Road vehicle dynamic weighing method and device

A dynamic weighing and vehicle technology, applied in the field of vehicle weighing, can solve problems such as large shaft assembly weight errors, increase the difficulty of cheating, and improve the effect of weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

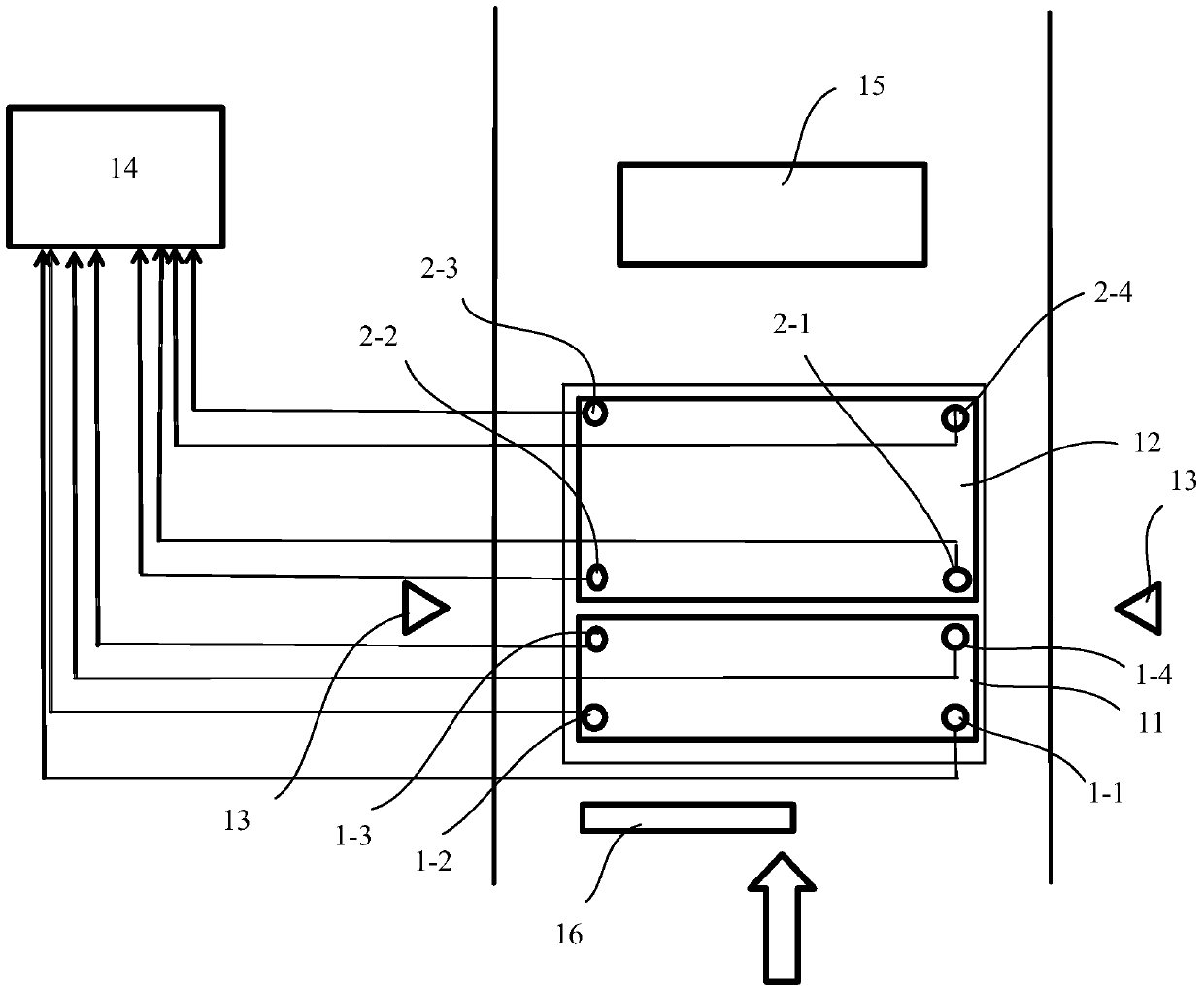

[0023] figure 1 A schematic diagram of a road vehicle dynamic weighing device according to an embodiment of the present invention is shown. Such as figure 1 As shown, the road vehicle dynamic weighing device 10 of this embodiment includes a first weighing platform 11, a second weighing platform 12, a light curtain 13, a weighing instrument 14, and a ground sensing coil 15 installed in the driveway And tire type recognizer 16 etc. The first weighing platform 11 and the second weighing platform 12 are placed in the same frame 17 or in the same foundation pit, and can be arranged forward and backward in the driving direction. figure 1 The figure shows that the second weighing platform 12 is at the front, and the first weighing platform 11 is at the rear. It will be appreciated that the reverse arrangement is also permissible.

[0024] The first weighing platform 11 is used to weigh a single axle of the vehicle, so the size of the first weighing platform 11 in the driving dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com