Cardan shaft bearing

A universal joint shaft and bearing technology, applied in the field of universal joint shaft bearings, can solve the problems of high cost and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

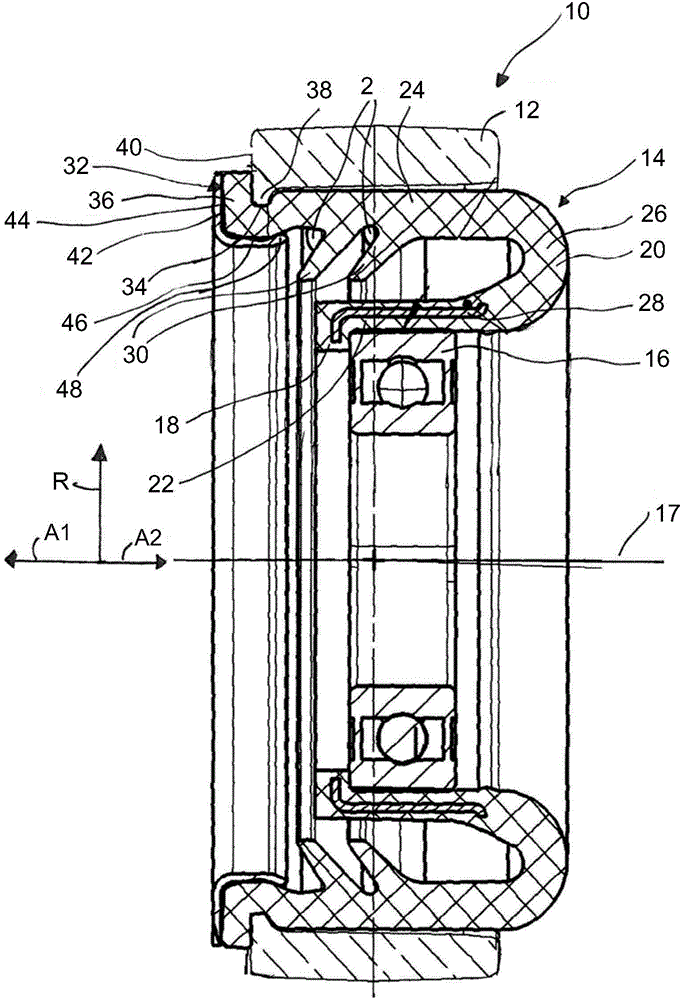

[0026] exist figure 1 A cross-section of a first embodiment of a cardan shaft bearing 10 according to the invention for supporting a cardan shaft, not shown, is shown in FIG.

[0027] The cardan shaft bearing 10 has a bearing seat 12 with a receiving bore 14 into which a rolling bearing 16 is inserted. An elastic body 20 is arranged between the rolling bearing 16 and the bearing housing 12 .

