Patents

Literature

38results about How to "Pull to achieve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sewage sludge advanced treatment method

InactiveCN104098242AAchieve dryingDoes not increase throughputSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningWaste heat recovery unitPlate heat exchanger

The invention discloses a sewage sludge advanced treatment method which is based on a sewage sludge advanced treatment device. The sewage sludge advanced treatment device comprises a sludge freezing container, a freeze drying energy circulating system and a waste heat recovery device. The freeze drying energy circulating system comprises a compressor, an evaporator, a condenser and a first heat exchanger arranged in the sludge freezing container. The air outlet end of the compressor is connected with the condenser, the condenser is connected with the evaporator through a throttling element, and the evaporator is connected with the air inlet end of the compressor through the first heat exchanger. The waste heat recovery device comprises a waste heat boiler and a heat conduction oil pipe arranged in the waste heat boiler, the heat conduction oil pipe is connected with a second heat exchanger, oil conduction oil enters the second heat exchanger to transfer heat to air, and the air heated is respectively conveyed to a drying device and the sludge freezing container to be used for sludge drying and unfreezing. According to the sewage sludge advanced treatment method, the sludge treatment amount is not increased in the treatment process, and recycling of working medium energy improves sludge freezing efficiency and heat utilization rate.

Owner:CHINA JILIANG UNIV

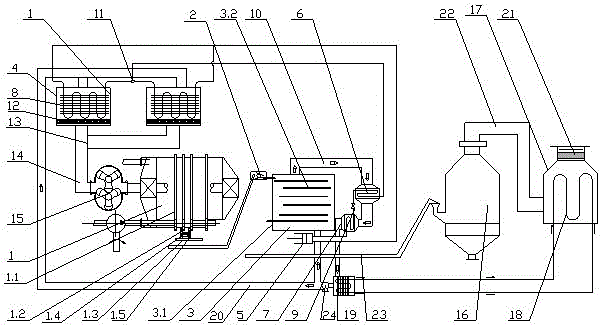

Sewage sludge advanced treatment device

InactiveCN104098241AAchieve dryingRealize step-by-step processingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningCombustionFreeze-drying

