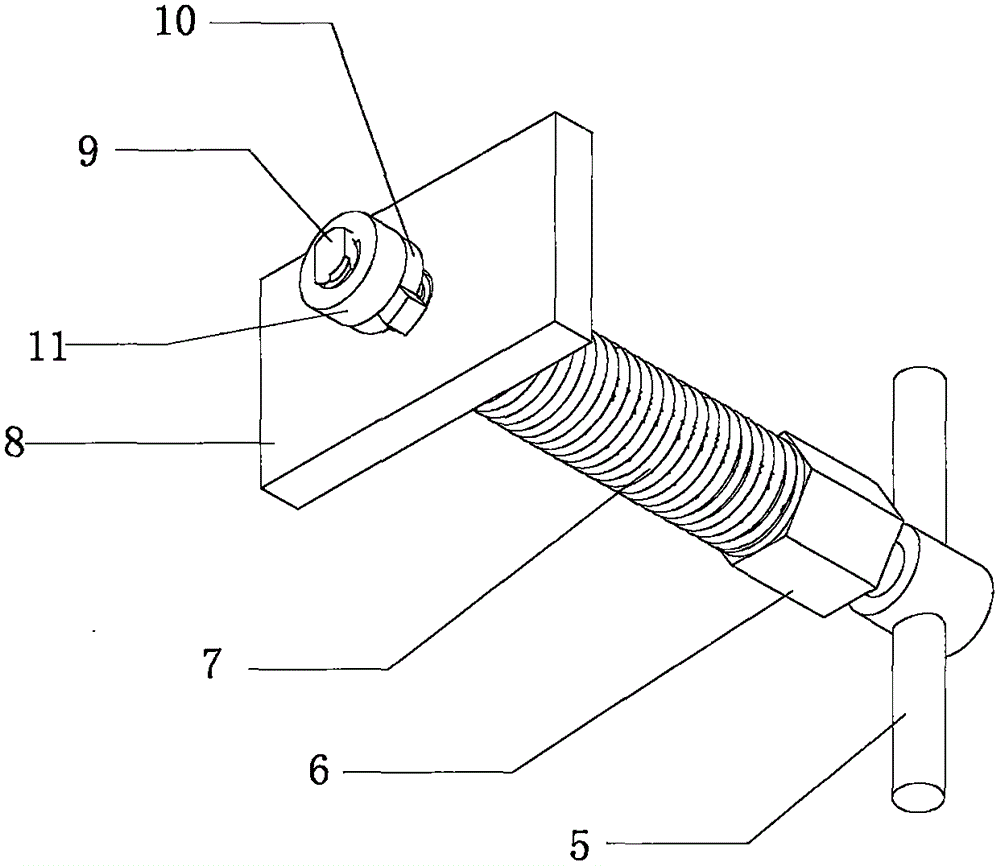

[0030] like Figure 2 to Figure 7 As shown in the figure, a tooling tool for quickly fixing a grouting sleeve includes a bolt 4 with a rolling thread. Cap 6, the bolt 4 at the lower end of the adjusting nut 6 is covered with a spring member 7, the bolt 4 at the lower end of the spring member 7 is provided with a template 8, the bottom of the bolt 4 is provided with a waist-shaped wire head 9, and the waist-shaped wire head 9 is fixed on the sleeve After clamping the board 10, use the fastening nut 11 to fix it.

[0031] A first spring washer (not visible in the figure) is arranged between the fixing card 10 and the fastening nut 11 .

[0032] A limiting collar 12 is also set between the lower part of the spring member 7 and the bolt 4 . A protruding outer limiting ring 13 is provided on the outer side of the lower end of the limiting collar 12 , and the outer limiting ring 13 serves as a washer for supporting the spring member 7 to move or slide on the bolt 4 .

[0033] The...

Embodiment 2

[0035] like Figure 8 As shown, a tool for quickly fixing a grouting sleeve includes a bolt 4' with rolling threads, characterized in that a handle 5' is installed at the top of the bolt 4', and a bolt 4' faces downward along the handle 5' There is an adjustment nut 6' on the upper end, the bolt 4' at the lower end of the adjustment nut 6' is covered with a spring member 7', the bolt 4' at the lower end of the spring member 7' is provided with a template 8', and the bottom of the bolt 4' is provided with a waist Shaped wire head 9', waist-shaped wire head 9' is put on the fixing card 10', and then fixed with the fastening nut 11'.

[0036] A second spring washer 16' is arranged between the spring member 7' and the template 8' as a washer for supporting the spring member 7' to move or slide on the bolt 4'.

[0037] In addition, in order to prevent the spring from clamping the hand during construction, an anti-clamping hand ring sleeve may be provided on the bolt at the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com