Reliability detection device for metal welding part capable of collecting blanking material and its application method

一种金属焊接、检测装置的技术,应用在测量装置、使用施加重复力/脉动力测试材料强度、分析材料等方向,能够解决摩擦力大、缺乏收集断裂金属板装置、无法准确测量金属焊缝冲击力以及冲击力矩的大小等问题,达到移动效率增加、位置准确可控、便于可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

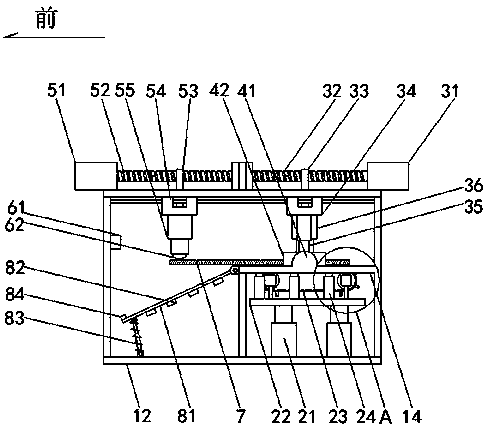

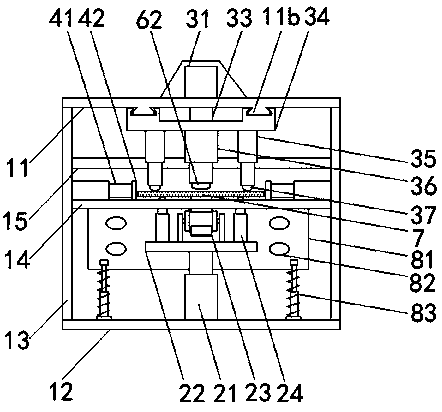

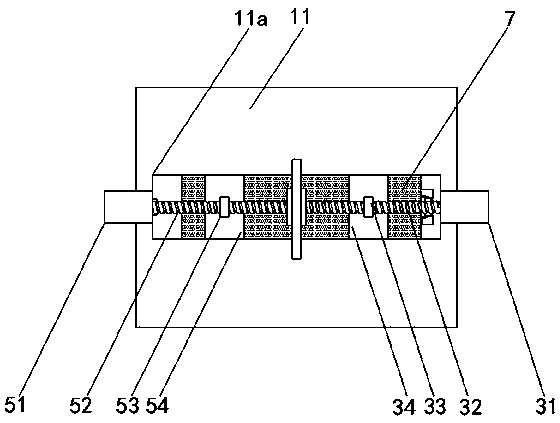

[0051] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0052] It should be noted that the "front and back" directions mentioned in the manual are the same as those figure 1 The front and rear directions shown in are the same.

[0053] The metal welding part reliability detection device capable of collecting blanking is characterized in that:

[0054] It includes upper and lower base plates (11, 12) arranged in parallel, and the upper and lower base plates (11, 12) are supported and connected by pillars 13, and a workbench 14 is also provided above the rear half of the lower base plate 12, so that The middle part of the upper bottom plate 11 is provided with a moving through hole 11a along the front-rear directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com