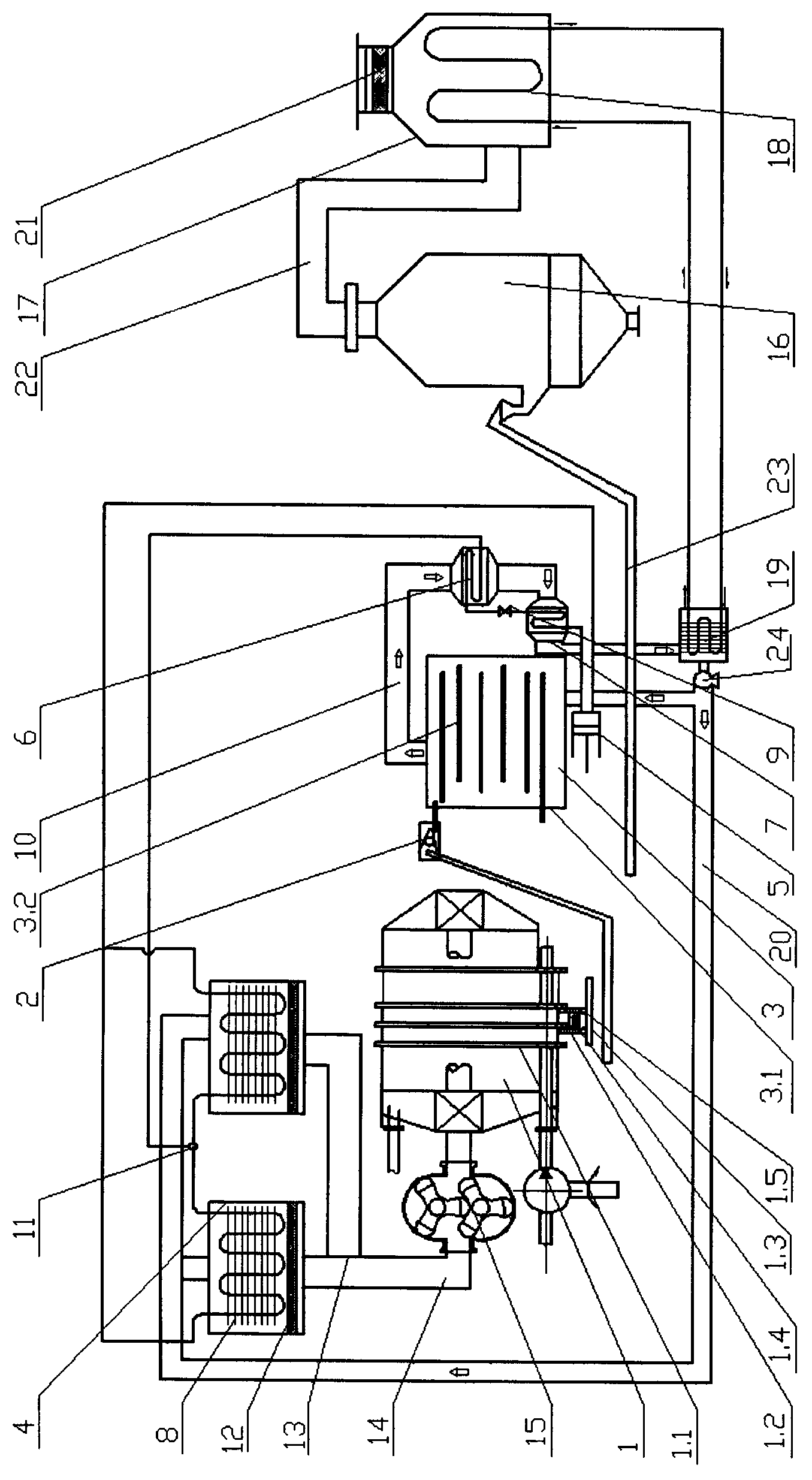

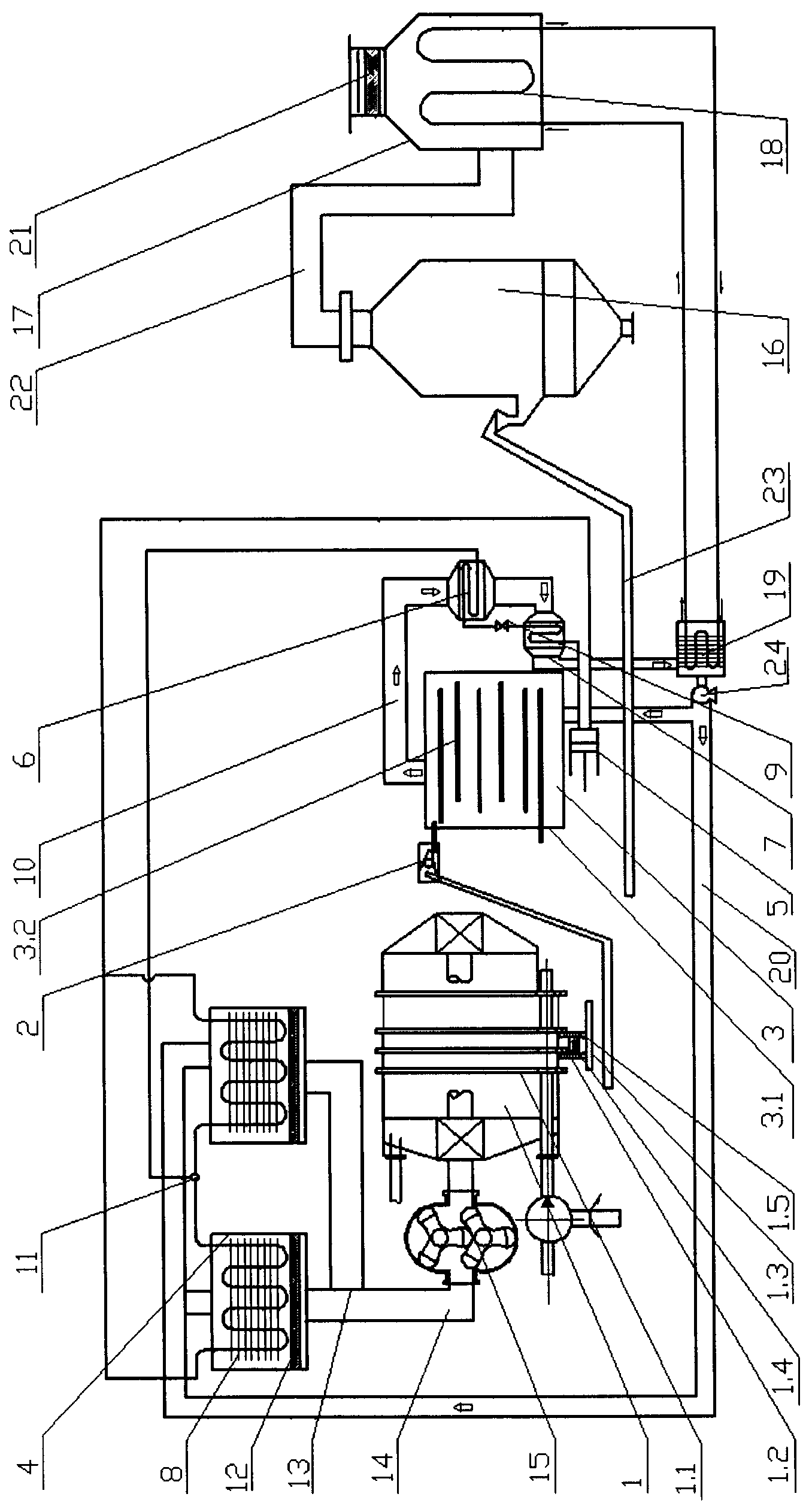

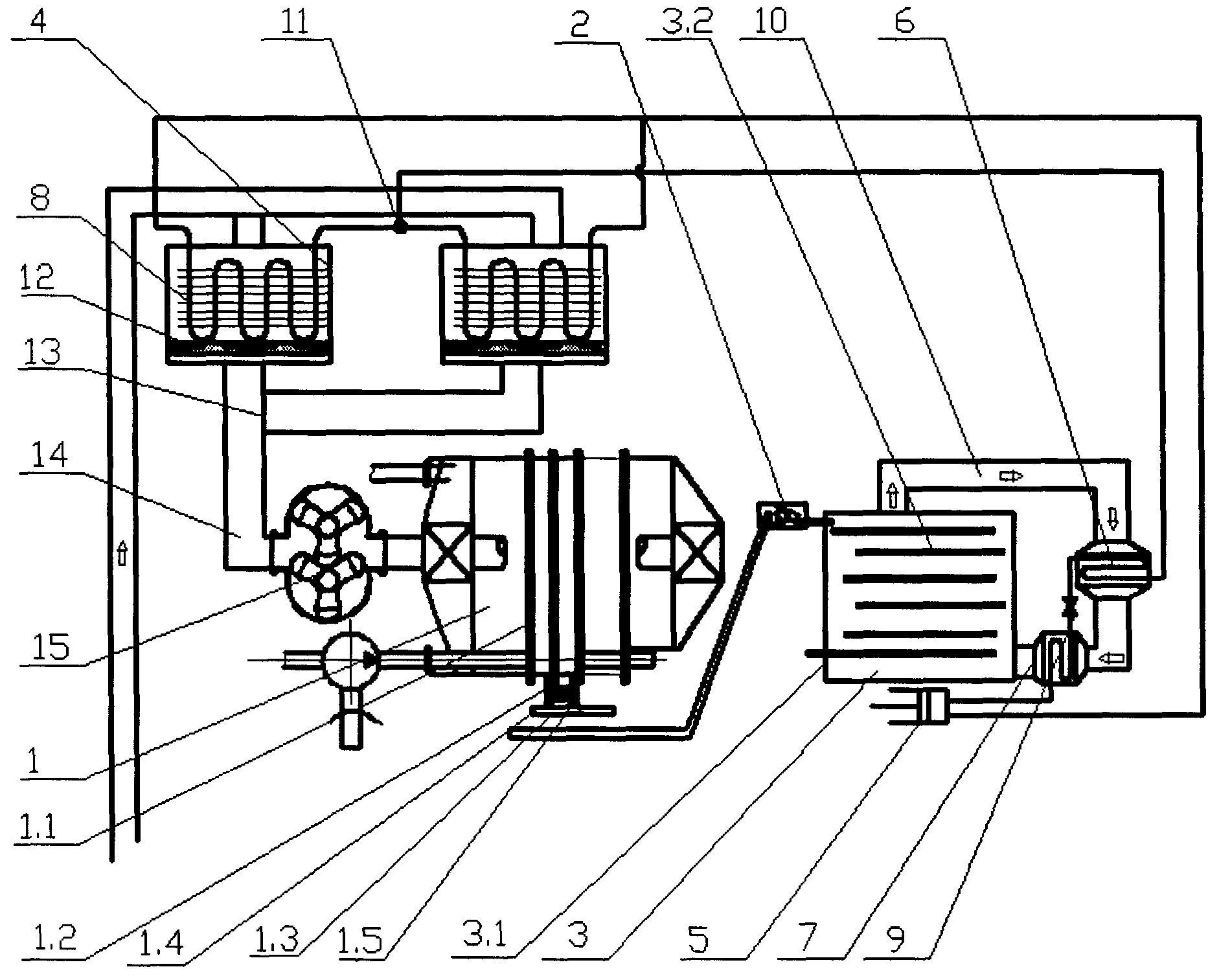

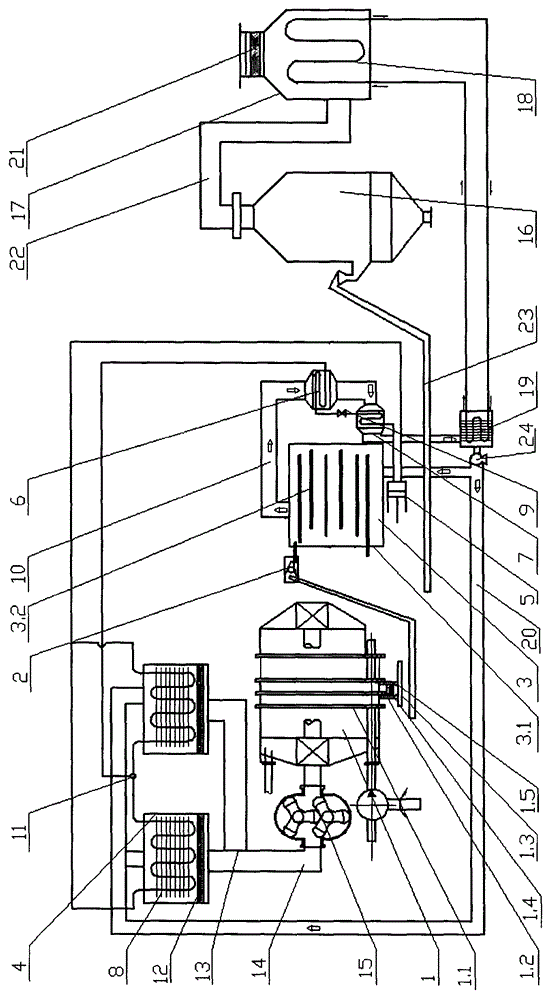

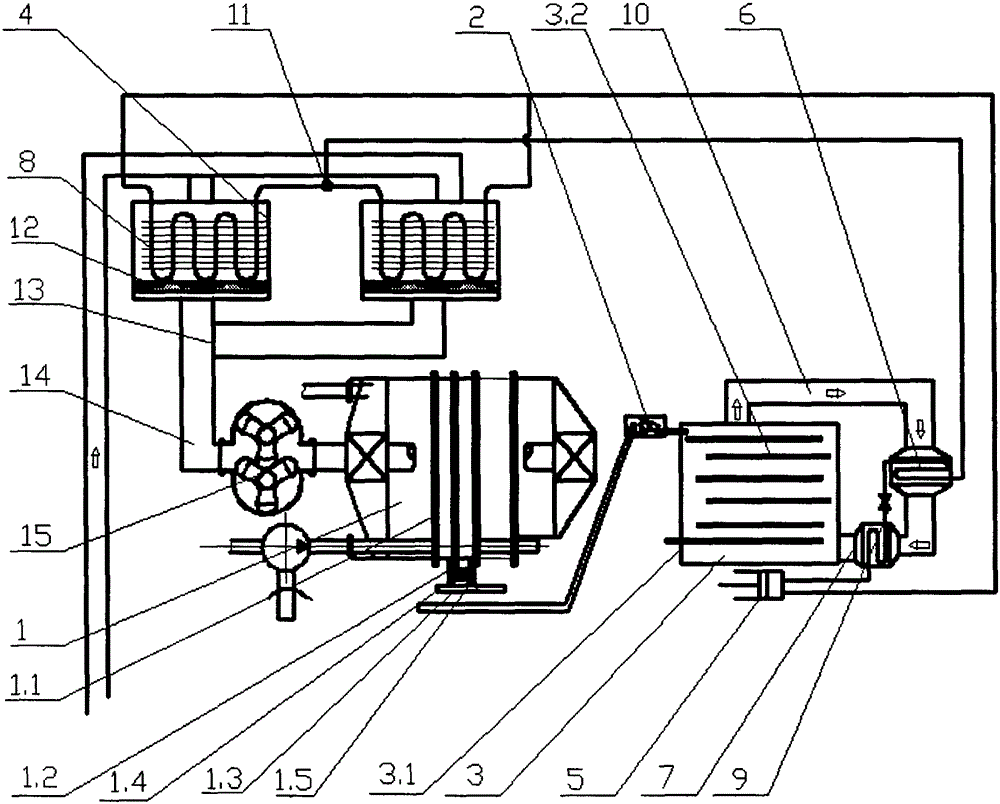

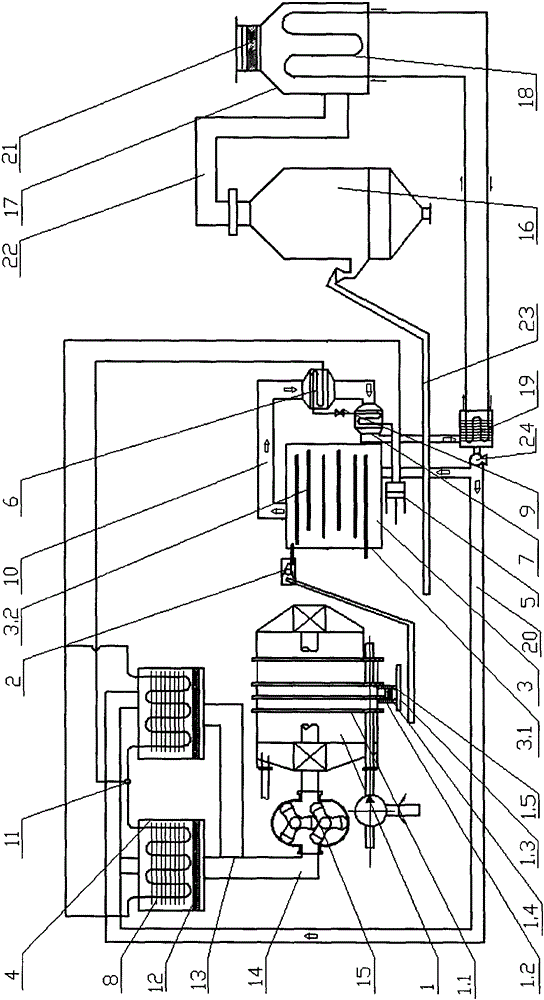

The invention discloses a sewage sludge advanced treatment device which comprises a crushing device, a drying device, a combustion device and a waste heat boiler. The sewage sludge advanced treatment device further comprises a sludge freezing container and a freeze drying energy circulating system. The freeze drying energy circulating system comprises a compressor, an evaporator, a condenser and a first heat exchanger arranged in the sludge freezing container. The air outlet end of the compressor is connected with the condenser, the evaporator is connected with the air inlet end of the compressor through the first heat exchanger, the condenser is communicated with the bottom of the drying device through a gas pipeline, and the evaporator is communicated with the top of the drying device through a gas pipeline. A heat conduction oil pipe is arranged in the waste heat boiler and performs heat transfer with air to heat the air, and the air heated is respectively conveyed to the drying device and the sludge freezing container to be used for sludge drying and unfreezing. According to the sewage sludge advanced treatment device, chemical agents do not need to be added, the sludge treatment amount is not increased, and sludge freezing efficiency and the heat utilization rate are improved through recycling of working medium energy and heat of sludge.

