Clamping device with parallel clamping jaws

A clamping device and clamping jaw technology, applied in the field of clamping devices, can solve problems such as rupture of rubber hoses, achieve the effect of equal force and avoid damage and rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

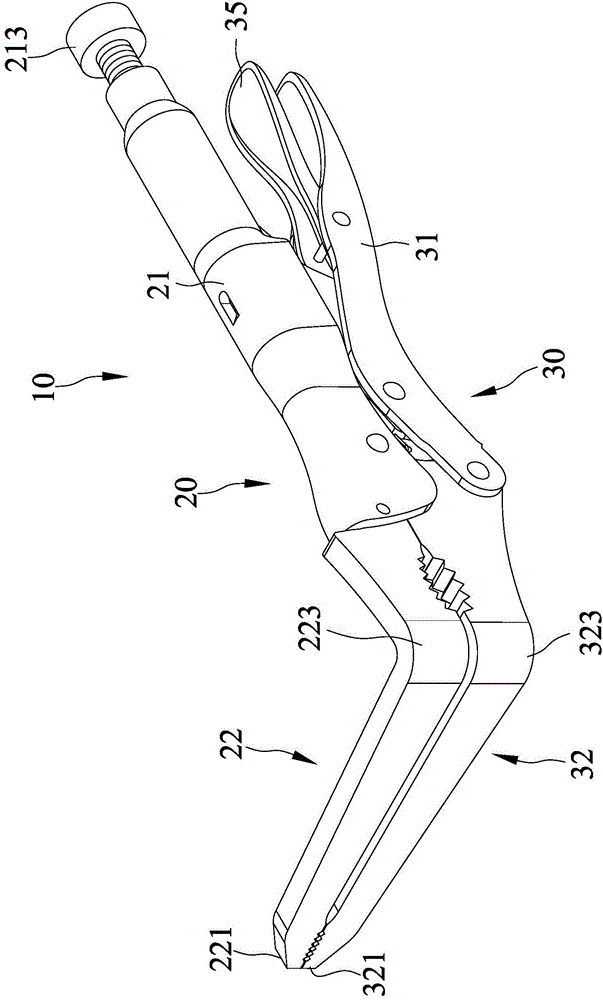

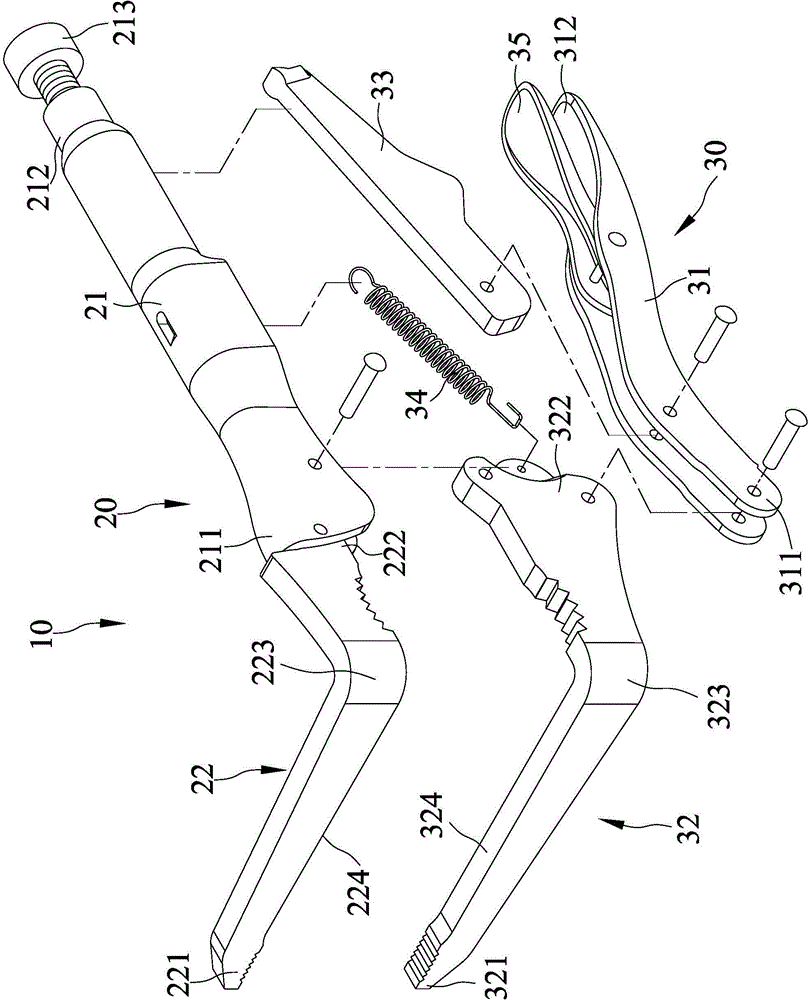

[0028] refer to figure 1 and figure 2 Shown is a three-dimensional appearance view and three-dimensional exploded view of the first embodiment of the clamping device of the present invention with jaws parallel to each other. The clamping device 10 of the present invention includes a first clamper 20 and a second clamper 30; wherein:

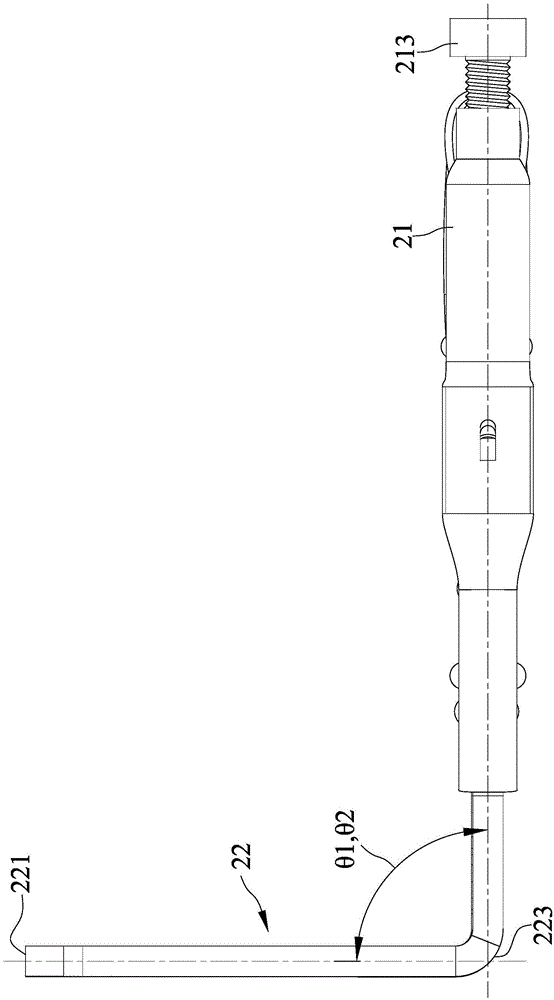

[0029] Please continue to refer to Figure 3 to Figure 5 As shown, it is a top appearance view, a side view appearance view and a cross-sectional structure view of the clamping device of the present invention whose jaws are parallel to each other. The first holder 20 includes a first handle 21 and a first jaw 22, the first handle 21 is provided with a connecting end 211 and a holding end 212 away from the connecting end 211, the first A handle 21 is screwed with an adjustment member 213 at the handle end 212. The adjustment member 213 can selectively rotate relative to the first handle 21 and move synchronously. When the adjustment member 213...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com