High-pressure mixing fluid pump

A high-pressure mixing and fluid pump technology, used in pumps, piston pumps, liquid variable-capacity machines, etc., can solve the problems of small thrust, poor sealing, and difficult displacement, and achieve high thrust, good sealing, and accurate position. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

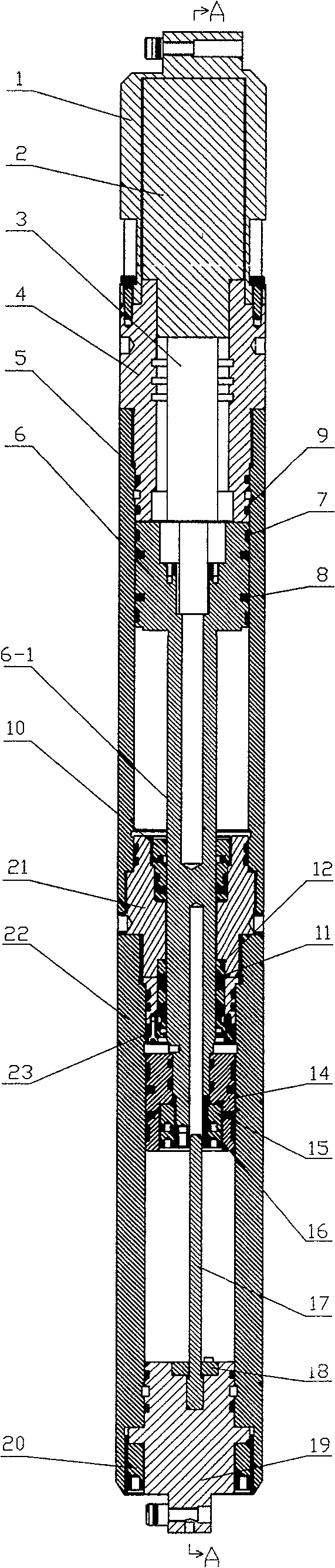

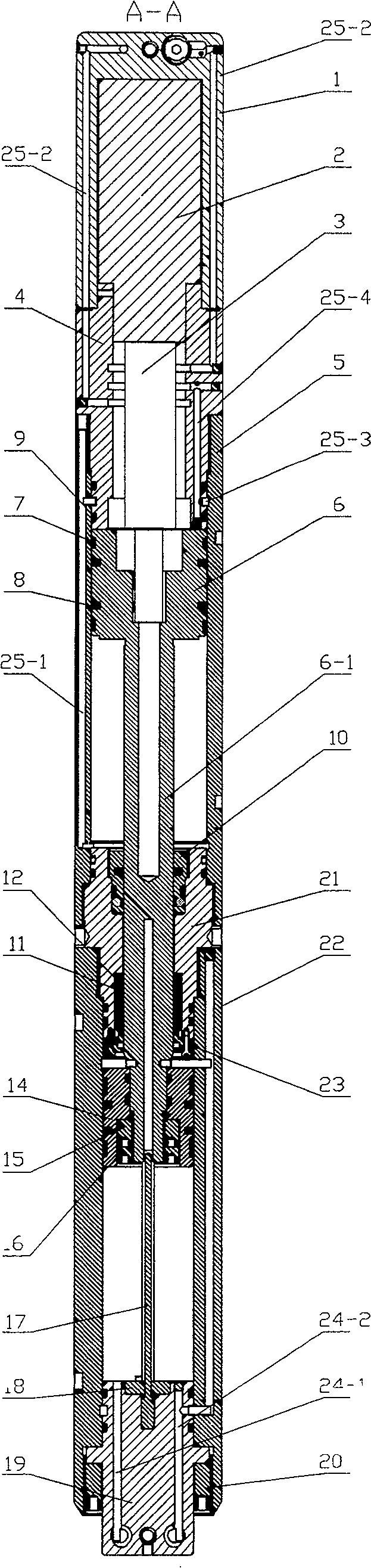

[0010] The present invention will be described in detail below with reference to the accompanying drawings and the best embodiment.