Owner:CHINA JILIANG UNIV

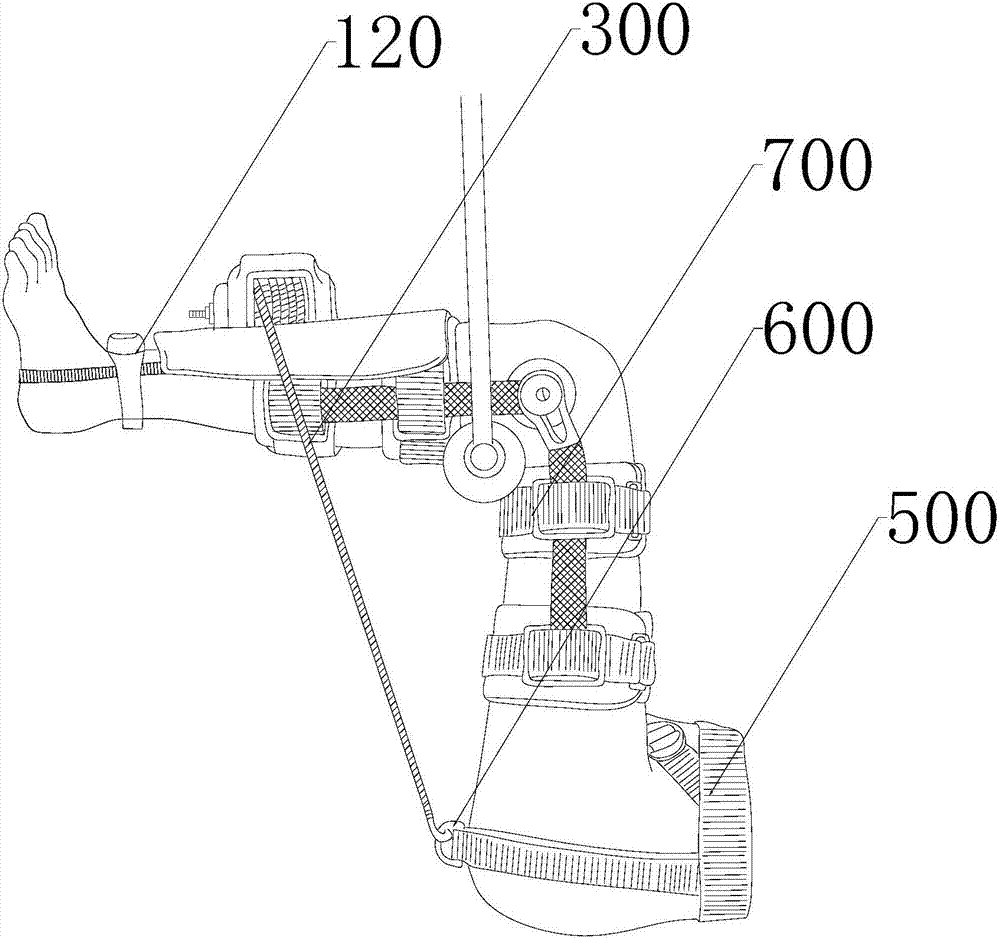

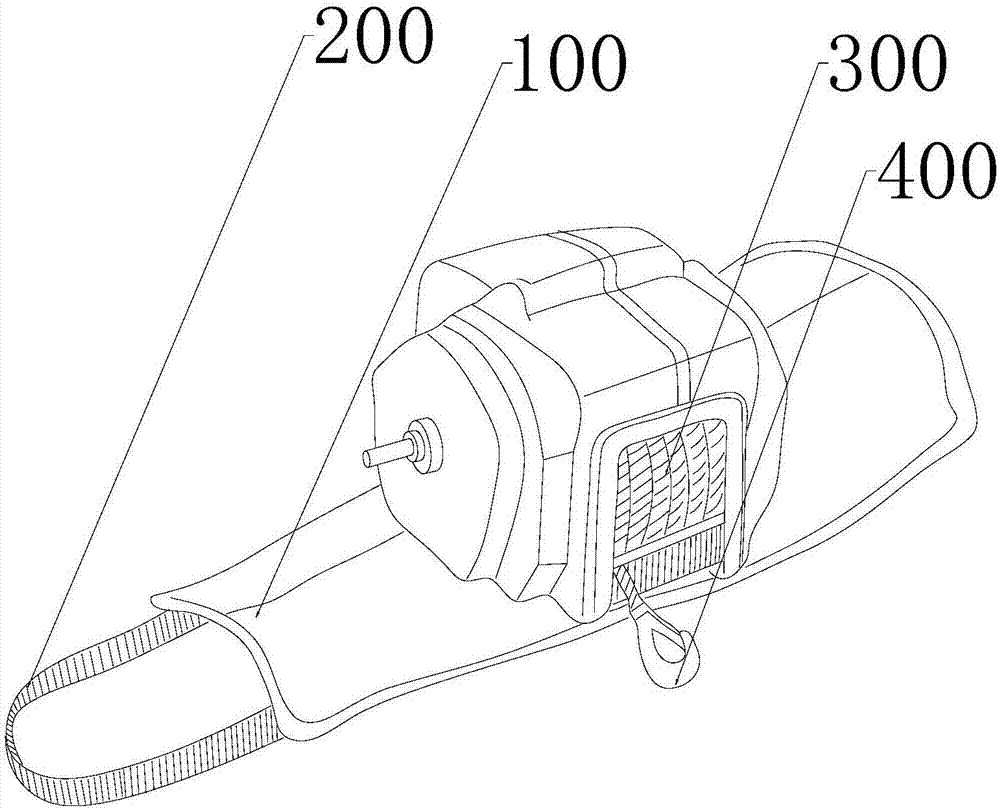

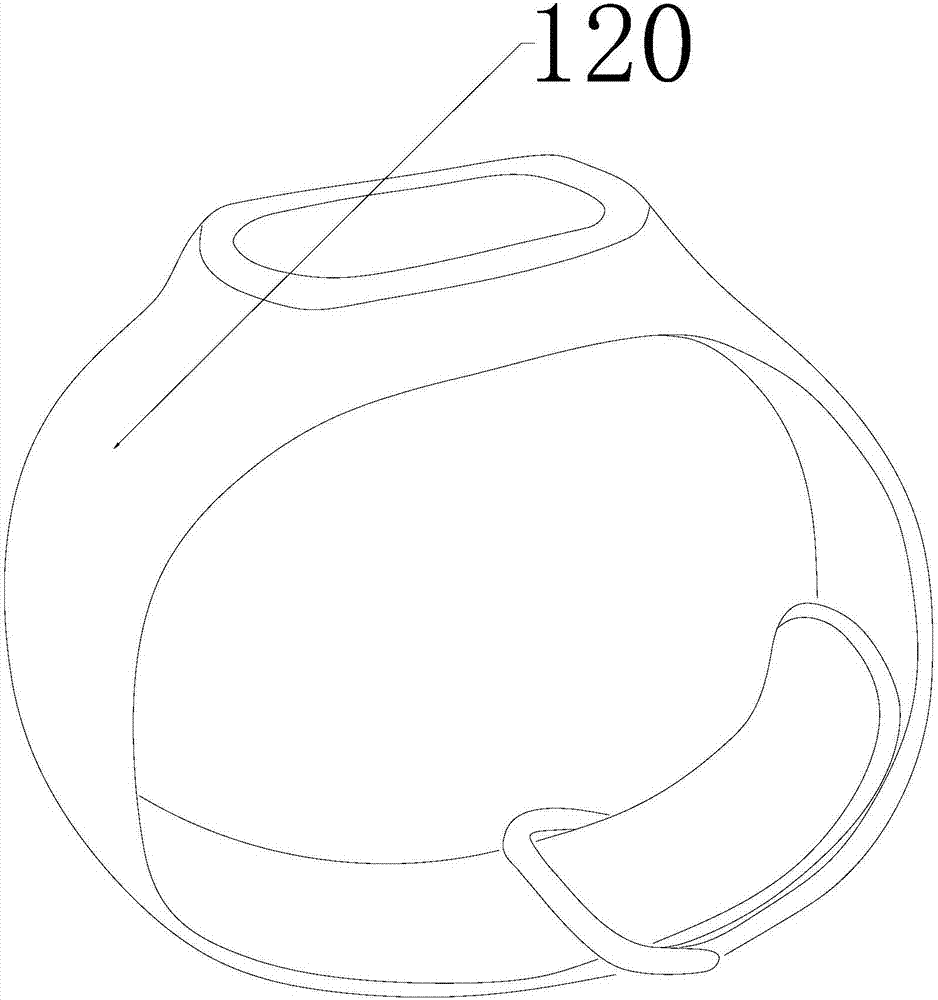

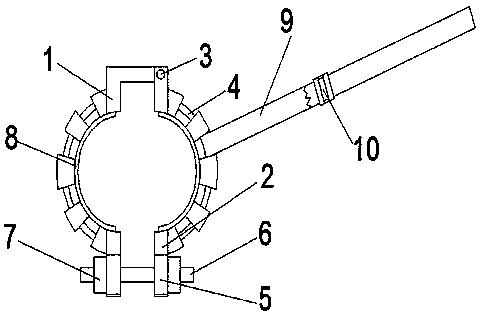

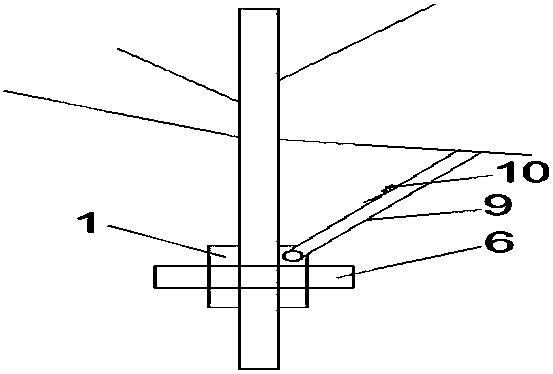

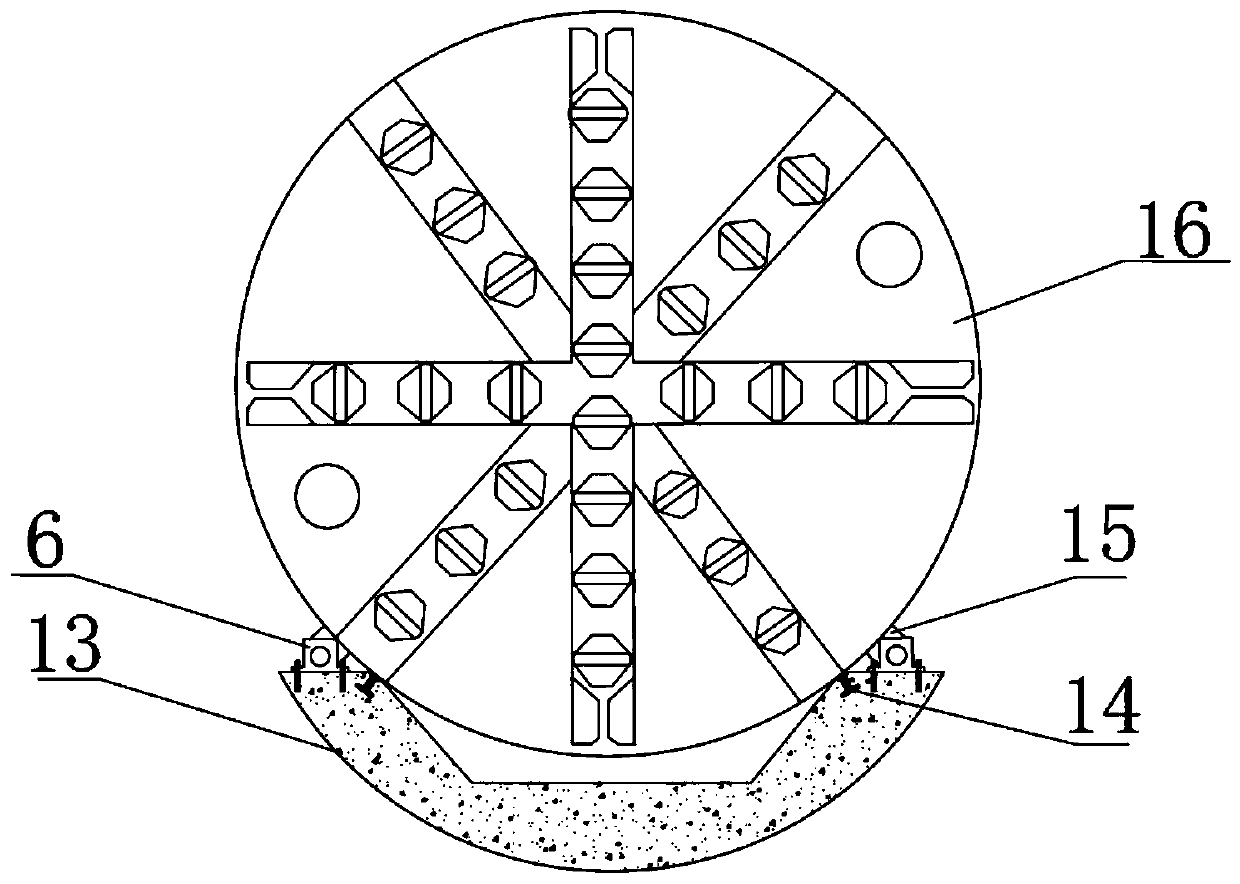

Knee joint rehabilitation device

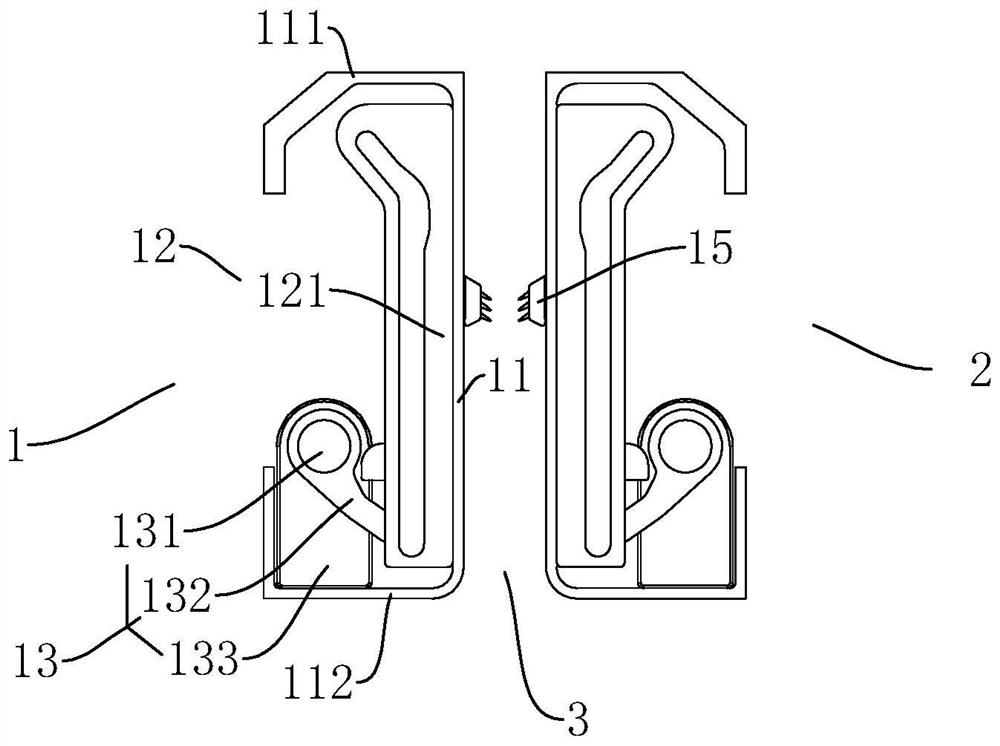

PendingCN107174484APull to achievePrecisely control the angle of bucklingDiagnosticsChiropractic devicesPhysical medicine and rehabilitationKnee Joint

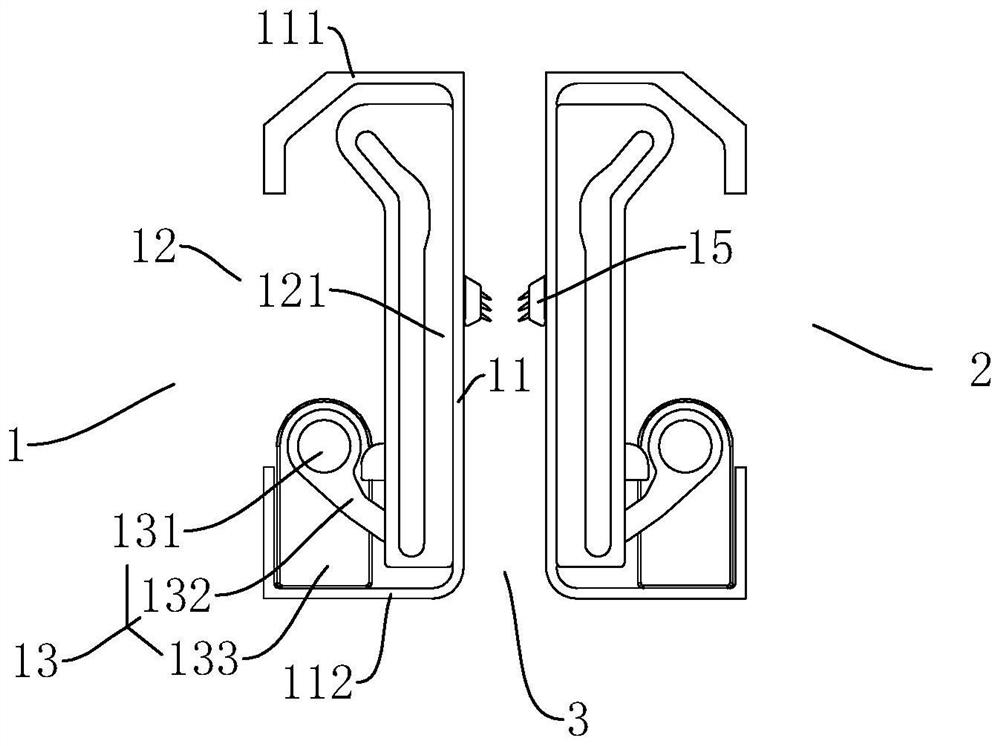

The invention provides a knee joint rehabilitation device, relating to the technical field of knee joint rehabilitation. The knee joint rehabilitation device comprises a traction device, an angle measurement device, a traction fixing device and a suspension device, wherein the traction device is mounted on an injured limb, and the angle measurement device is used for measuring a bending angle of the injured limb; the suspension device is used for suspending the injured limb; and the traction fixing device is fixed on a human body, and a traction rope connected with the traction fixing device is arranged on the traction device. According to the knee joint rehabilitation device, the traction device is connected with the traction fixing device, the injured limb of a patient is suspended on the suspending device, and the unreeling length of the traction rope is changed by the traction device, so that the traction of a knee joint of the patient can be realized; and meanwhile, the bending angle of the knee joint of the patient can be measured by the angle measurement device, and the flexibility of the knee joint can be assisted to be rehabilitated and exercised by accurately controlling the bending angle of the knee joint.

