Top block structure for brake caliper lever mechanism

A lever mechanism and brake caliper technology, which is applied to the operating mechanism of railway vehicle brakes, railway braking systems, railway car body parts, etc. , the effect of improving efficiency and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments.

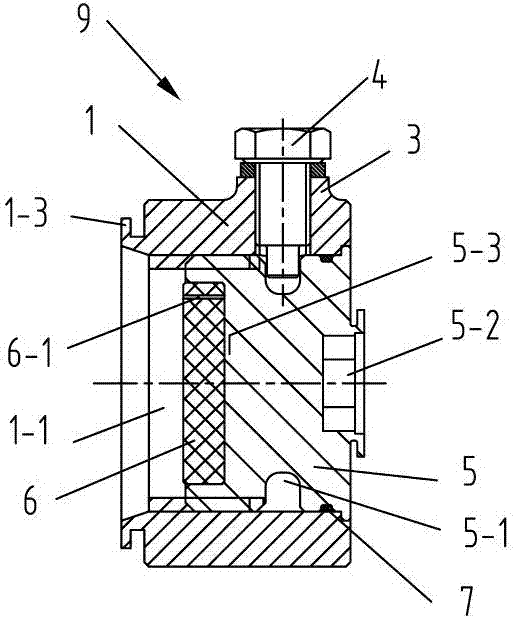

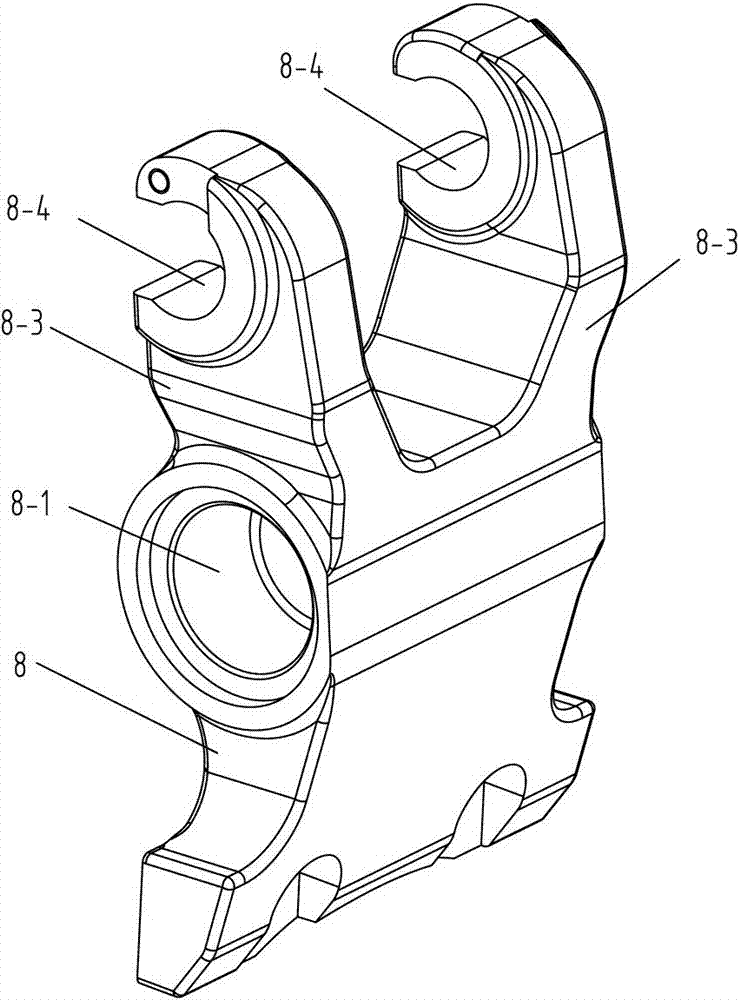

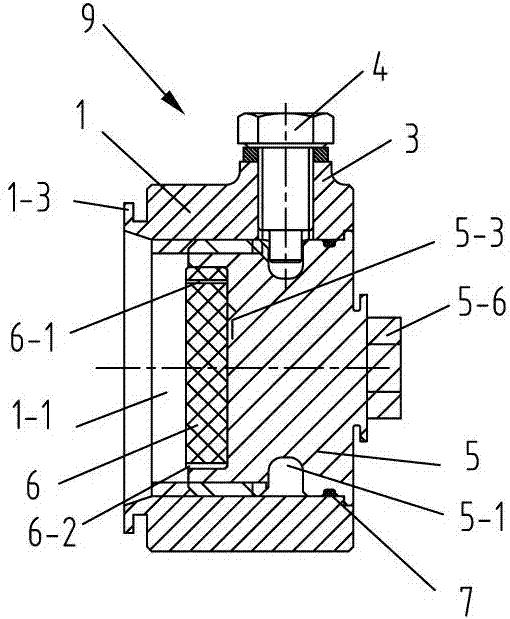

[0031] Such as Figure 1~9 As shown in , 11, a jacking block structure for brake caliper lever mechanism has a jacking block body 1, and the jacking block body 1 has two coaxial connecting shafts 2, and the connecting shaft 2 and the jacking block body 1 Installed or made into one piece, and located on the outer wall of the top block body 1, the top block body 1 has a radial positioning hole 3-1, and the positioning hole 3-1 is threadedly connected with the stop screw 4.

[0032] The top block body 1 is provided with a mounting hole 1-1, the mounting hole 1-1 is equipped with a fixed screw plug 5, and the front part of the fixed screw plug 5 is threadedly connected with the internal thread of the mounting hole 1-1, The outer peripheral wall of the fixed screw plug 5 is provided with a circumferential limit groove 5-1, and one end of the limit scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com