Full heat exchange type fresh air machine

A technology of full heat exchange and fresh air fans, which is applied in the directions of space heating and ventilation, space heating and ventilation details, and household heating, etc. It can improve the use environment range, improve the efficiency of bypass ventilation, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

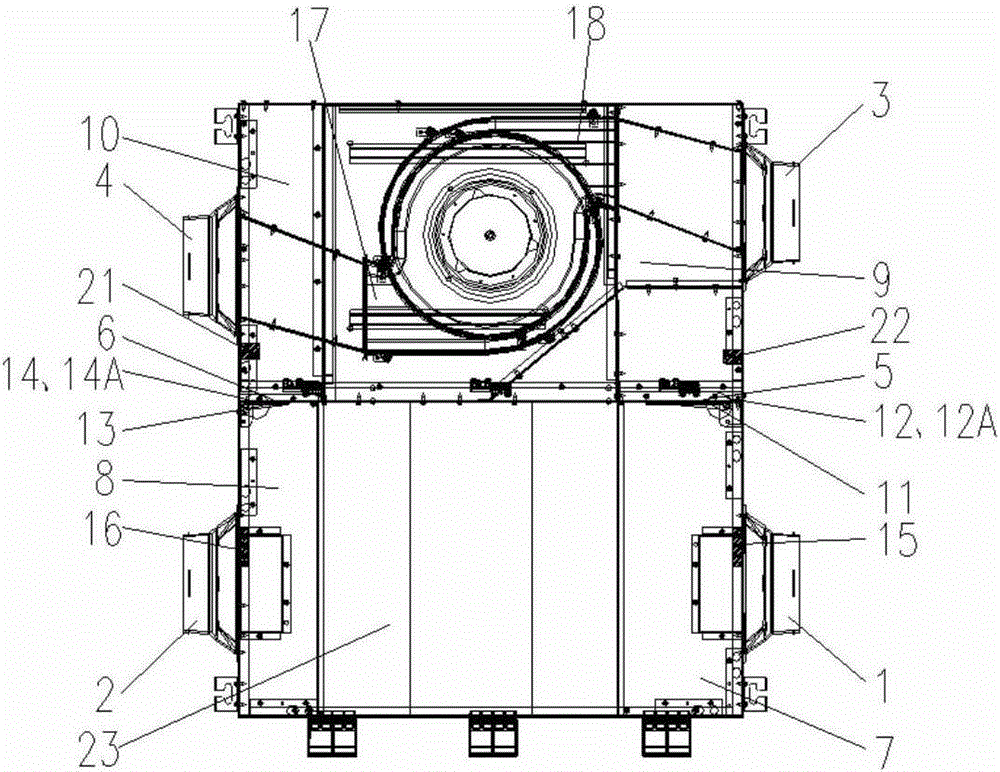

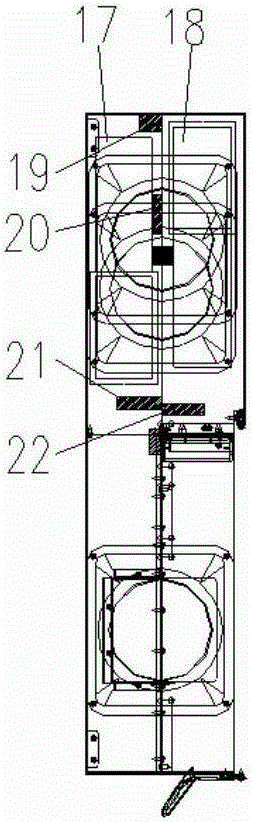

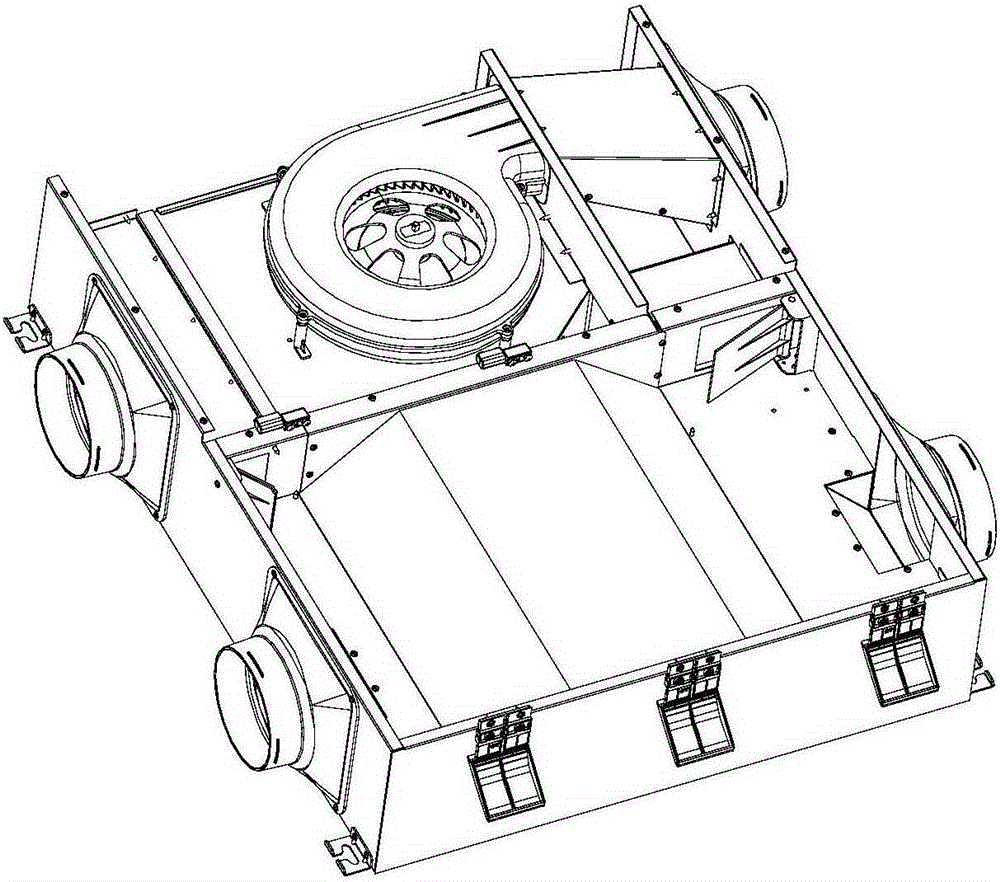

[0031] first see attached Figure 1A , 1B and figure 2 , the total heat exchange type fresh fan of the preferred structure of the present invention comprises fresh air inlet air chamber 7, exhaust air inlet air chamber 8, fresh air supply air chamber 9, exhaust air supply chamber 10, fresh air blower 17, exhaust blower 18 and full Heat exchange core body 23, wherein, fresh air enters air chamber 7, total heat exchange core body 23, fresh air supply air chamber 9 and fresh air blower 17 form fresh air path, exhaust air enters air chamber 8, total heat exchange core body 23, exhaust air The air supply air chamber 10 and the exhaust air blower 18 form an exhaust air passage. The full heat exchange fresh air blower of the present invention, for example, can have a box-shaped main body, and the side of the main body is provided with an air outlet that can communicate with the indoor and outdoor, for example, the outdoor fresh air inlet 1 connected to the fresh air inlet air chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com