Composite barrier structure with self-healing ability

A technology with functional structure and capability, which is applied in the field of electroluminescent device preparation, can solve the problems of reducing the display quality and service life of OLED devices, unsatisfactory water and oxygen barrier effects, and degraded OLED devices, etc., achieving excellent water and oxygen barrier properties, good Good performance, uniformity and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

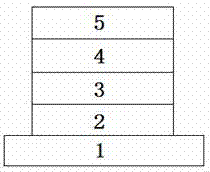

[0030] In this example, see figure 1 , a composite barrier structure with self-healing ability, has multiple functional structural layers, including sequentially stacking base Al on the substrate 1 2 o 3 Layer 2, Middle Aluminum Layer 3, Middle Al 2 o 3 Layer 4 and the outer dense structure layer, substrate 1 adopts polyimide PI flexible substrate, base Al 2 o 3 Layer 2 constitutes the first barrier layer, and the outer dense structure layer is the outer Al 2 o 3 Thin film layer 5, the outer dense structure layer can block the penetration of water and oxygen molecules, the middle Al 2 o 3 Layer 4 and the outer dense structure layer together constitute the second barrier layer, and the pure aluminum layer 3 is used as a repair agent layer, which can 2 o 3 Layer 2 and middle Al 2 o 3 When gap defects appear in layer 4, Al atoms are provided, and Al atoms are spontaneously oxidized at the defects to form Al 2 o 3 , to fill in the corresponding defects.

[0031] In t...

Embodiment 2

[0051] This embodiment is basically the same as Embodiment 1, especially in that:

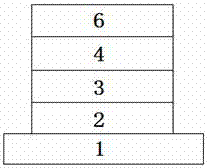

[0052] In this example, see figure 2 , the outer dense structure layer is the outer SiN X Layer 6. The difference between this example and Example 1 is that the top barrier layer uses PECVD to prepare SiN X Layer 6, SiN prepared by PECVD X It also has good barrier properties, and the combination of the two further enhances the water and oxygen barrier properties.

Embodiment 3

[0054] This embodiment is basically the same as the previous embodiment, and the special features are:

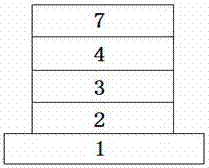

[0055] In this example, see image 3 , the outer dense structure layer is the outer SiO 2 Layer 7. The difference between this example and the previous examples is that the topmost barrier layer uses PECVD to prepare SiO 2 Layer 7, SiO prepared by PECVD 2 It also has good barrier properties, and the combination of the two further enhances the water and oxygen barrier properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com