Top block structure applied to braking clamp lever mechanism

A lever mechanism and brake caliper technology, which is applied to the operating mechanism of railway vehicle brakes, railway braking systems, railway car body parts, etc., can solve the problems of increased maintenance costs, unrelieved, easy to wear, etc., to improve efficiency , low maintenance cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and the given embodiments.

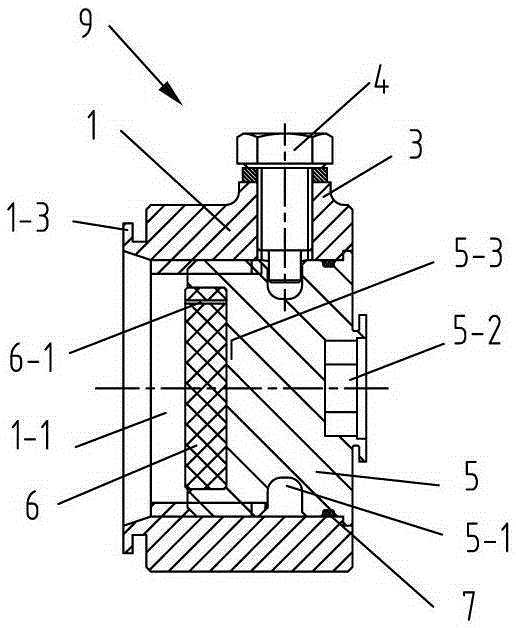

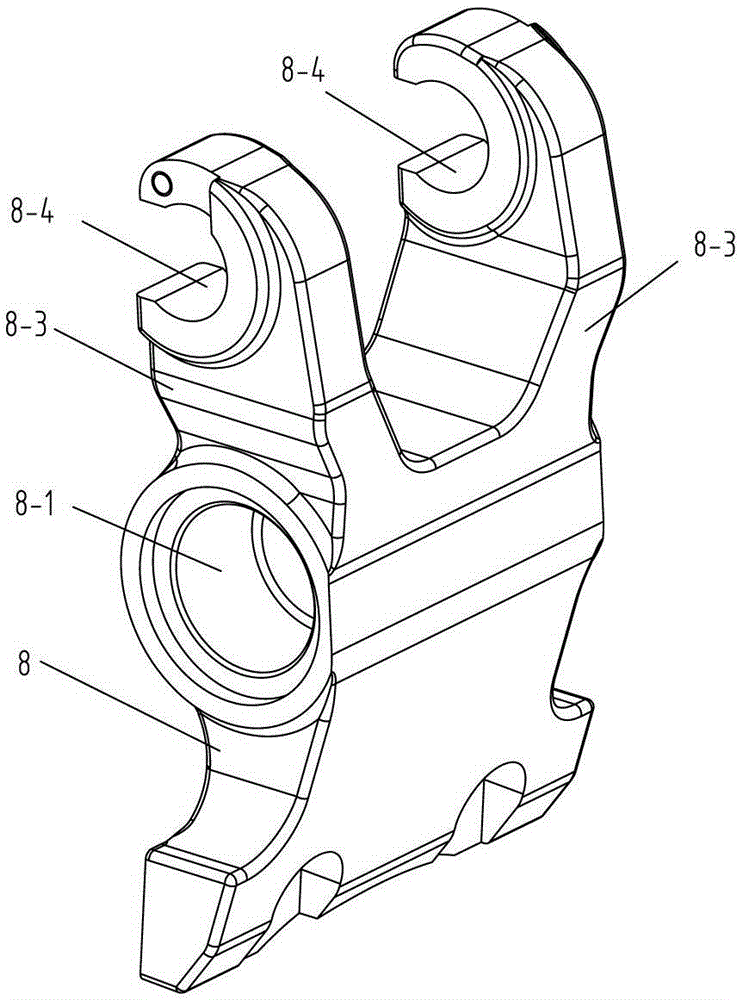

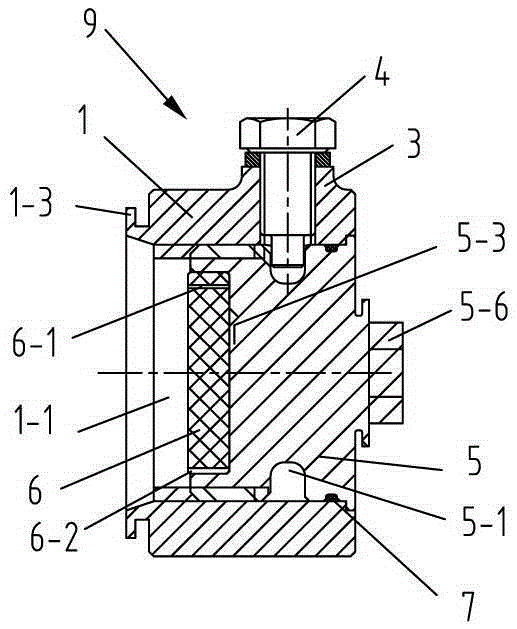

[0031] like Figures 1~9 , 11, a top block structure for a brake caliper lever mechanism, with a top block body 1, the top block body 1 has two coaxial connecting shafts 2, the connecting shaft 2 and the top block body 1 The top block body 1 is provided with radial positioning holes 3-1, and the positioning holes 3-1 are threadedly connected with the limit screws 4.

[0032] The top block body 1 is provided with an installation hole 1-1, a fixing screw plug 5 is installed in the installation hole 1-1, and the front part of the fixing screw plug 5 is threadedly connected with the internal thread of the installation hole 1-1, The outer peripheral wall of the fixing screw plug 5 is provided with a circumferential limiting groove 5-1, and one end of the limiting screw 4 extends into the circumferential limiting groove 5-1, which plays a certain r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com