a brake drum

A technology for brake drums and brake parts, applied to brake drums, slack adjusters, etc., can solve the problems of large rotating centrifugal force, affecting the service life of bearings, increasing bearing burden, etc., to reduce rotating centrifugal force and external throwing force, and improve processing The effect of high efficiency and reduced burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

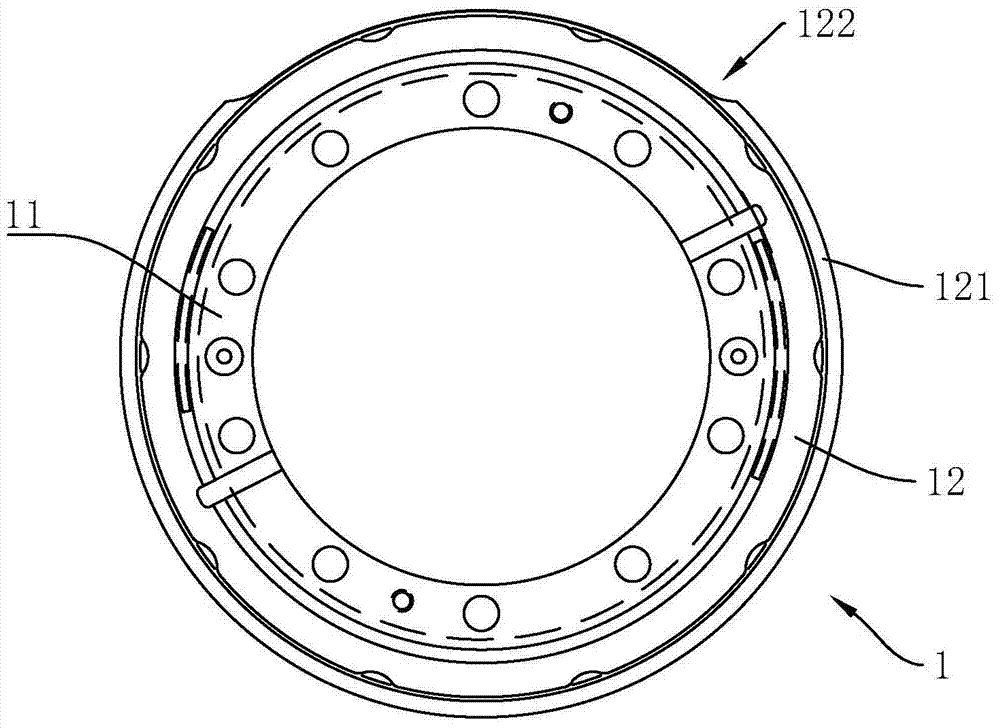

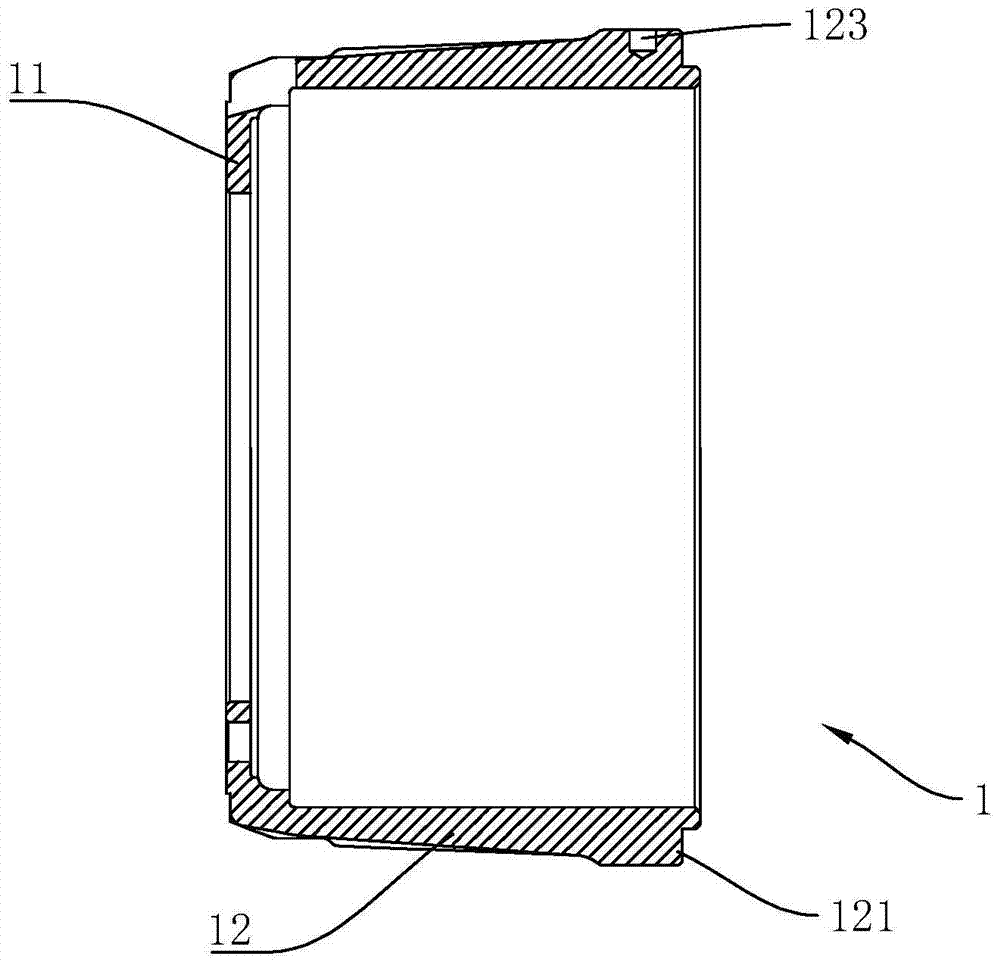

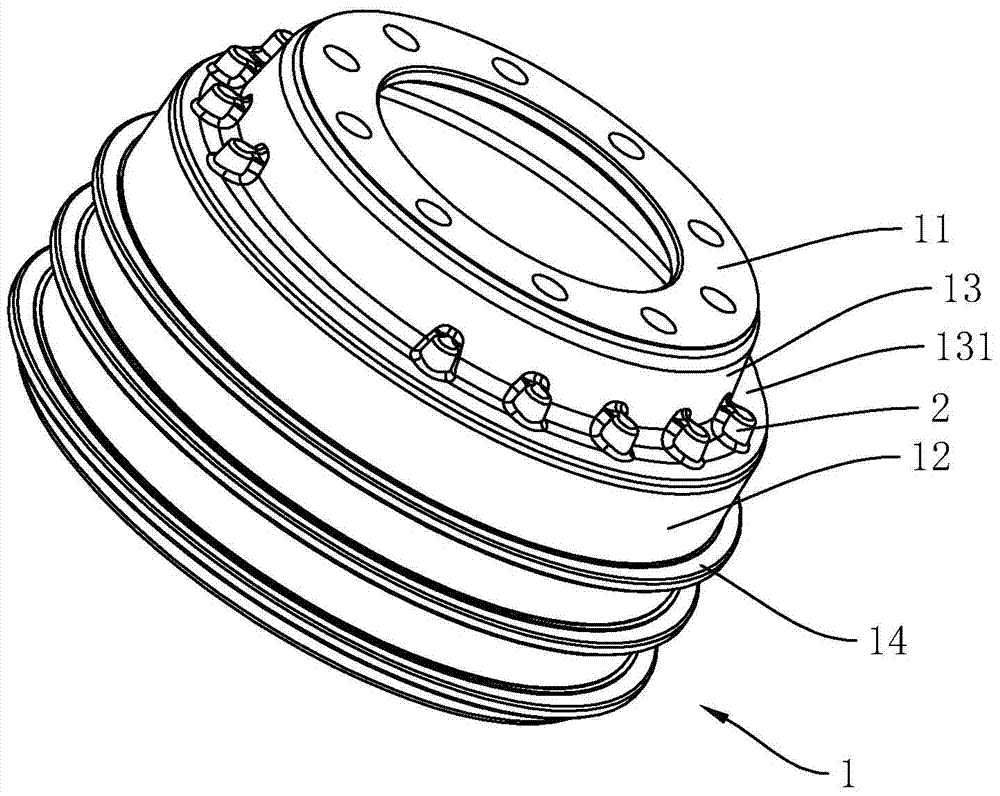

[0045] Such as Figure 3 to Figure 6 Commonly shown, a brake drum includes a casted brake drum body 1, the brake drum body 1 includes a hub connecting portion 11 for connecting with a wheel hub and a brake pad for cooperating with a brake shoe. part 12, a transition connection part 13 is provided between the hub connection part 11 and the brake part 12, a step part 131 is provided on the transition part 13, and a step part 131 is provided for adjusting the balance of the brake drum body 1. the balance department.

[0046] The balance portion includes a plurality of bosses 2 arranged on the transition connection portion 13 , and the bosses 2 extend toward the hub connection portion 11 . The formation process of the final finished brake drum is as follows: first, the brake drum body 1 is cast and formed, and at the same time, the bosses 2 are formed in an annular array on the transition connecting portion 13 (such as Figure 4 shown), and then according to the calculation of t...

Embodiment 2

[0050] Such as Figure 7 and Figure 8 Commonly shown, the specific structure of this embodiment is the same as that of Embodiment 1, the difference being:

[0051]The hoop 14 is a hoop 141 tightly fitted on the outer periphery of the brake part 12. A plurality of axially arranged annular ribs 143 protrude from the outer circumference of the hoop 141. The hoop between two adjacent annular ribs 143 A plurality of cooling grooves 142 are arranged circularly on the sleeve 141; the clamp 14 can be an aluminum clamp or a steel clamp. The hoop 14 with this structure has good covering ability on the brake part 12 and high working strength, and can effectively prevent fragments from splashing out after the brake drum body 1 is broken, thereby improving safety.

Embodiment 3

[0053] Such as Figure 9 and Figure 10 Commonly shown, the specific structure of this embodiment is the same as that of Embodiment 1, the difference being:

[0054] The balance part includes at least one counterweight body 3 fixed on the transitional connection part 13 (specifically: the stepped part 131) through the fastener 22, the counterweight body 3 is provided with a long hole 31, and the counterweight body 3 is a sheet structure and the weight body 3 is of a bent structure (that is, the bent portion 32 in the figure), the above can be regarded as a single embodiment.

[0055] As a preference, there are several protrusions 6 in an annular array on the transition connection part 13 (specifically: the stepped part 131), and the weight body 3 is installed on at least one protrusion 6 through a fastener 22. The specific structure is: the protrusion Block 6 is provided with connection hole 21, and this connection hole 21 is threaded hole, and this fastener 22 is the bolt o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com