A top drive cement head

A cement head and waist technology, which is used in wellbore/well components, earthwork drilling, sealing/packaging, etc., can solve the problems of low comprehensive capacity, poor applicability, and many specifications of cement heads, and achieve torsion-bearing capacity. The effect of high height, large hook load, avoiding the risk of climbing wiring and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

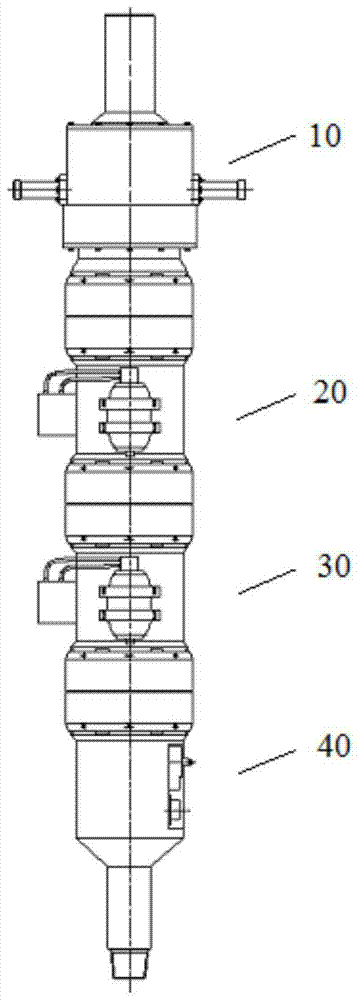

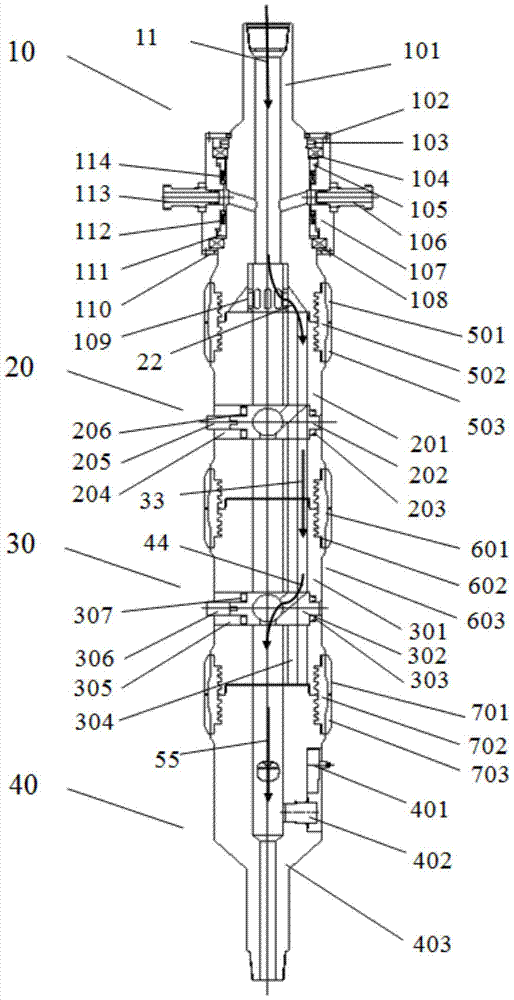

[0037] refer to figure 1 , the overall structure of the device of the present invention is that, from top to bottom, it includes a rotating assembly 10, an upper rubber plug release assembly 20, a lower rubber plug release assembly 30, and an indicator assembly 40 connected in sequence, and each assembly is sequentially connected by The components are sealed; in addition, the cylinder and accumulator ( figure 1 not shown), the cylinder is used to rotate the rotary valve A202 in the upper rubber plug release assembly 20 and the rotary valve B302 in the lower rubber plug release assembly 30, and the accumulator is used to provide power (high pressure gas) to the cylinder.

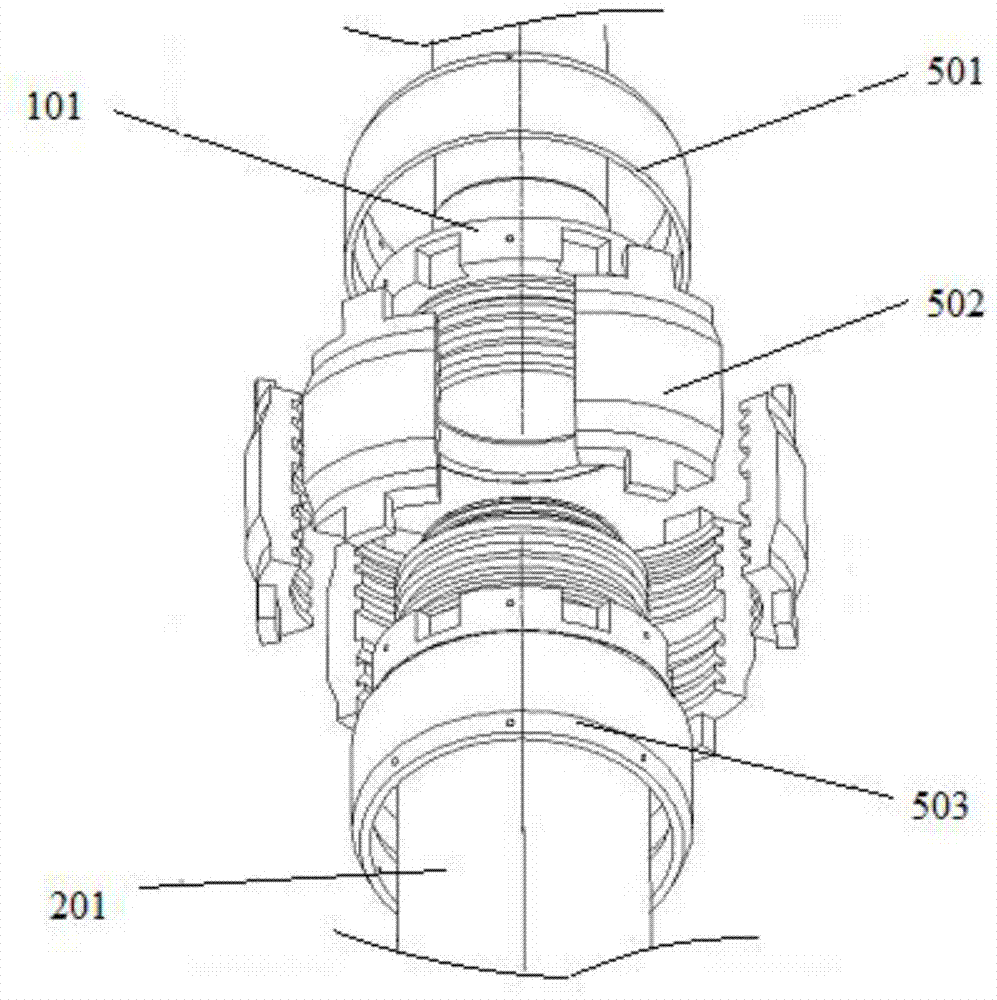

[0038] refer to figure 2 The structure of the rotating assembly 10 is to include an upper joint 101 with a central through hole, the upper joint 101 is used as the main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com