Piezoelectric jet type precise quantitative dispensing device and dispensing method thereof

A technology of piezoelectric spraying and dispensing devices, which is applied to the device and coating of surface coating liquid, which can solve the problems of insufficient deformation and affecting the dispensing quality, so as to improve dispensing accuracy and dispensing quality , Improve the effect of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

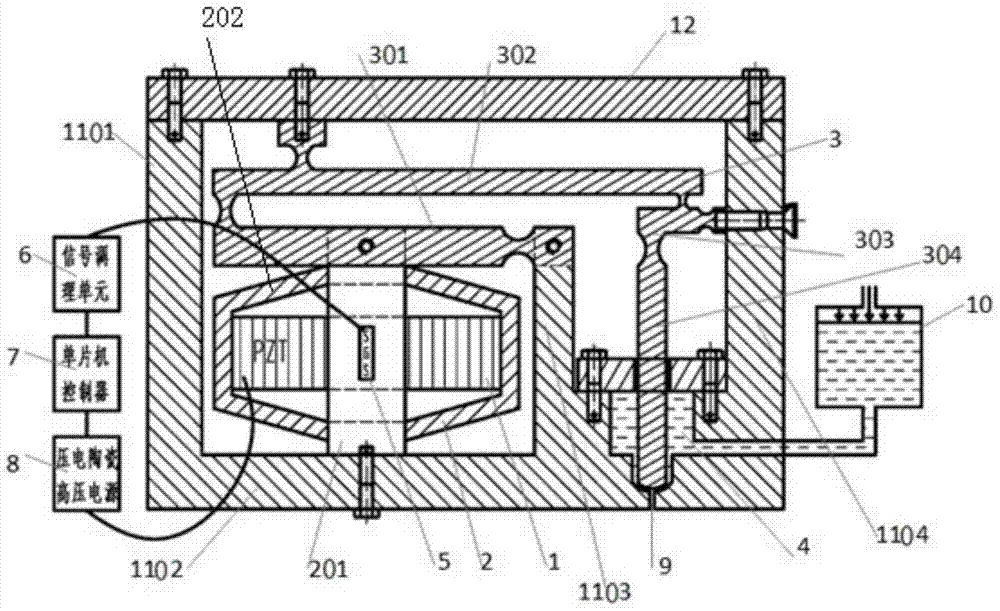

[0015] like figure 1 As shown, the piezoelectric jet type precise quantitative dispensing device includes a piezoelectric stack PZT driver 1, a primary amplification mechanism 2, a triple amplification mechanism 3 and a mechanical base;

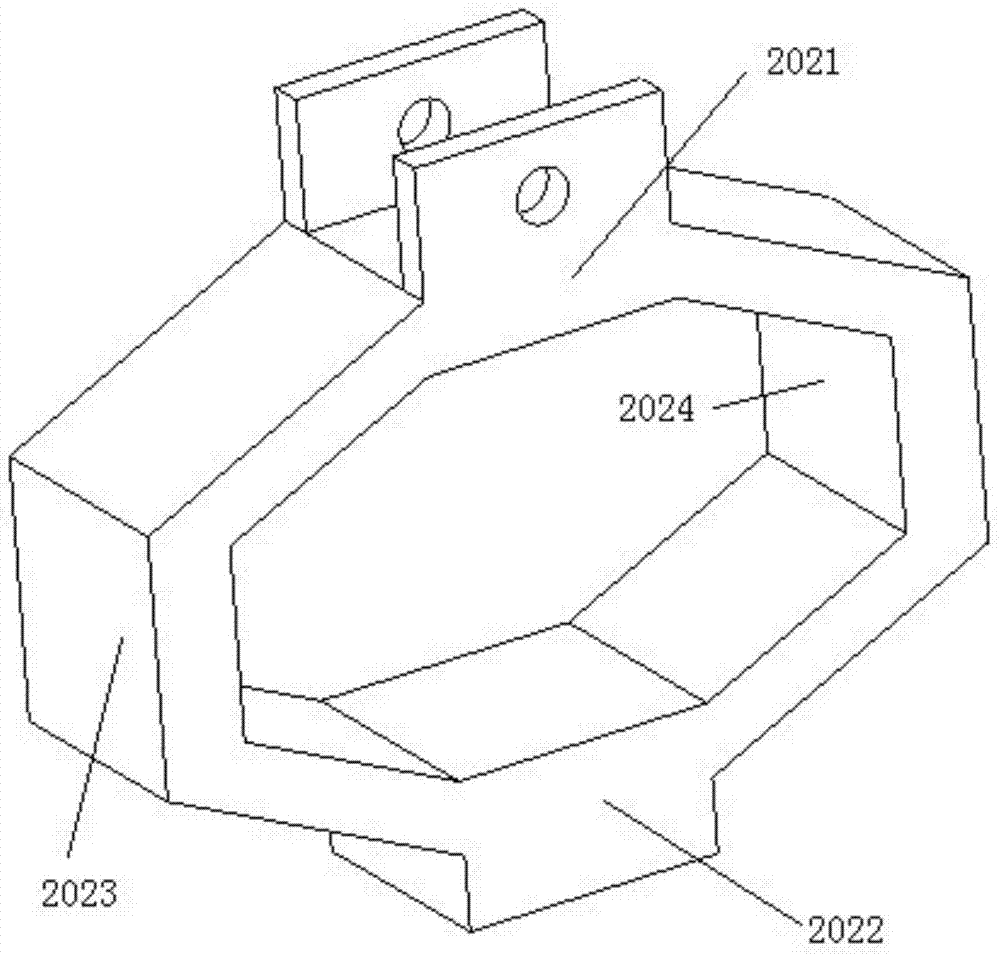

[0016] The primary amplification mechanism 2 adopts the triangular amplification principle. The primary amplification mechanism 2 includes an elastic amplification mechanism body 202 and two elastic metal sheets 201. The elastic amplification mechanism body 202 is an integral structure cut by wire. The two elastic metal sheets 201 Using 65Mn material with relatively large elastic modulus, the piezoelectric stack PZT driver 1 is embedded in the body 202 of the elastic amplification mechanism through interference fit; the piezoelectric stack PZT driver 1 is connected to the piezoelectric ceramic high-voltage power supply 8; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com