Lever Mechanism of Rail Transit Brake Caliper

A technology of brake calipers and rail transportation, which is applied to the operating mechanism of railway vehicle brakes, railway braking system, railway car body parts, etc., can solve the problems of inconvenient operation, increased maintenance cost, easy loss, etc. Low, high efficiency, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments.

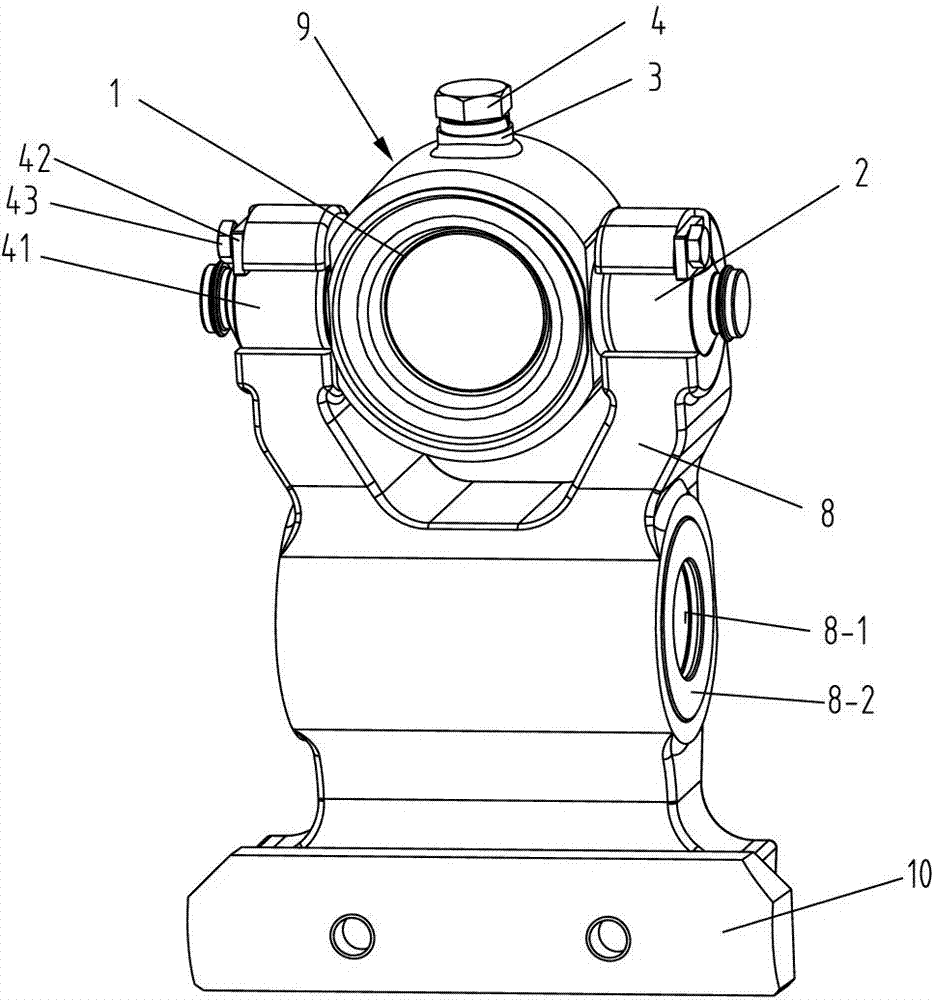

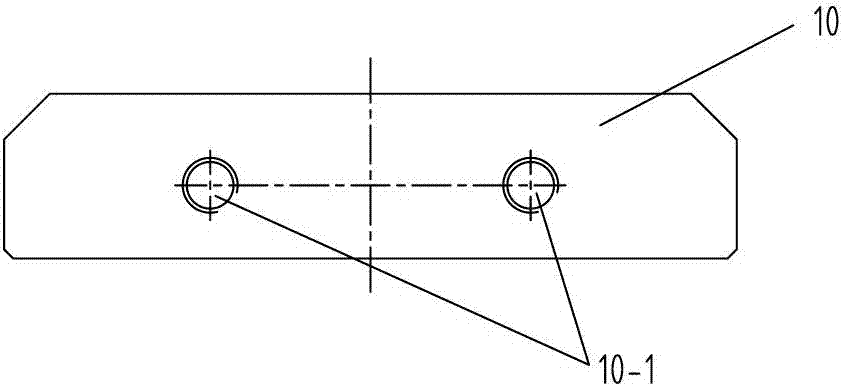

[0035] Such as Figure 1~9 , shown in 12, a kind of lever mechanism of rail transit brake caliper has lever body 8, and the middle part of described lever body 8 has shaft hole 8-1, and one end of lever body 8 also has top block mechanism 9, so The jacking mechanism 9 has a jacking body 1, and the jacking body 1 has two coaxial connecting shafts 2. On the outer wall of the top block body 1, there is a radial positioning hole 3-1 on the outer wall, and the positioning hole 3-1 is threaded with the stop screw 4; the top block body 1 has a mounting hole 1 -1, the mounting hole 1-1 is equipped with a fixed screw plug 5, the front part of the fixed screw plug 5 is threaded with the internal thread of the mounting hole 1-1, and the outer peripheral wall of the fixed screw plug 5 is provided with The circumferential limiting groove 5-1, one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com