Suction overflow gas-liquid distributor

A gas-liquid distributor, overflow technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of large pressure drop, large volume and complex structure of the medium, so as to reduce pressure drop and achieve gas-liquid distribution. The effect of uniform and enlarged spraying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

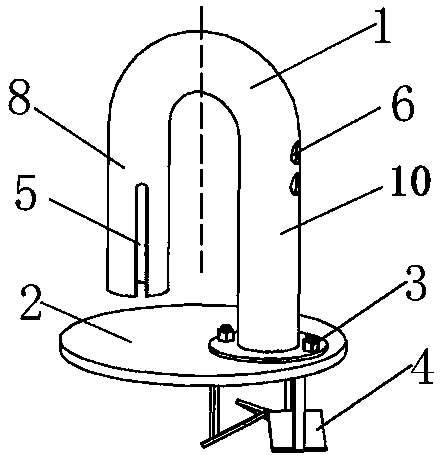

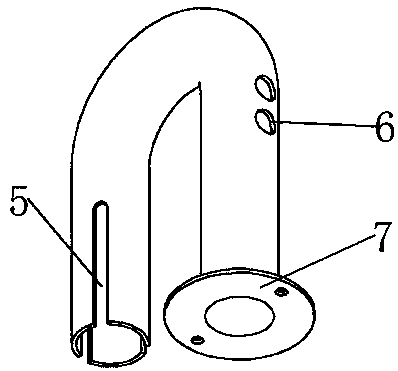

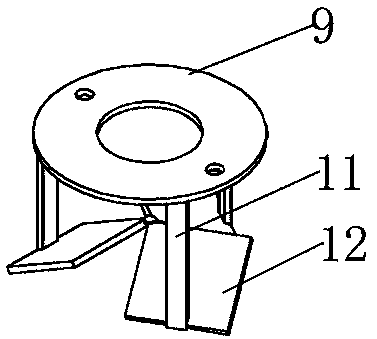

[0032] Such as Figure 1 to Figure 3 A kind of suction overflow type gas-liquid distributor shown, it comprises the elbow 1 that is installed on both sides of the opening of tray plate 2 by fastener 3 and breaker 4, and the two ends of elbow 1 are all Open, the length of the inlet section 8 of the elbow 1 is less than the length of the outlet section 10, the bottom of the inlet section 8 is evenly distributed with 3 strip-shaped slits 5, and the side wall of the outlet section 10 away from the inlet section 8 is provided with 2 The circular air inlet 6, the lowest position of the air inlet 6 is higher than the highest position of the slit 5, and the elbow 1 is fixed above the opening of the tray plate 2 through the first flange 7 installed at the bottom of the outlet section 10; The outlet section 10 of the elbow 1 , the opening of the tray plate 2 and the flow breake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com