Power cable tensioning device

A technology for power cables and tensioning devices, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, etc., can solve the problems of increased length of transmission cables, inconvenient use, and unfavorable ground lightning weather.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] based on the following Figure 1-7 An embodiment of the present invention is described.

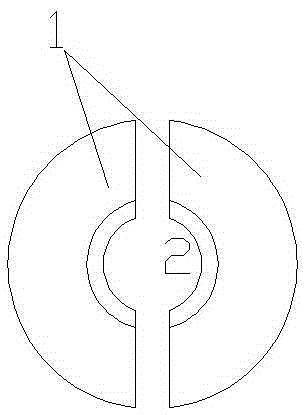

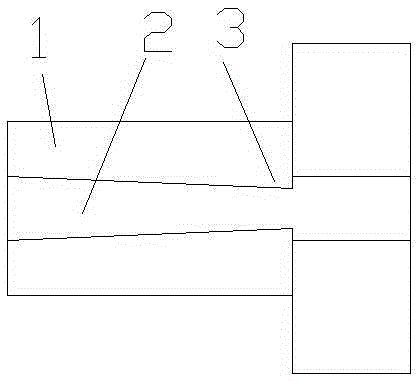

[0021] A power cable tensioning device includes a clamping hoop 1 composed of two halves of clamping units, and the clamping hoop is internally arranged in a channel 2 for cables to pass through.

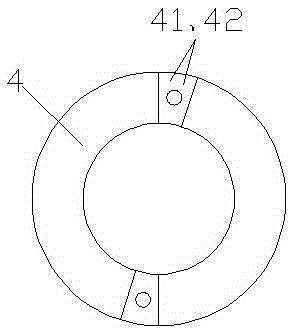

[0022] The inner side of the clamp channel 2 is provided with a boss 3 for clamping the power cable; the outside of the clamp 1 is provided with an external thread, and a clamp nut 4 is provided in cooperation with the outer wall of the clamp. The nut 4 is composed of two half-rings, wherein each side of the half-ring is respectively provided with a protruding head 41 and a groove 42, and the protruding head fits into the groove.

[0023] A hanging hole is provided on the outside of each half ring, and a pull rope 5 is correspondingly provided on the hanging hole; a support 6 is also included, and the bottom of the support 6 is hinged on the base 7, and the upper end both sides of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com