Belt buckle

A buckle and elastic piece technology, applied in the direction of buckle, fastener, clothing, etc., can solve the problems of long horizontal length, unable to shorten the length, and unable to shorten the length of the elastic piece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described below with reference to the accompanying drawings.

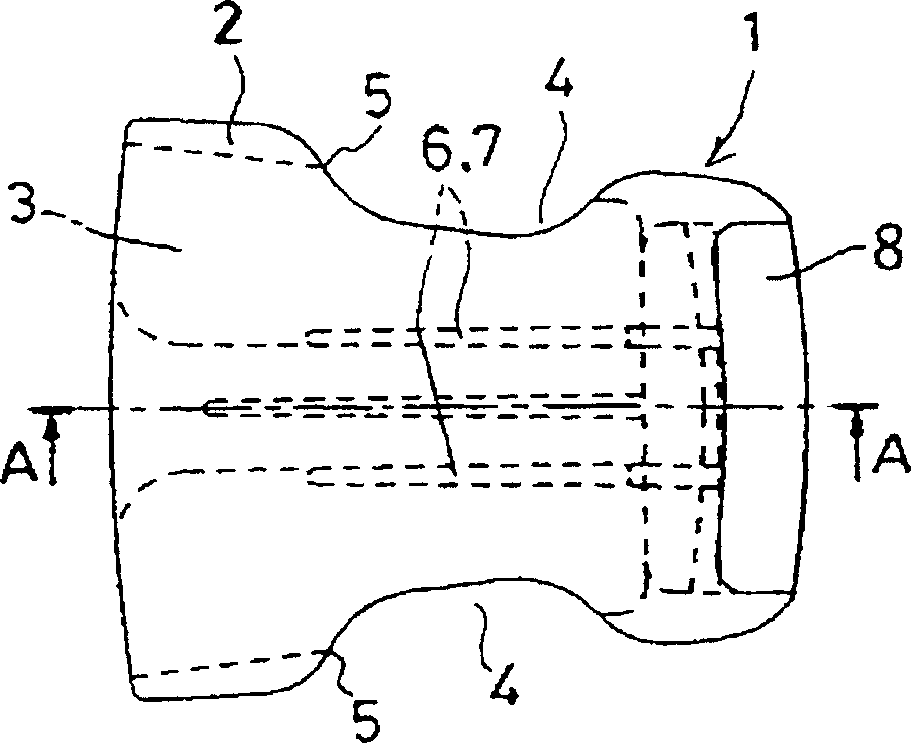

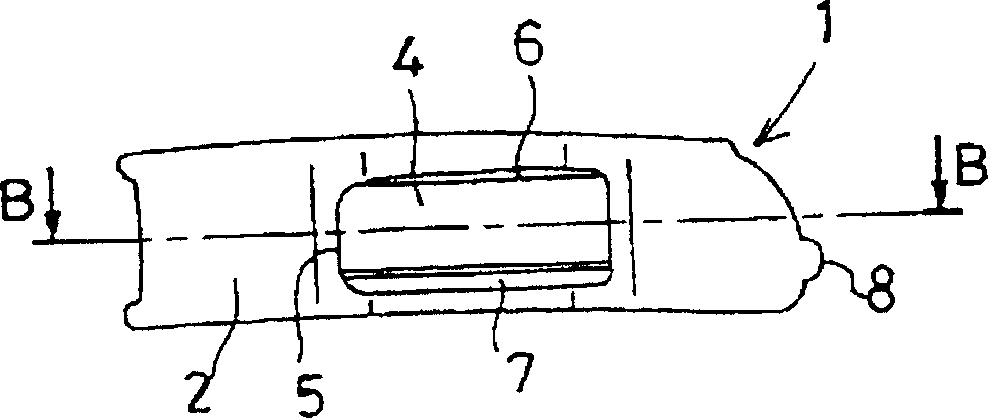

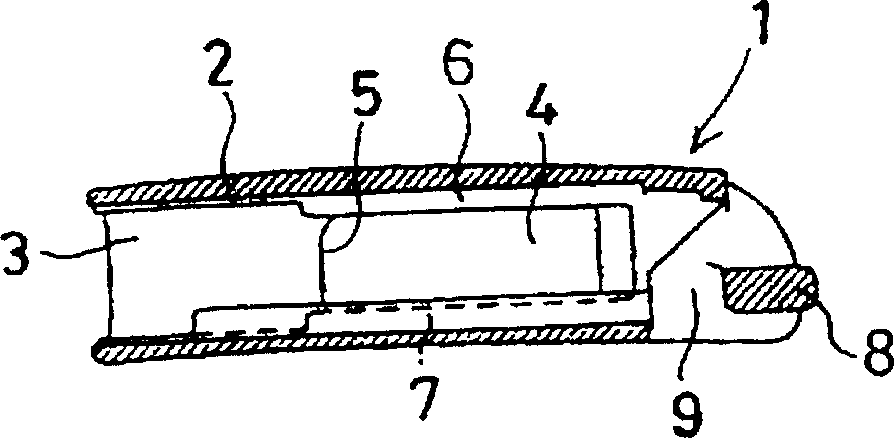

[0026] figure 1 It is a front view of a female part constituting a buckle according to an embodiment of the present invention, figure 2 for figure 1 The bottom view of the female part shown, image 3 for along figure 1 A cross-sectional view of the A-A line in, Figure 4 for along figure 2 Sectional view of line B-B in .

[0027] exist Figure 1~4 Among them, reference numeral 1 denotes a female part made of plastic, and the female part 1 is composed of a flat hollow tube 2 and a flat plate part 8. on the back end.

[0028] The hollow cylinder 2 is provided with an insertion hole 3 open from the front to the rear end, and an opening 4 is provided on the upper and lower walls, and the front side edge of the opening 4 constitutes a stopper 5 .

[0029] In addition, two guide ribs 6 are integrally provided on the inside of the front wall of the hollow tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com