Class d dry powder fire extinguishing agent

A technology of dry powder fire extinguishing agent and barrier agent, which is applied in the direction of fire prevention equipment, etc., can solve the problems of high fire extinguishing efficiency, difficult to clean up on site, easy to cause reburning, etc., achieve high nitrogen content, good flame retardant effect, and reduce hygroscopicity Effect

Active Publication Date: 2019-01-29

DAQING YINGBO FIRE FIGHTING EQUIP

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In the prior art, Class D dry powder fire extinguishing agents are generally divided into two categories, one is the special type, which is only suitable for certain or certain types of metal fires, and the applicable area is small, but it often has high fire extinguishing efficiency

The second is the general-purpose type, which has a wider range of applications, but has problems such as fire extinguishing speed and anti-resurgence, especially after fire extinguishing, resurgence is easy to occur, and the site is difficult to clean up.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

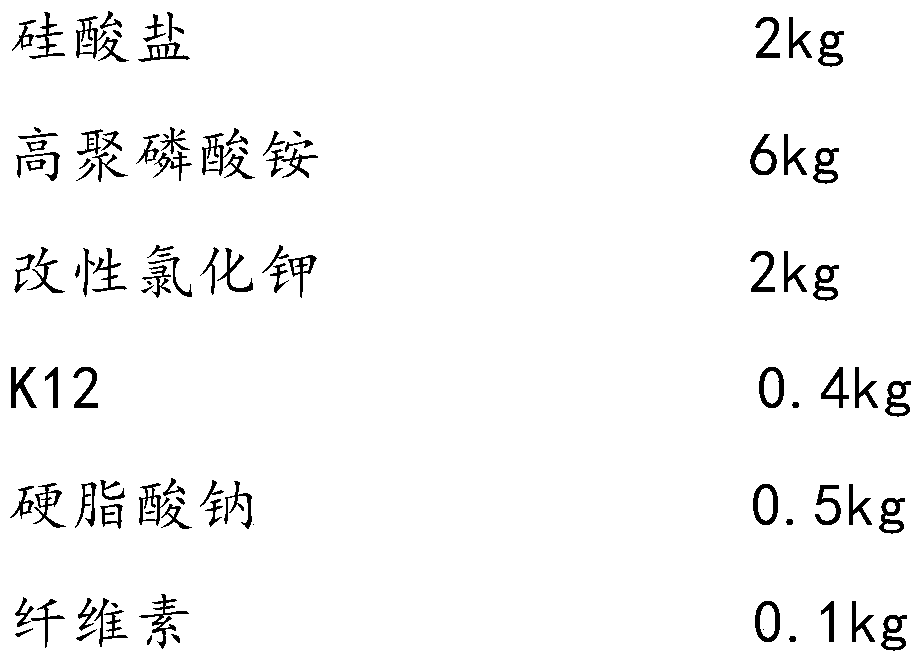

Embodiment 1

[0029] Composition:

[0030]

[0031] The preparation adopts conventional technology. The above-mentioned raw materials are mixed evenly in a pear-knife mixer. Carry out drying, cross-linking, and curing in a drying oven at 70-90°C to obtain the required fire extinguishing agent. The preparation methods of the following examples are the same.

