Walking mechanism of grass-grasping machine

A technology of walking mechanism and grass catcher, which is applied in the field of grass catcher, which can solve the problems of easily damaged tires, non-walking, large turning radius, etc., and achieve the effects of prolonging service life, improving passing performance and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

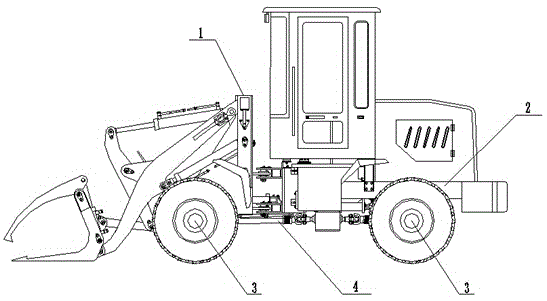

[0012] Such as figure 1 As shown, the walking mechanism of the grass catcher includes a hub bracket 2 installed on the bottom of the grass catcher frame 1;

[0013] The hub bracket 2 is connected to the universal wheel 3 through the hub bracket oil cylinder 4 .

[0014] The walking mechanism of the grass grabber drives the universal wheel 3 through the hub bracket oil cylinder 4 on the hub bracket 2, so that the universal wheel 3 can independently adjust the walking angle and trajectory according to the terrain, which significantly improves the passing performance of the grass grabber and reduces the number of tires. friction.

[0015] Further, the front and rear wheels installed on the hub bracket 2 are universal wheels 3 . Significantly improves the passing performance of the grass catcher.

[0016] Further, the universal wheel 3 is a wide-body universal wheel. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com