Phosphite antioxidant and preparation method thereof

A phosphite and antioxidant technology, applied in the field of antioxidants and their preparation, can solve problems such as environmental pollution and human injury, and achieve the effects of reducing production costs and simplifying technological processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Pump 1mol triphenyl phosphite and 1mol tetramethylpiperidinol into the esterification kettle, add 3g K 2 CO 3 , stirring, under the protection of nitrogen, vacuumize to -0.1MPa, heat up to 95°C, and keep warm for 2 hours; when the effluent condensed by the condenser on the top of the kettle is less, add 2mol of dodecylphenol, and continue to heat up to 220°C , heat preservation reaction until there is no effluent, cool to 60°C, release the vacuum with nitrogen, collect 700g of dodecylphenol disubstituted product at the bottom of the kettle, calculated as triphenyl phosphite, the yield is 98.6%, and the product purity is 99.0% .

Embodiment 2

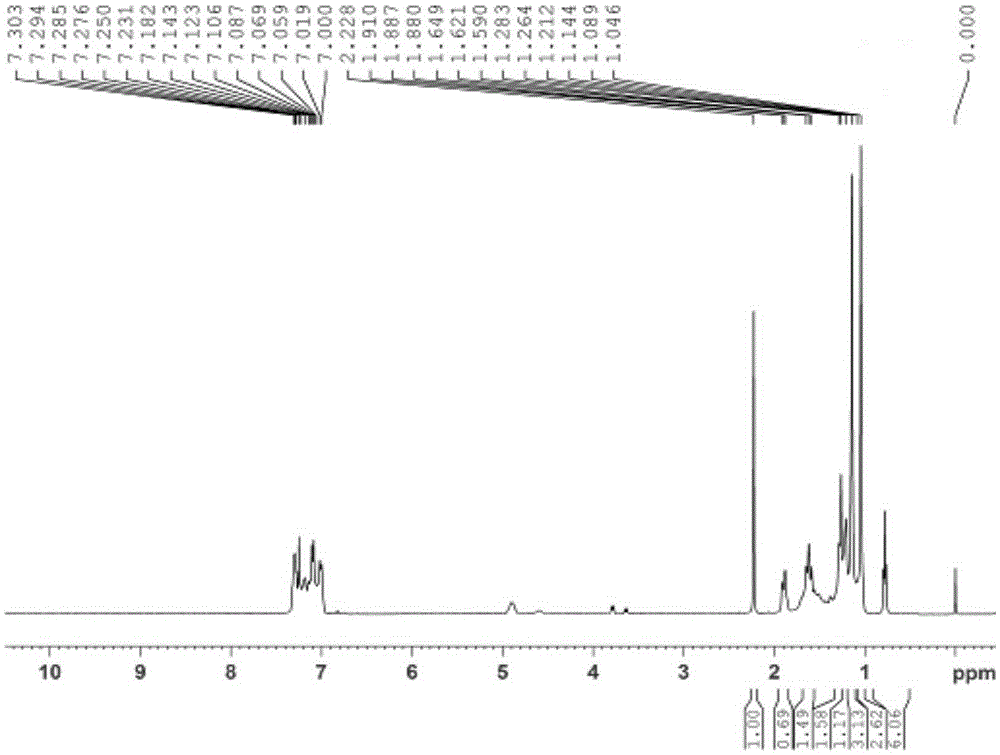

[0057] Pump 10mol triphenyl phosphite and 15mol pentamethylpiperidinol into the esterification kettle, add 62gK 2 CO 3 Stir, under the protection of nitrogen, evacuate to -0.1MPa, heat up to 95°C, and keep warm for 5 hours; when the effluent condensed by the condenser on the top of the kettle is less, add 11mol of dodecylphenol, and continue to heat up to 125-225°C ℃, heat preservation reaction until there is no effluent, lower the temperature to 60 ℃, release the vacuum with nitrogen, collect the bottom product, and obtain dodecylphenol monosubstituted product B5498g, based on triphenyl phosphite, the yield is 98.9%, the product 99.2% purity. B product in solvent CDCl 3 middle 1 HNMR such as figure 2 shown.

Embodiment 3

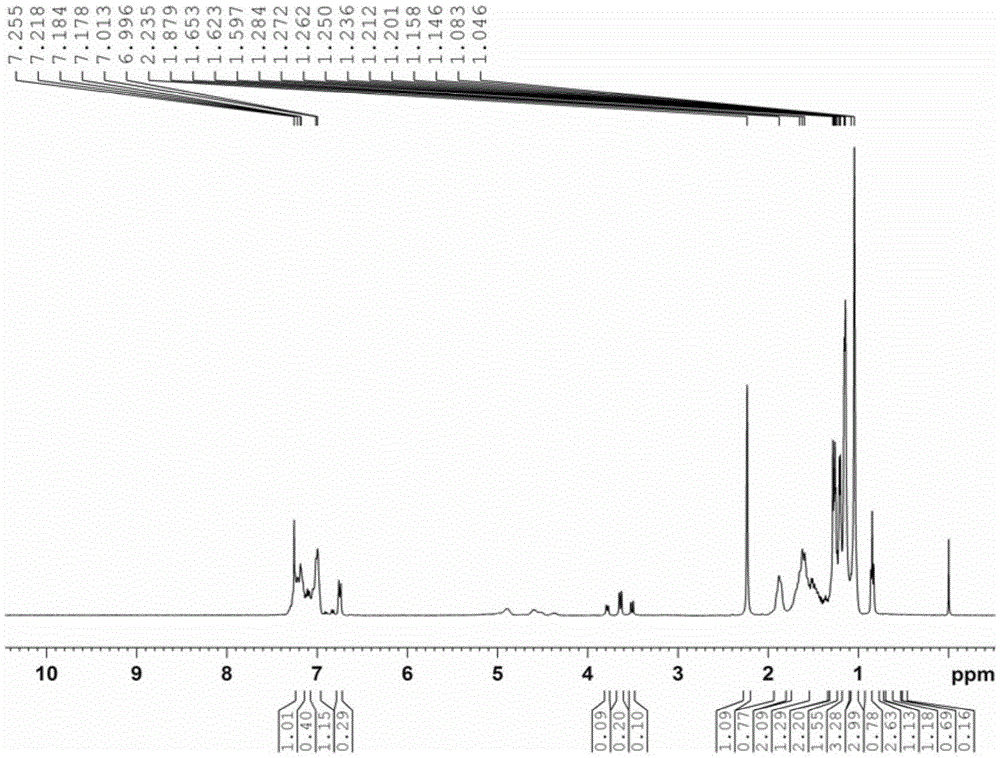

[0059] Pump 5mol triphenyl phosphite and 6mol pentamethylpiperidinol into the esterification kettle, add 8gK 2 CO 3 Stir, under the protection of nitrogen, evacuate to -0.1MPa, heat up to 95°C, and keep warm for 5 hours; when the effluent condensed by the condenser on the top of the kettle is less, add 12mol dodecylphenol, and continue to heat up to 125-225°C ℃, heat preservation reaction until there is no effluent, lower the temperature to 60 ℃, release the vacuum with nitrogen, collect the product at the bottom of the kettle, and obtain the disubstituted product of dodecylphenol A3580g, based on triphenyl phosphite, the yield is 98.9%, the product 99.4% purity. A product in solvent CDCl 3 middle 1 HNMR such as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com