Roll gap adjusting device for straightener

An adjustment device and straightening machine technology, applied in the field of straightening machine equipment, can solve the problems of increased load on the roll gap adjustment device, frequent failures, large displacement errors, etc., and achieve simple and compact structure, accurate and controllable displacement, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

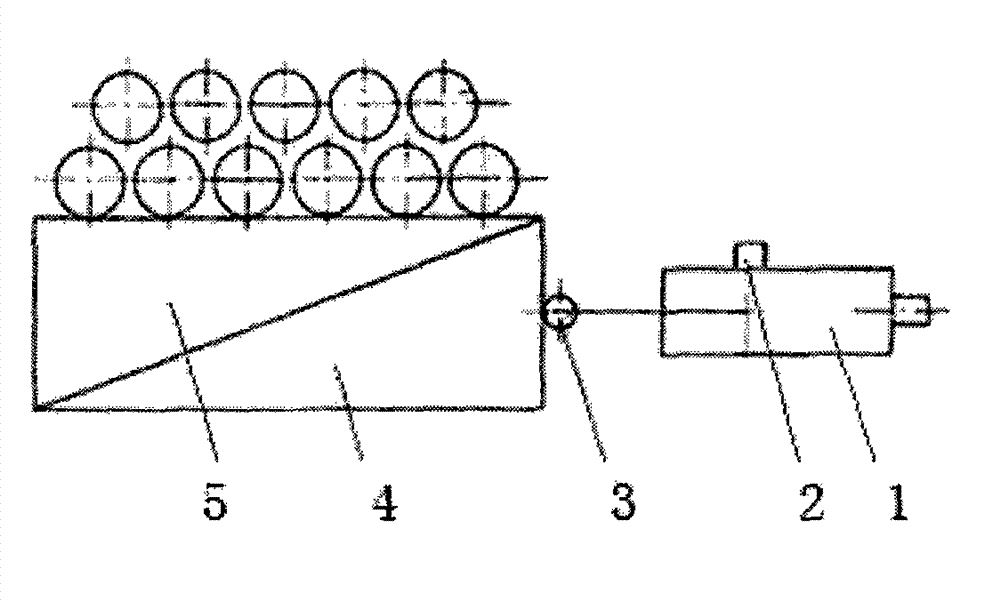

[0010] like figure 1 As shown, the present invention includes an upper slant wedge 5 and a lower slant wedge 4 that fit each other, and the lower slant wedge 4 is connected to the hydraulic cylinder 1 through a pivot pin 3, and the hydraulic cylinder 1 is provided with a position sensor 2 to work At this time, the hydraulic cylinder 1 drives the lower wedge 4 to move, thereby driving the lower roller system connected to the upper wedge 5 to rise or fall. The staff sets the movement amount of the lower wedge 4, and the movement signal is determined by the After the position sensor 2 detects, it is sent to the PLC. After the PLC calculates and confirms that it is equal to the set displacement, it issues a stop command to complete the roll gap adjustment.

[0011] The above is only a preferred embodiment of the present invention, but the scope of protection of the present invention is not limited thereto. Anyone familiar with the technical field within the technical scope disclos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com