Owner:广州辛群科技有限公司

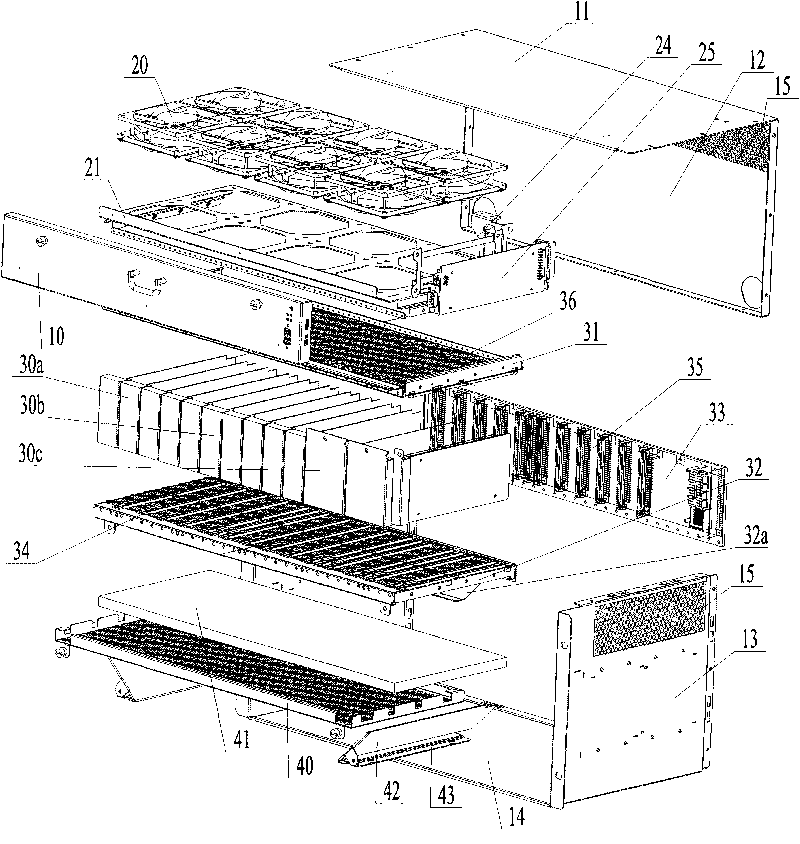

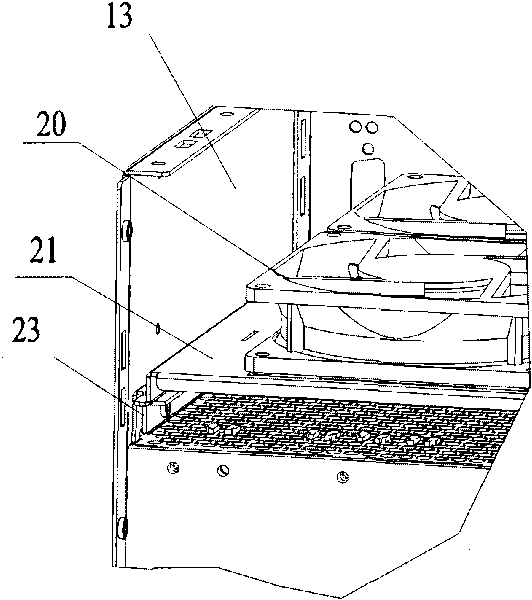

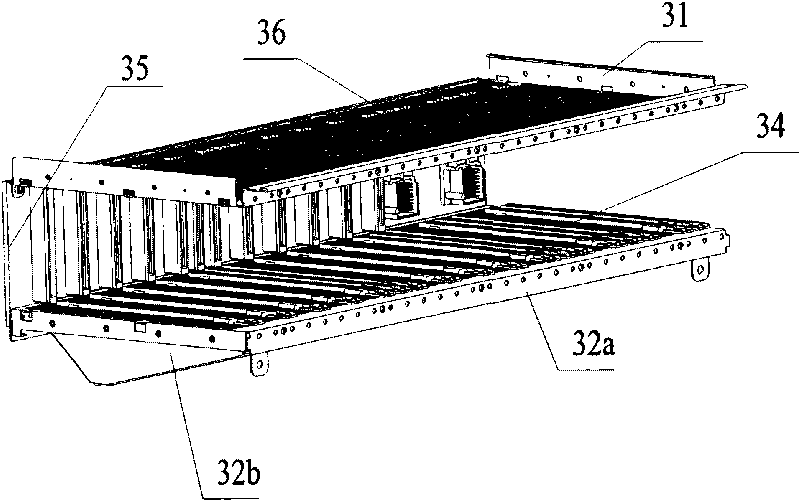

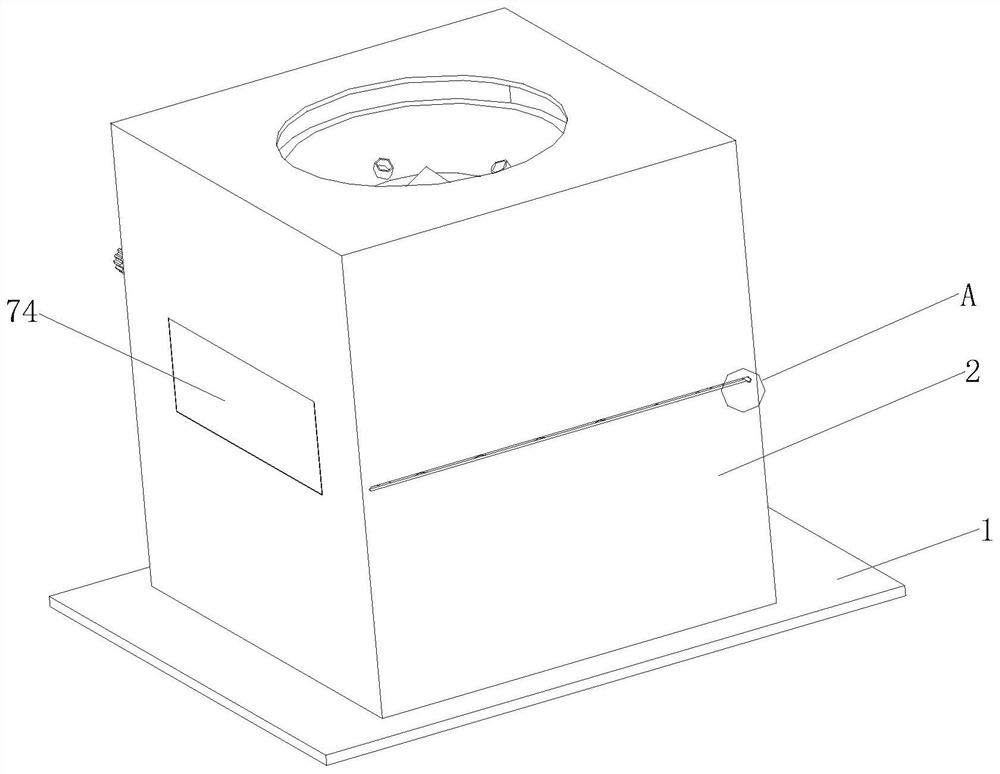

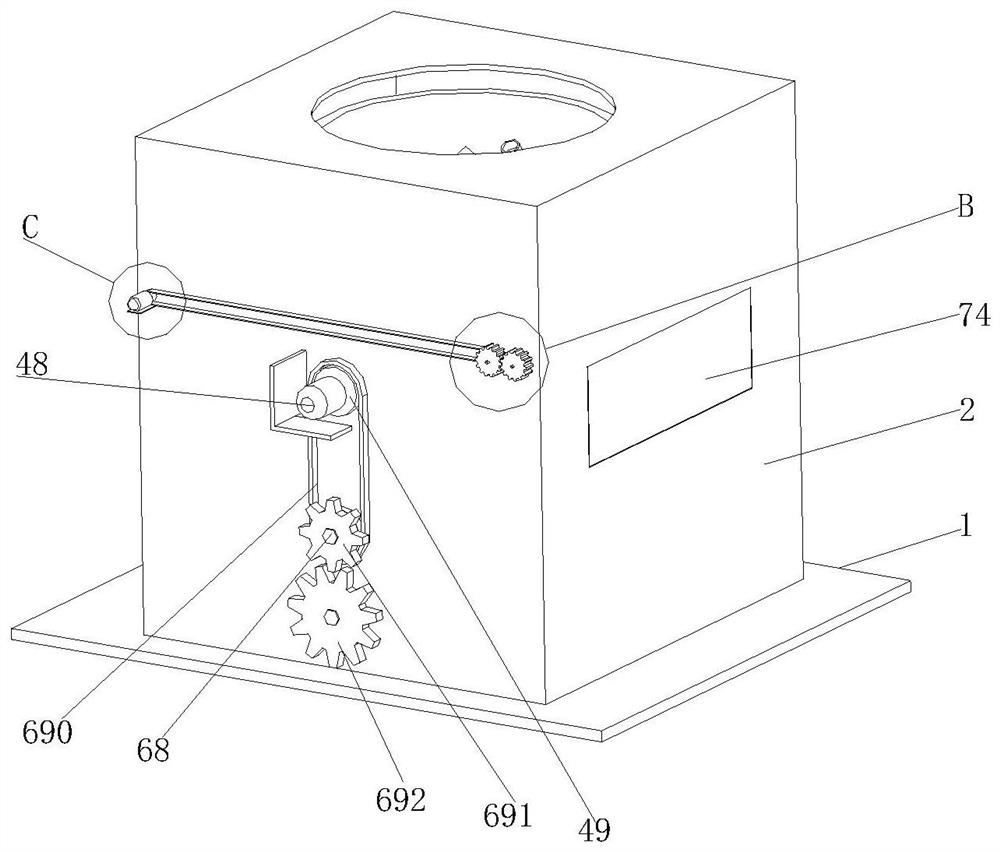

Micro TCA exchange platform

InactiveCN101753317AHighly integratedHigh integration, can provide higher system density than ATCAData switching detailsDigital processing power distributionRear quarterComputer module

The invention discloses a Micro TCA exchange platform, comprising a chassis consisting of a top plate, a front panel, a back panel, two side plates and a bottom plate. The upper part of the chassis is provided with a fan module and an alarming monitoring module, the middle part of the chassis is provided with an AMC (automatic message counting) module, a switch fabric card and a power supply module, and the lower part of the chassis is provided with a dustproof filtering device. The invention provides the Micro TCA exchange platform which has the advantages of high flexibility, very high integrated level, high expansion elasticity and management function, no need of a support plate, small dimension and low cost.

Owner:EVOC INTELLIGENT TECH

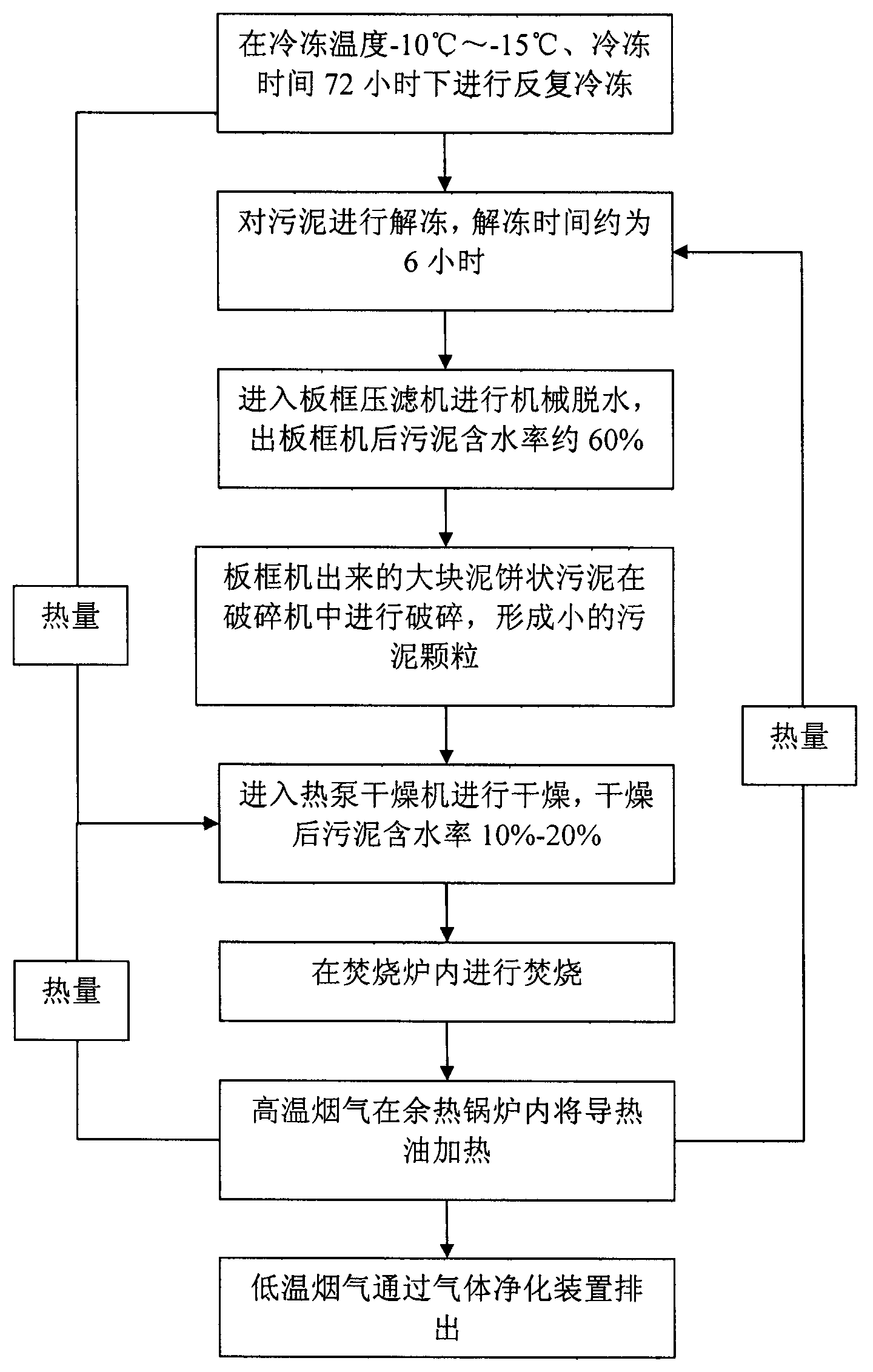

Sewage sludge treatment method

InactiveCN104098239AAchieve dryingRealize step-by-step processingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFreeze-dryingSewage