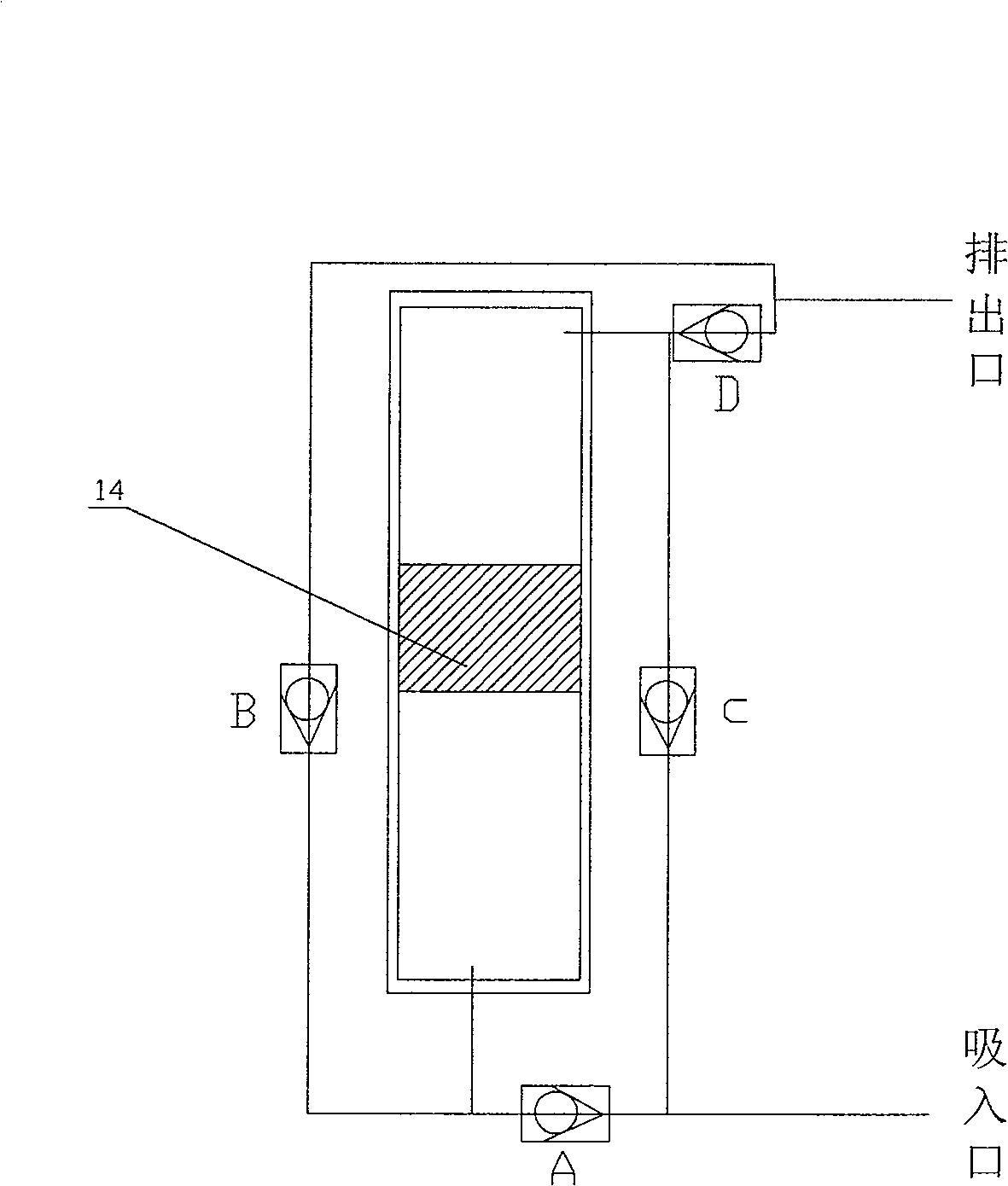

[0011] refer to figure 1 and figure 2 , the high-pressure mixed fluid pump of this embodiment consists of a front adapter 1, a stepping motor 2, an internal control body 3, a control joint 4, an oil cylinder 5, an oil cylinder piston 6, a wear ring 7, a gray ring 8, and a sealing ring 9 , sealing ring 10, dustproof ring 11, guide ring 12, sliding piston 14, first locking ring 15, second locking ring 16, guide rod 17, fixed disk 18, adapter 19, locking ring 20, connector 21, mud cylinder 22, fixed ring 23 form. The oil cylinder 5 and the mud cylinder 22 are threadedly connected to the upper and lower ends of the connector 21, and sealing rings are respectively arranged between the connector 21, the oil cylinder 5 and the mud cylinder 22. The upper end of the oil cylinder 5 is connected with the control joint 4 , the upper end of the control j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com