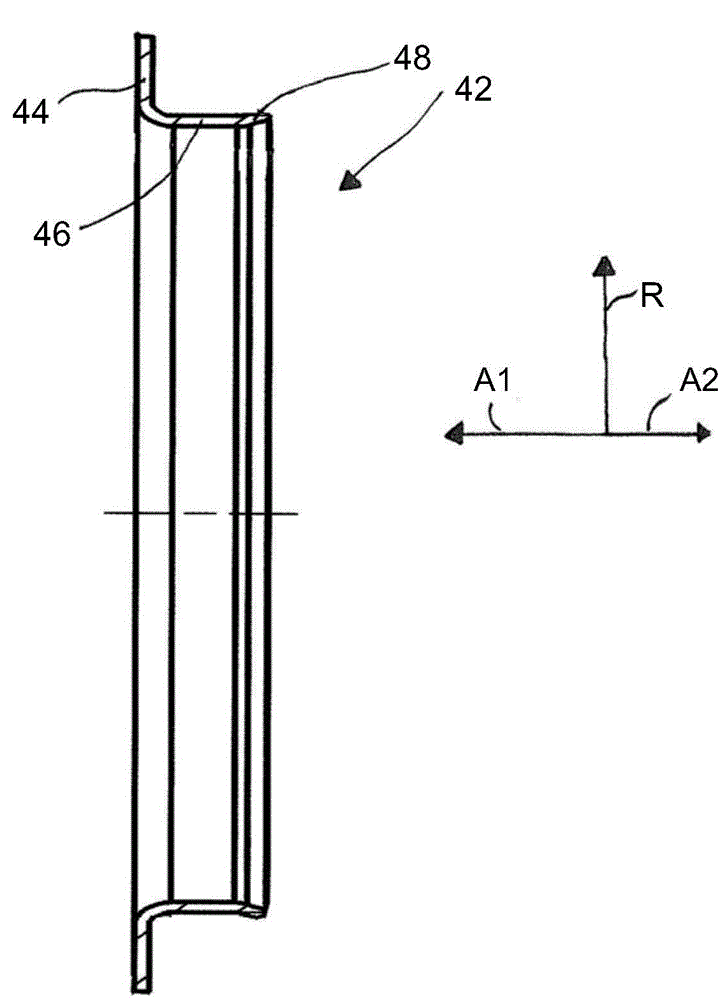

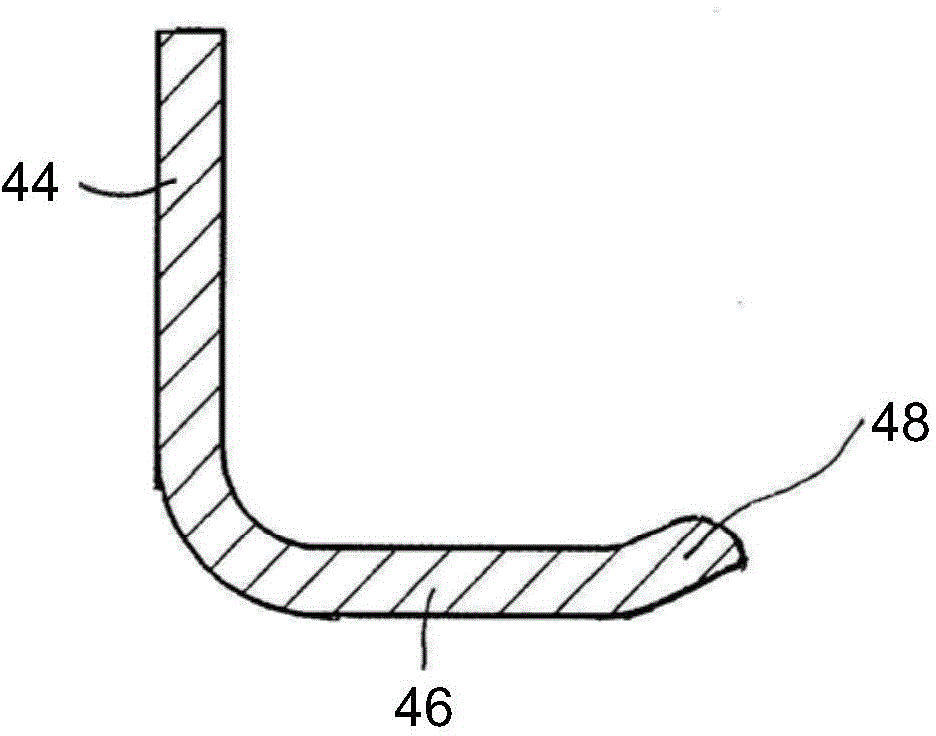

[0028] Such as figure 1 As shown, the elastomer body 20 has an approximately U-shaped cross-section and has a radially inner leg 22 and a radially outer leg 24 connected to each other by an approximately curved base 26 . The radially inner leg 22 now bears against the rolling bearing 16 . In particular, the radially inner leg 22 forms a receiving opening for the rolling bearing 16 . In order to increase the surface contact, an inner bushing 28 is inserted, preferably vulcanized, into the radially inner leg 22 . The inner sleeve 28 can now be connected to the elastomer body 20 in a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com