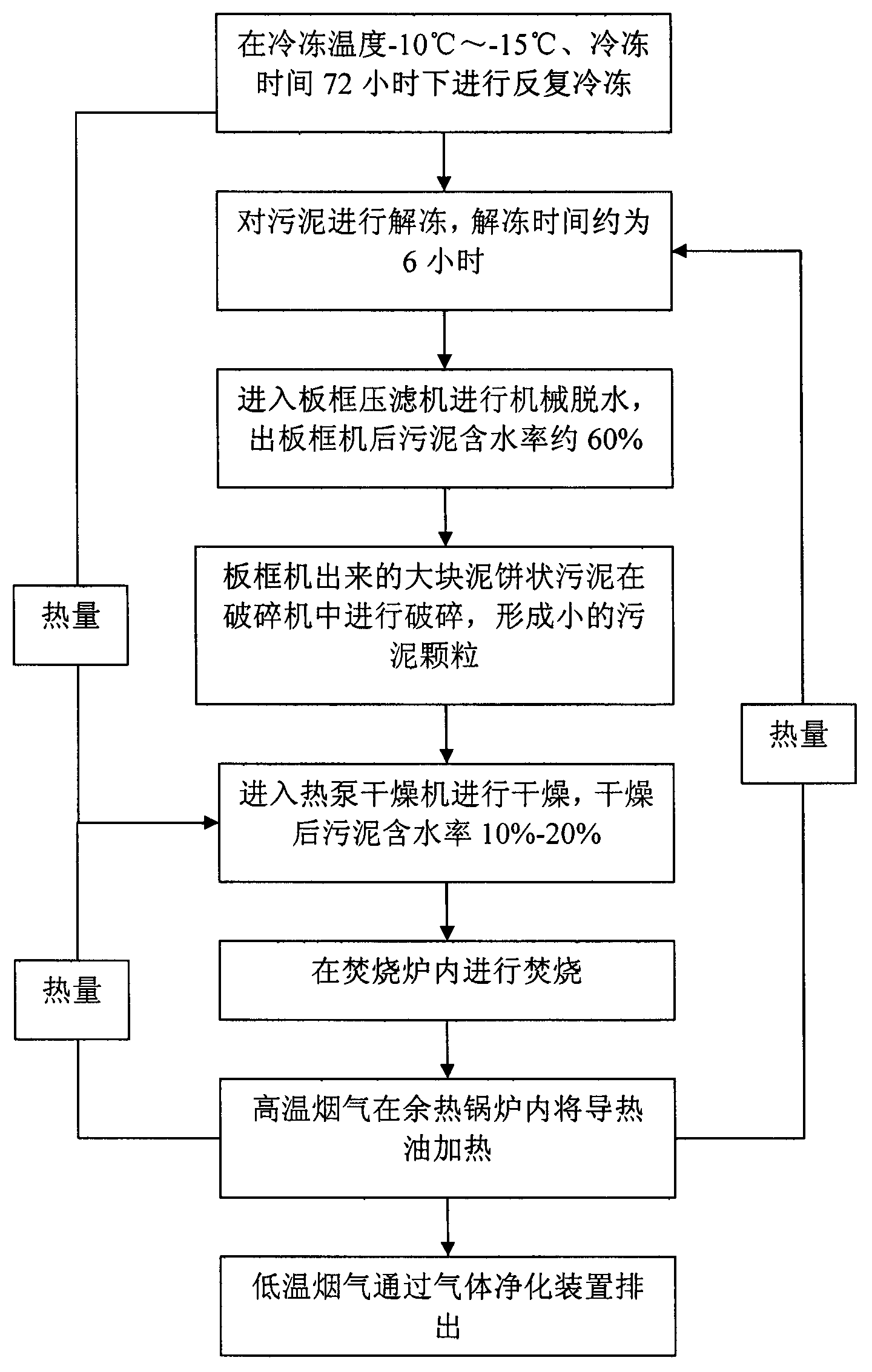

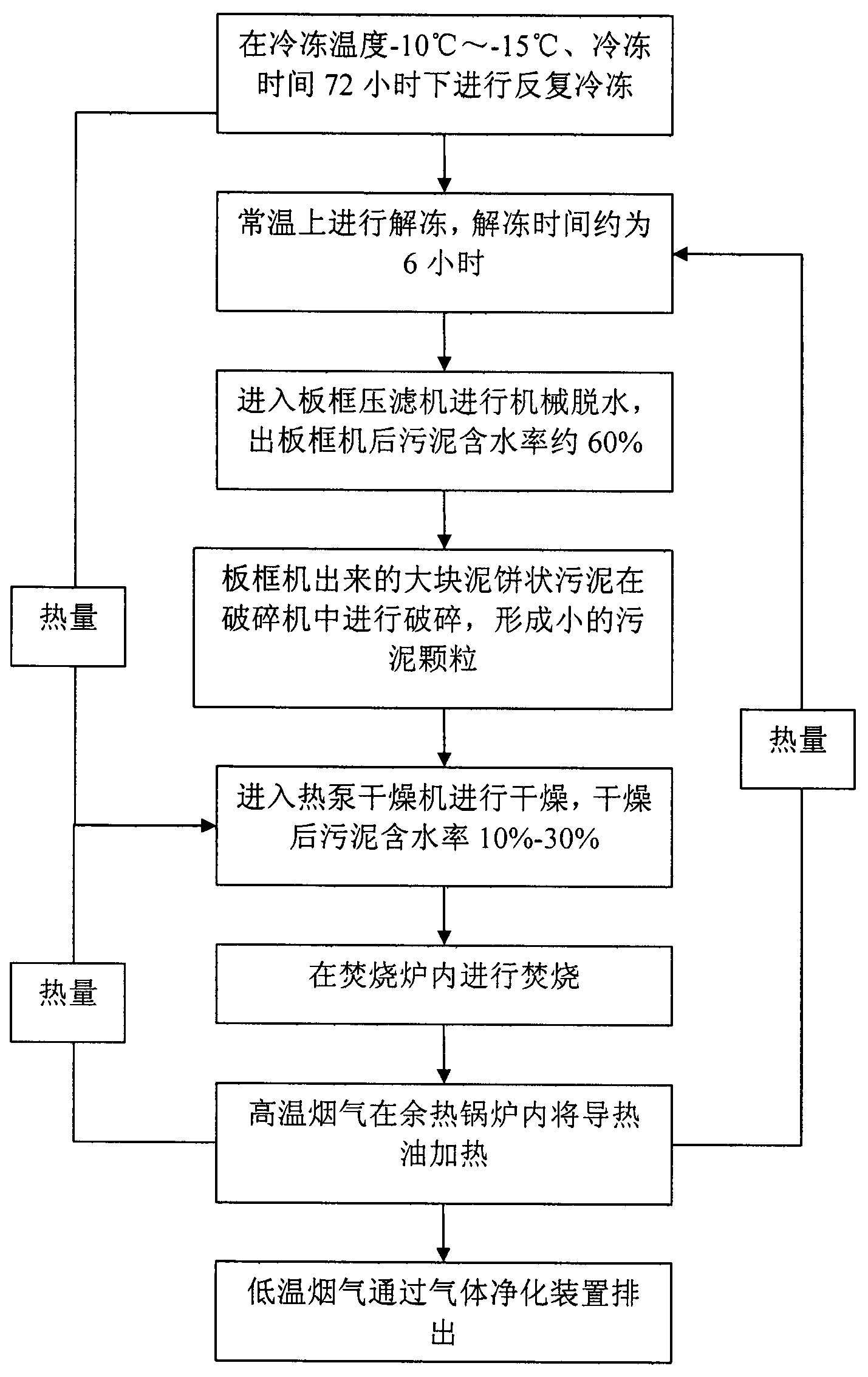

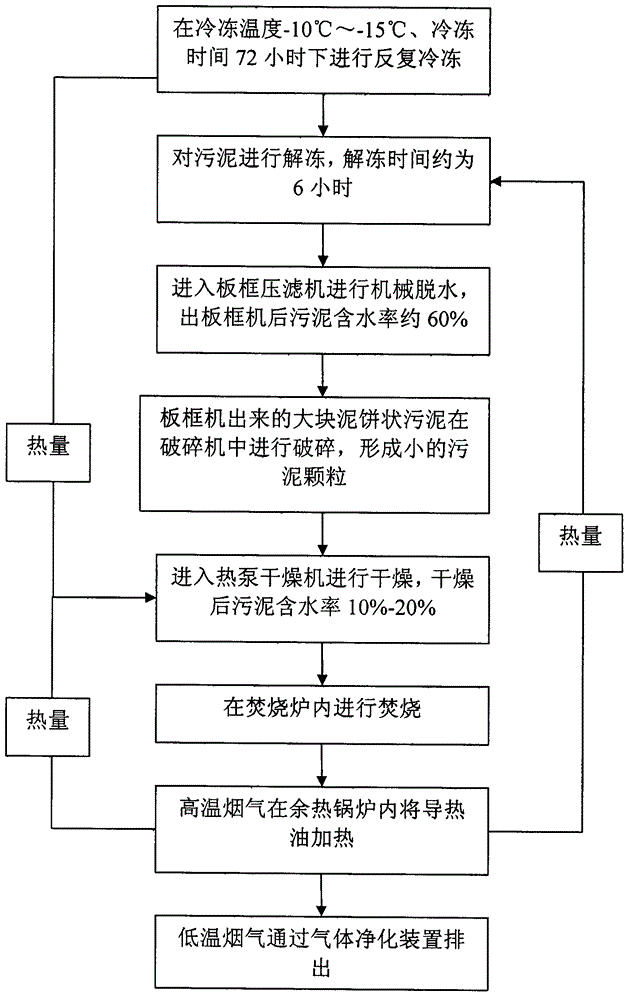

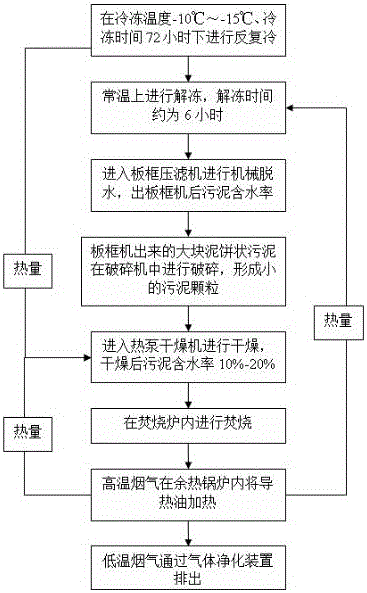

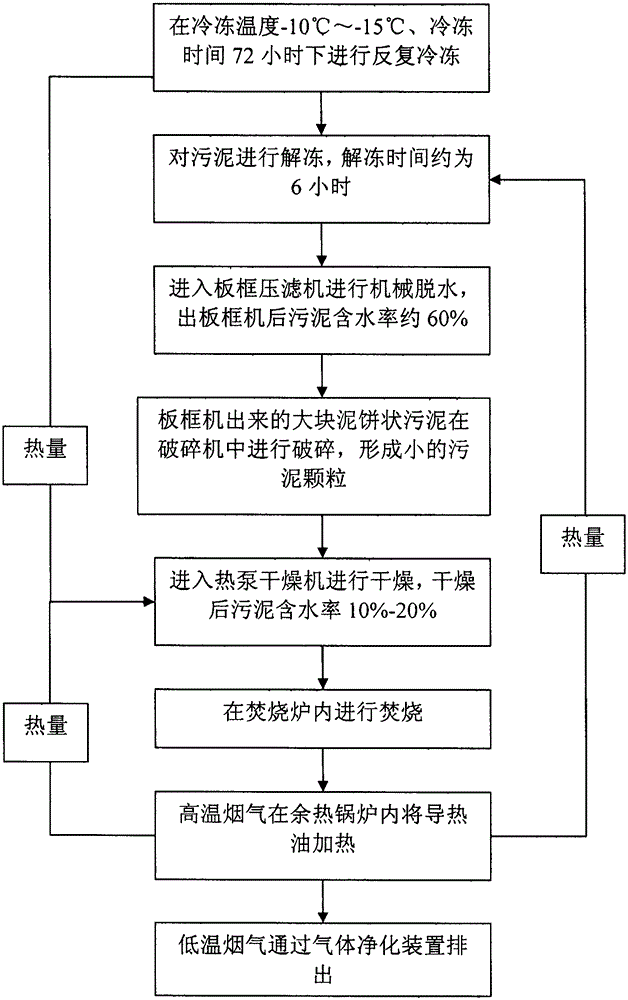

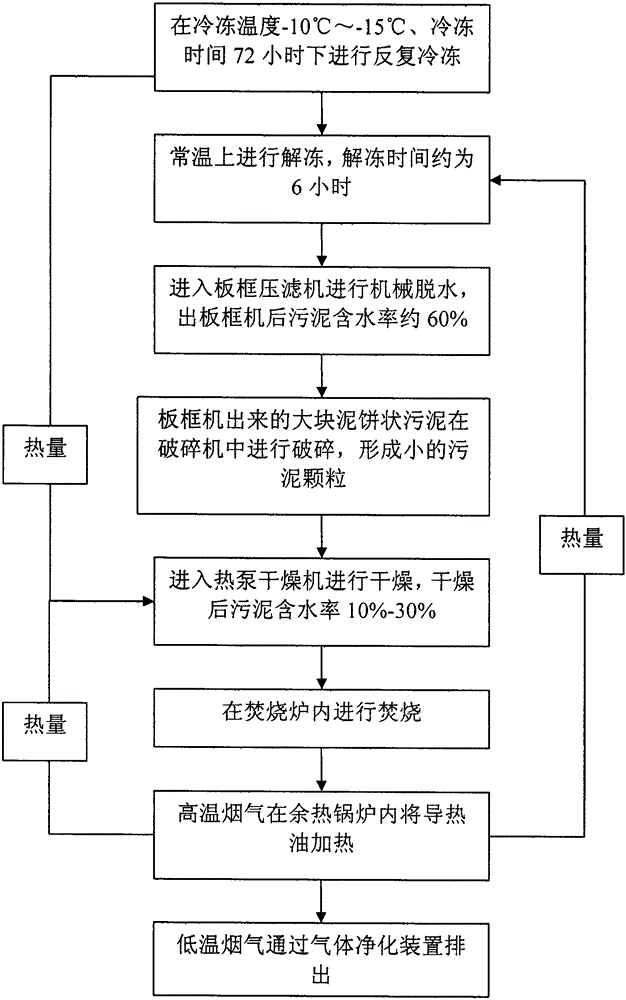

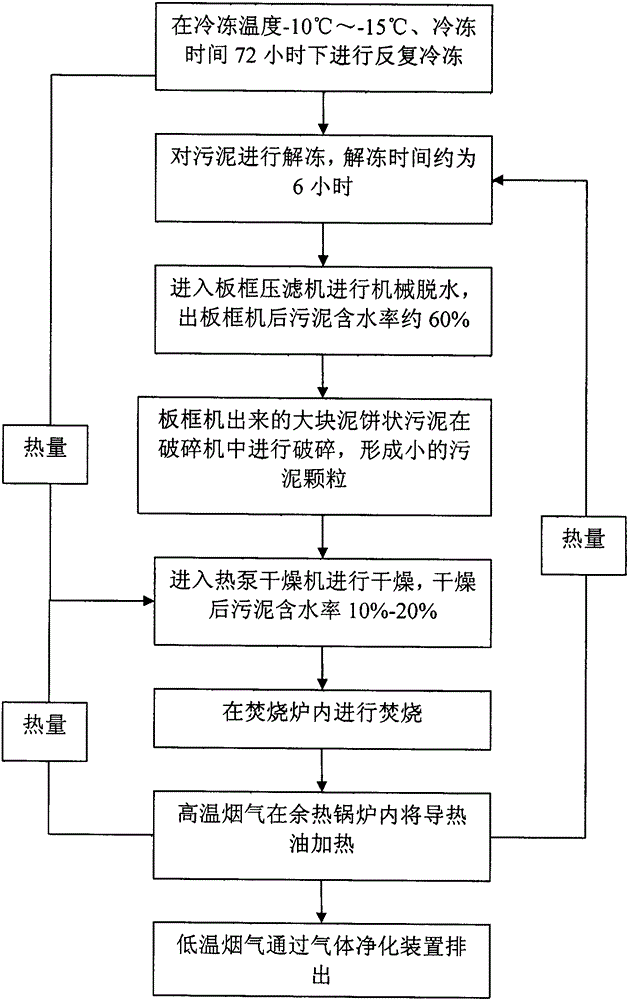

The invention discloses a sewage sludge treatment method. The sewage sludge treatment method comprises a first step of utilizing a freeze drying energy circulating system to continuously freeze sludge in a sludge freezing container, unfreezing the sludge after continuous freezing, and performing freezing and unfreezing repeatedly; a second step of dehydrating the sludge having undergone freezing and unfreezing treatment in a filter pressing device, wherein dehydration comprises a filter pressing stage and a squeezing dewatering stage, and enabling the sludge to undergo filter pressing to be chunk mud-cake-shaped sludge low in moisture content; a third step of crushing the chunk mud-cake-shaped sludge in a crushing device and forming small sludge particles; a fourth step of conveying the crushed sludge particles to enter a sludge drying device to be dried, enabling the freeze drying energy circulating system to release heat through a condenser, transferring heat to air, and enabling the hot air to enter the sludge drying device to dry the sludge particles. According to the sewage sludge treatment method, chemical agents do not need to be added to sludge, the sludge treatment amount is not increased in the treatment process, and recycling of working medium energy greatly improves sludge freezing efficiency and heat utilization rate.

Owner:CHINA JILIANG UNIV

Energy-saving type sewage sludge harmless treatment method

InactiveCN104140188AAchieve dryingDoes not increase throughputSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFreeze-dryingSludge

