Film body, reverse injection molding method for film body, and reverse injection molding tool for film body

An injection molding, film technology, applied in the field of reverse injection molding tools, reverse injection molding, can solve problems such as expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

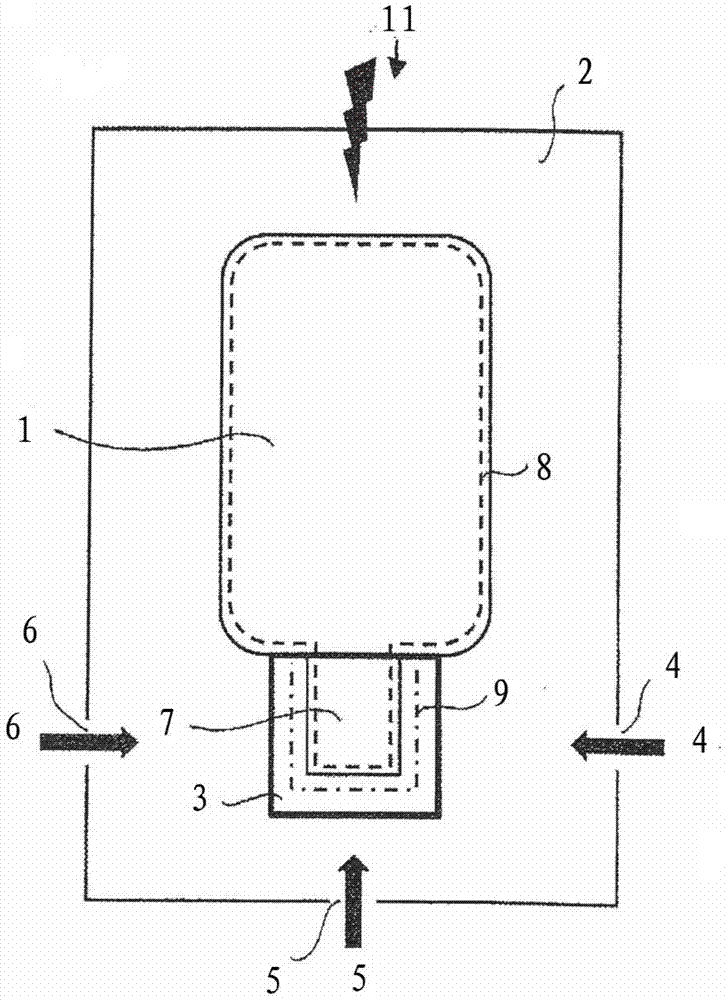

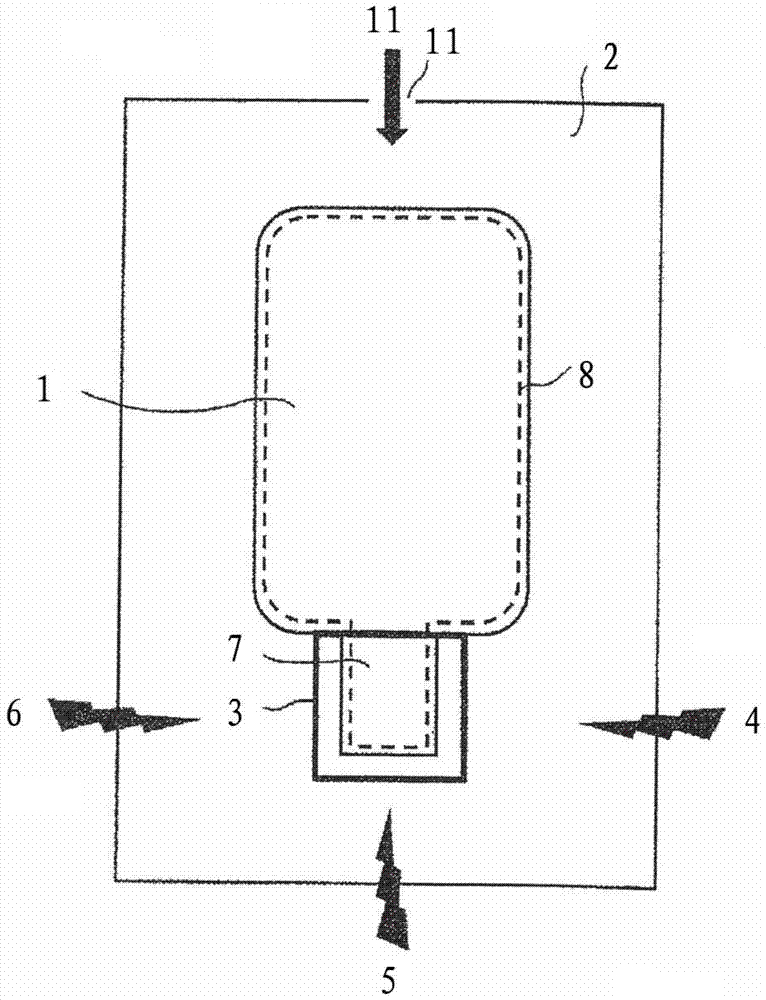

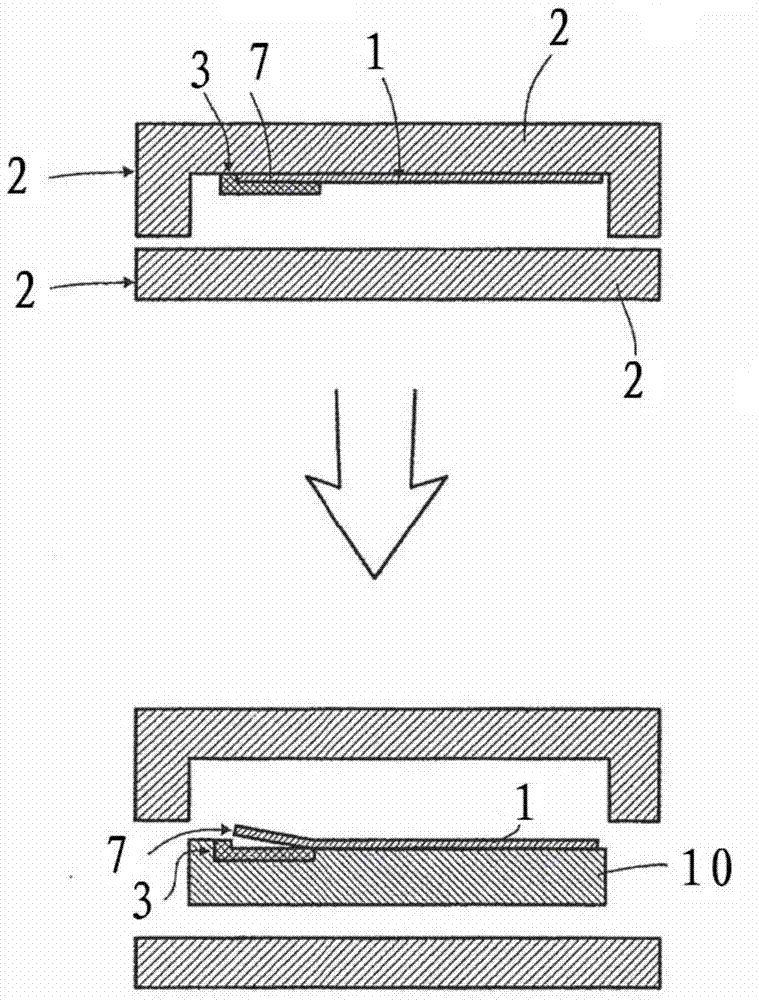

[0046] figure 1 The layer electrode 1 and the sacrificial film 3 inserted into the reverse injection molding tool 2 are shown. The layer electrode 1 with the tail 7 is held by a vacuum line 8 formed in the reverse injection molding tool 2 , while the sacrificial film 3 is held by a second vacuum line 9 different therefrom. This is necessary because in this embodiment example there is no coherent film body comprising both the layer electrode 1 and the sacrificial film 3 . Instead, layer electrode 1 as a first film and sacrificial layer 3 as a second film are present independently therefrom and only loosely arranged on top of each other without being connected to one another.

[0047] For reverse injection molding body 10( Figure 2b ) of the formation of reverse injection molding material injection according to the figure 1 The embodiment shown in is implemented by means of openings 4 , 5 or 6 . The direction from which back injection molding material (not shown) arrives in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com