Pull-down device of computerized flat knitting machine

A computerized flat knitting machine and pulling technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of complex rake roller structure, complicated technical operation, high manufacturing cost, etc., and achieve the convenience of full-form weaving and sufficient pulling force , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

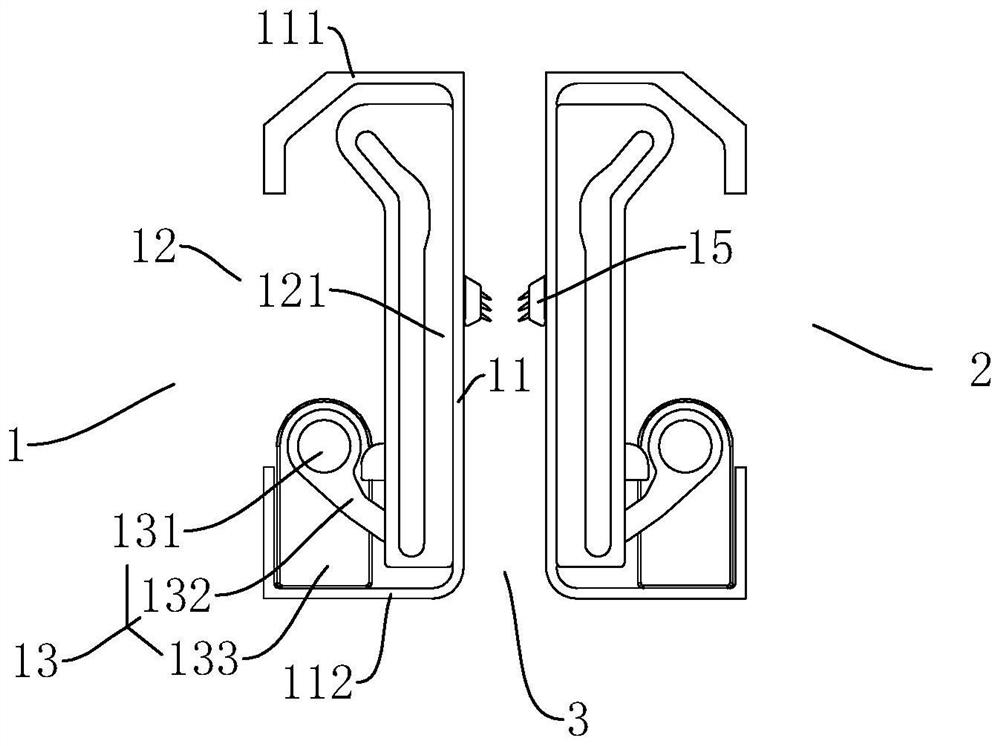

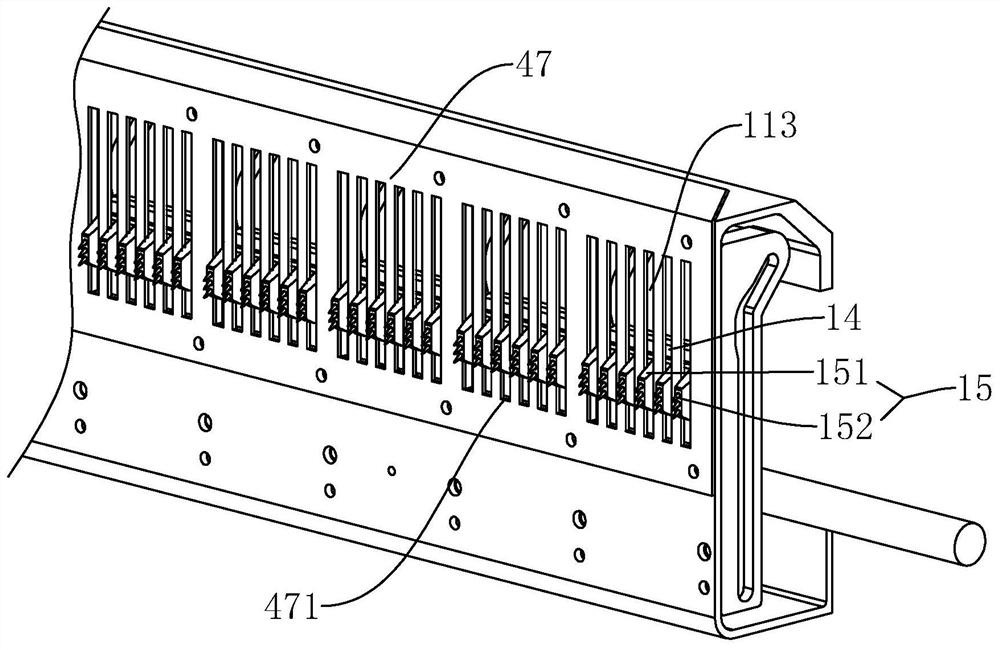

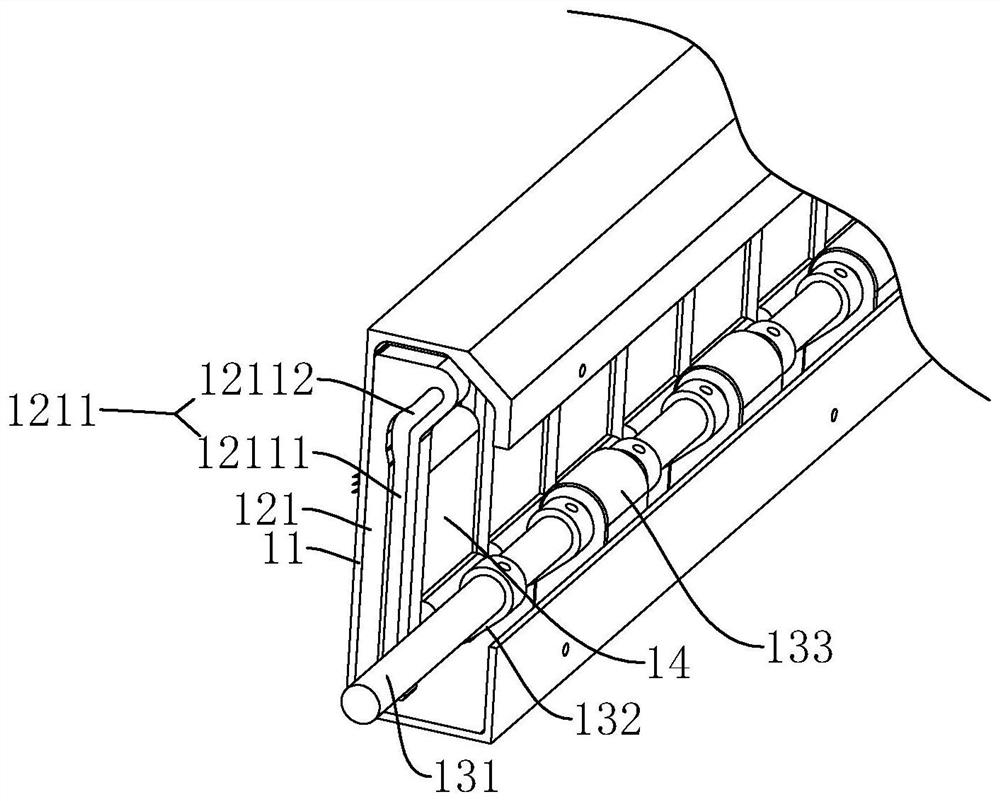

[0032] combine Figure 1 to Figure 7 The pull-down device of the computerized flat knitting machine of the present invention is further described.

[0033] A pull-down device for a computerized flat knitting machine, comprising a left pulling mechanism 1 and a right pulling mechanism 2, the left pulling mechanism 1 and the right pulling mechanism 2 are arranged symmetrically and form a pulling channel 3 for fabrics to pass through. It is characterized in that: the left pulling mechanism 1 and the right pulling mechanism 2 both include a plate frame 11 , a guide assembly 12 , a pulling rake 14 and a driving assembly 13 .

[0034] The plate frame 11 is a strip-shaped structure, on which there are a plurality of windows 113 arranged along the length direction of the plate frame 11, and an upper shielding plate 111 and a lower mounting plate 112 are respectively formed on the upper and lower sides of the back of the plate frame 11; It should be noted that the opposite side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com