The invention discloses an energy-saving type sewage sludge harmless treatment method. The method includes the following steps of firstly, conducting continuous freezing on sludge through a freeze drying energy circulation system, and unfreezing the sludge after continuous freezing; secondly, conducting dewatering on the sludge, completely processed through freezing and unfreezing, in a filter pressing device, so that sludge with the low moisture content is obtained through filter pressing; thirdly, smashing the sludge in a smashing device; fourthly, conveying smashed sludge particles into a sludge drying device to be dried, dissipating heat through the freeze drying energy circulation system by means of a condenser, and transferring heat to air; fifthly, sending the sludge particles into an incinerator to be incinerated, making generated high-temperature smoke enter a waste heat boiler, making air heated by the condenser enter a second heat exchanger to continue to absorb heat, and unfreezing the sludge and drying the sludge particles through the formed high-temperature air. By means of the method, the sludge processing amount cannot be increased in the treatment process, and due to recycling of working medium energy, the freezing efficiency and the heat utilization rate of the sludge are increased.

Owner:CHINA JILIANG UNIV

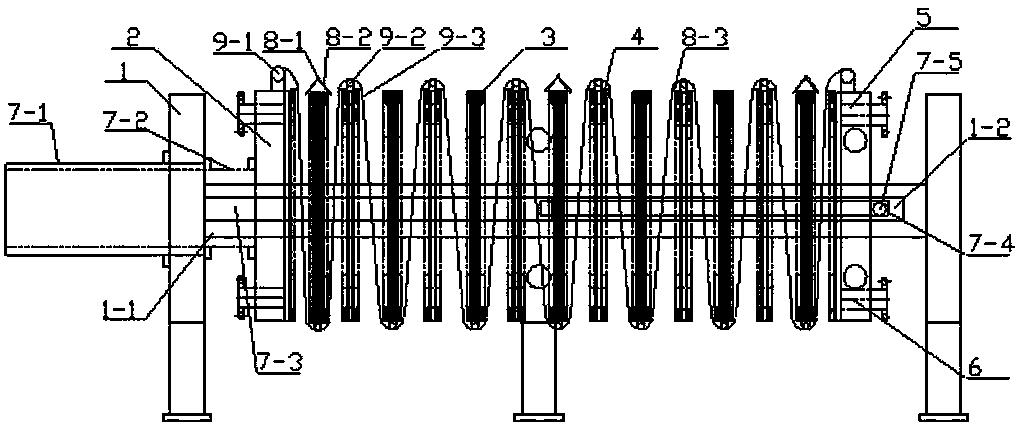

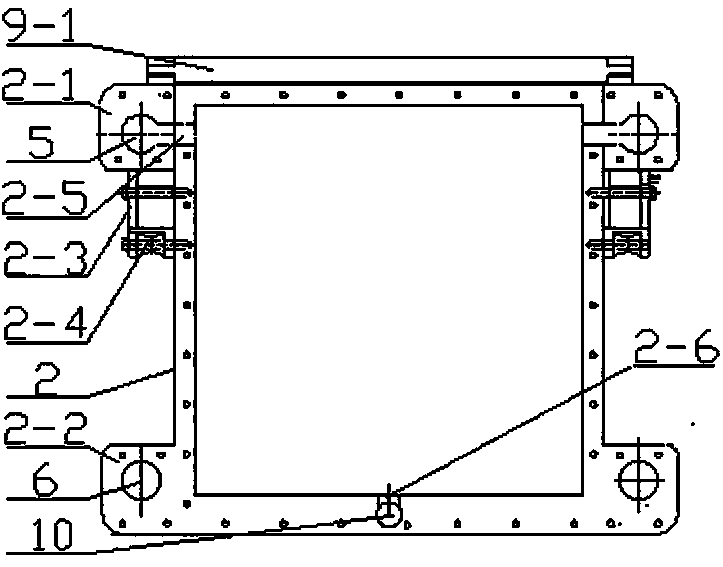

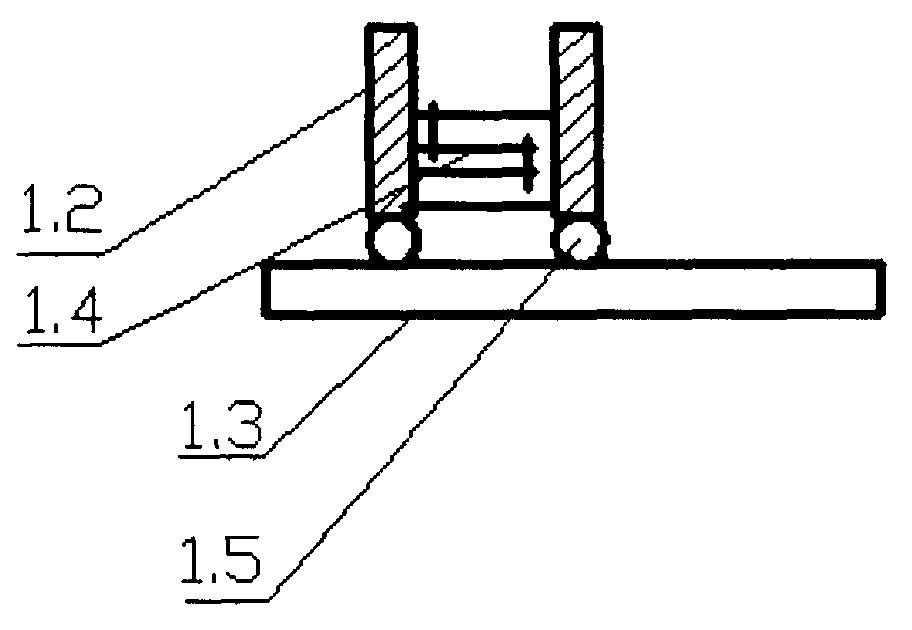

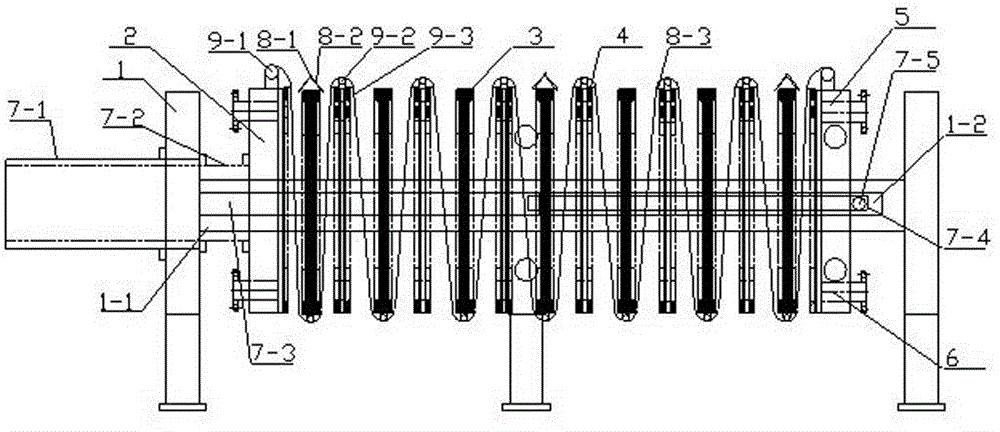

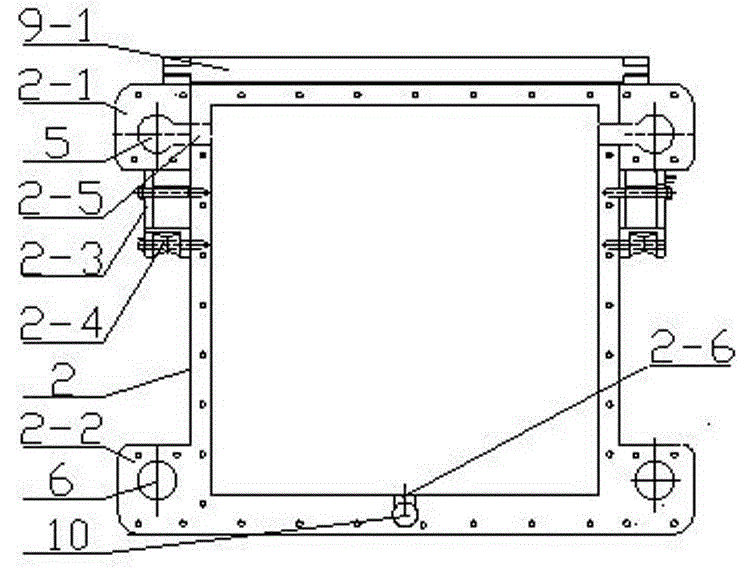

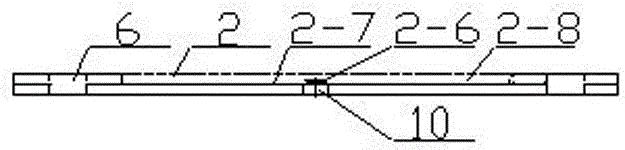

Solid and liquid separator for materials

ActiveCN103657176AImprove stressThe moisture content of solids is reducedFiltration separationPush and pullLocking mechanism