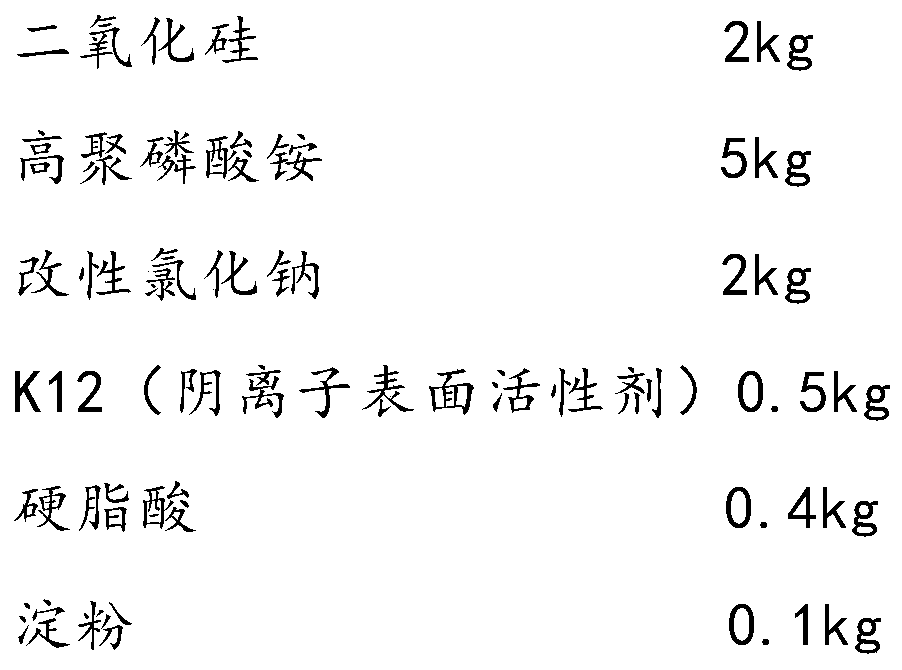

Embodiment 2

[0033] Composition:

[0034]

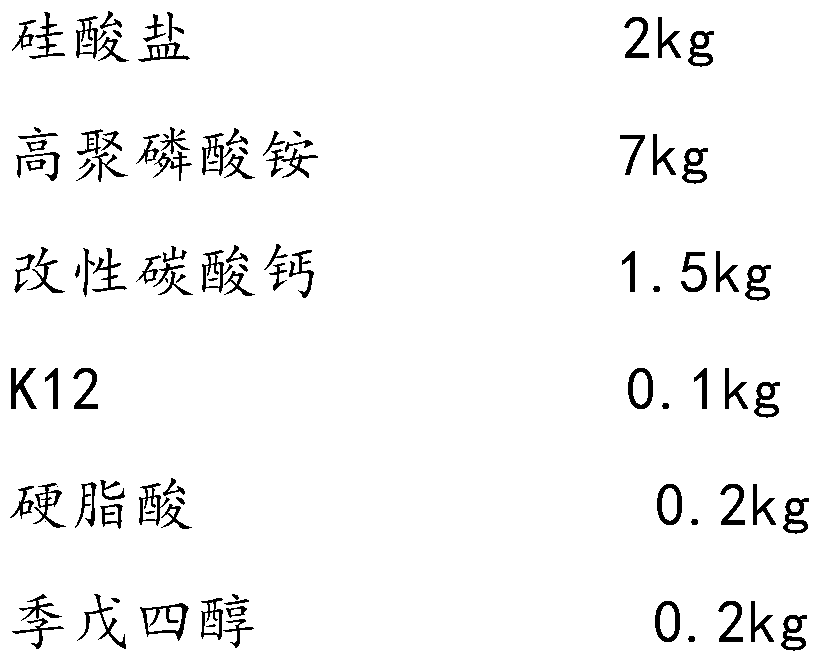

Embodiment 3

[0036] Composition:

[0037]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a D type dry powder extinguishing agent. The D type dry powder extinguishing agent is prepared from, by weight, 10-20 parts of a blocking agent, 50-70 parts of a foaming agent, 15-20 parts of a filling agent, 1-5 parts of a stabilizing agent, 1-5 parts of impregnating compounds and 1-5 parts of catalysts.

Description

technical field [0001] The invention relates to a class D dry powder fire extinguishing agent. Background technique [0002] With the continuous development and progress of science and technology, the raw materials and procedures of our life and industrial production have made great progress compared with the past. Special metal raw materials such as potassium, titanium, magnesium, sodium and lithium, and alkylaluminum catalysts have also become very important parts of people's lives and production. The fires caused by the above substances are called Class D fires. This kind of fire is a very rare and special kind of fire caused by the combustion of metal substances. A large number of casualties, it is quite difficult to extinguish. [0003] For Class D fires, non-combustible materials such as dry sand, diatomaceous earth, graphite, or vermiculite powder are traditionally used to cover or absorb them to block combustion. The fire extinguishing speed is slow and the efficie...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A62D1/02

Inventor 陈杨许梦笛王家喜

Owner DAQING YINGBO FIRE FIGHTING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com