The invention discloses a solid and liquid separator for materials. The solid and liquid separator comprises a frame, press plates, filter plates, a push-and-pull locking mechanism, a filter cloth mechanism, a filter cloth regeneration mechanism and a cleaning mechanism which are arranged on the frame, wherein the press plates and the filter plates are arranged on the frame in a sliding way alternately, and are matched to extrude a material, so that solid and liquid of the material can be separated; the push-and-pull locking mechanism is used for locking, pushing away all the press plates and filter plates, so that solid-liquid separation operation can be performed, or the material can be discharged; the filter cloth mechanism is used for separating solid and liquid of the material when the material is extruded; the filter cloth regeneration mechanism is used for washing to regenerate the filter cloth after the material is discharged; the cleaning mechanism is used for cleaning the material attached to the separator after solid and liquid of the material are separated. The solid and liquid separator has the characteristics of reasonable design, high structure strength, convenience in operation, complete solid and liquid separation, high separation efficiency, convenience in cleaning, long service life, log maintenance frequency, high reliability, strong practicality and the like, and is beneficial for greatly increasing production benefit of enterprises.

Owner:四川宝凯鑫诚环保科技有限公司

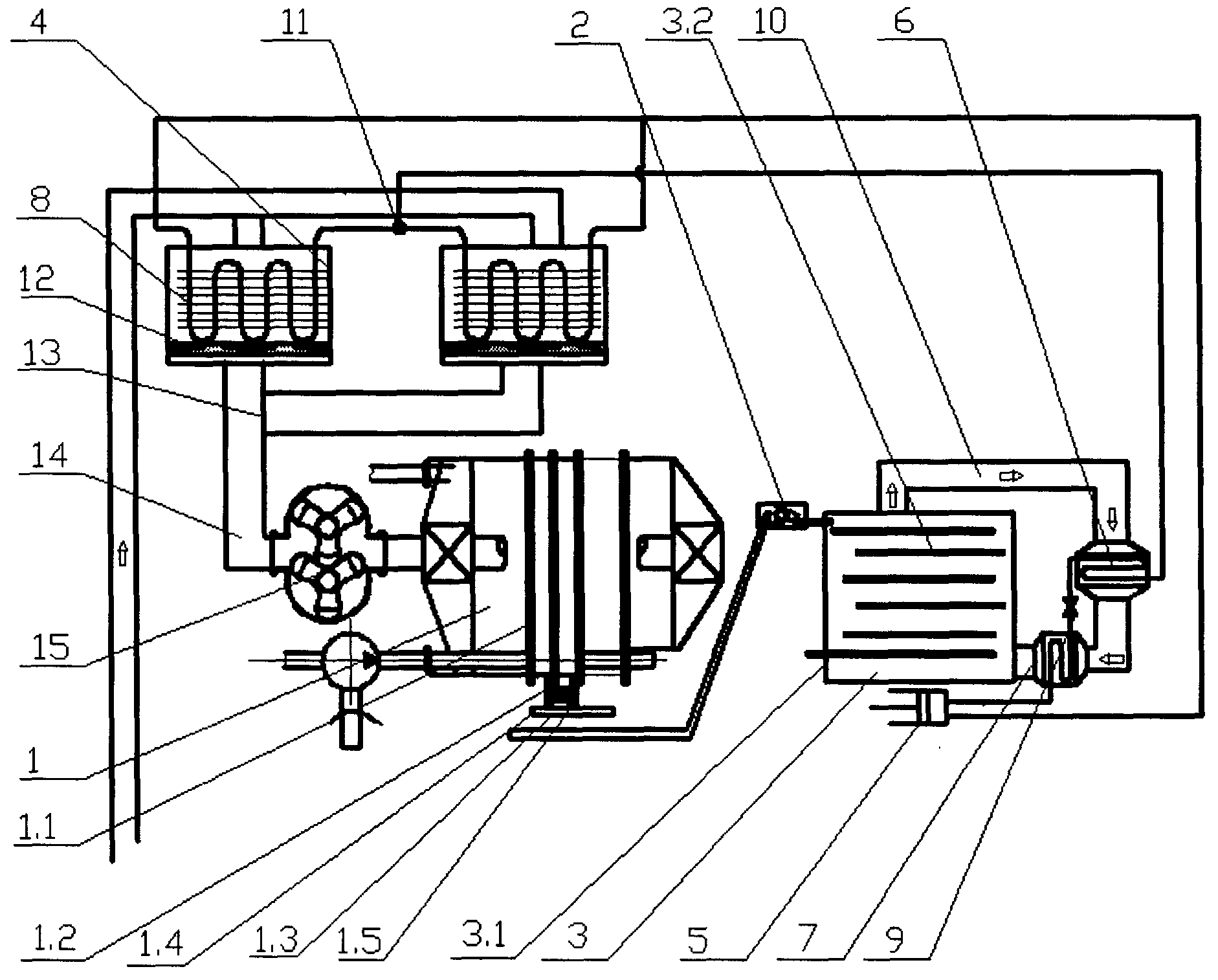

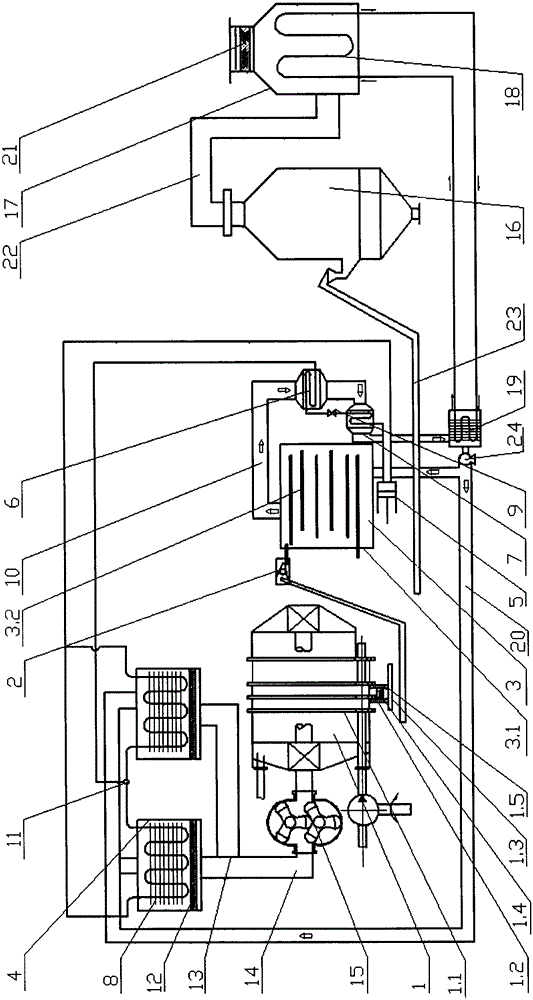

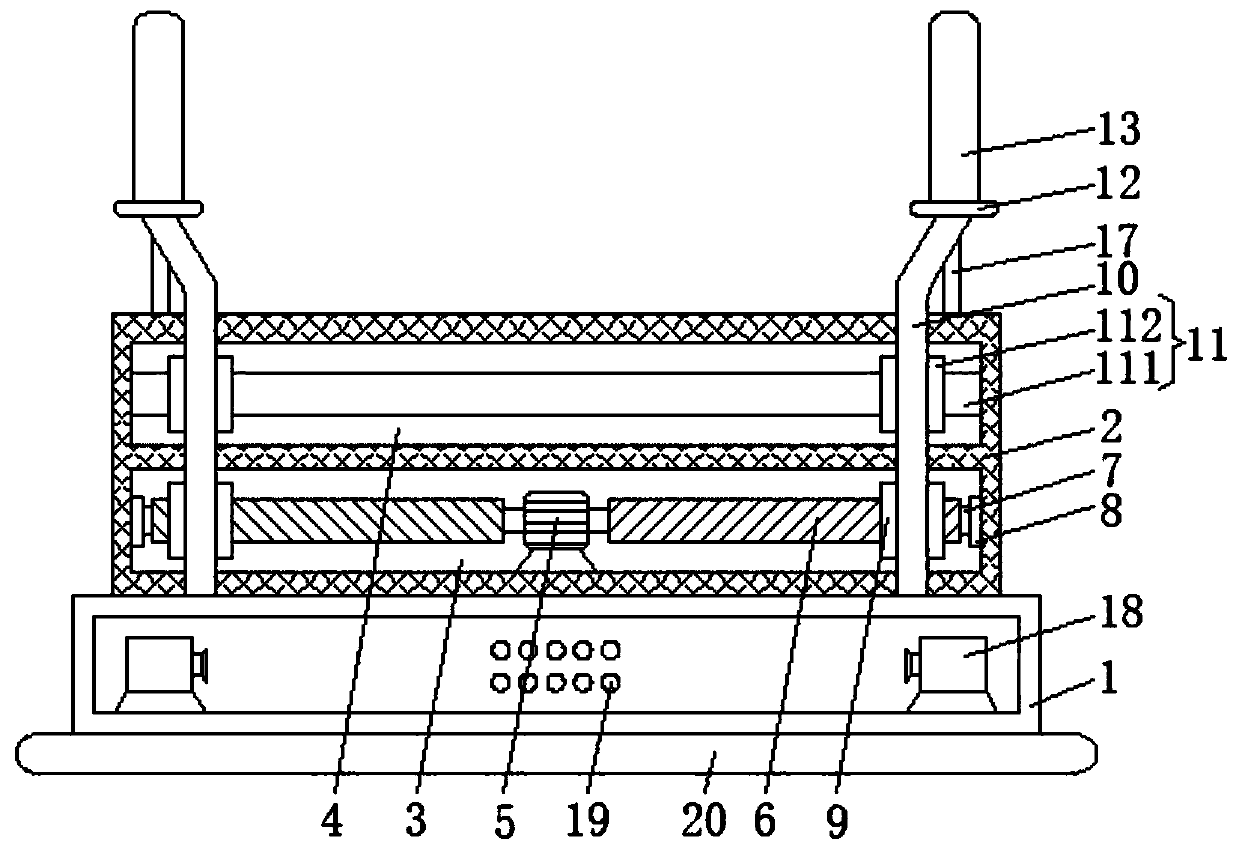

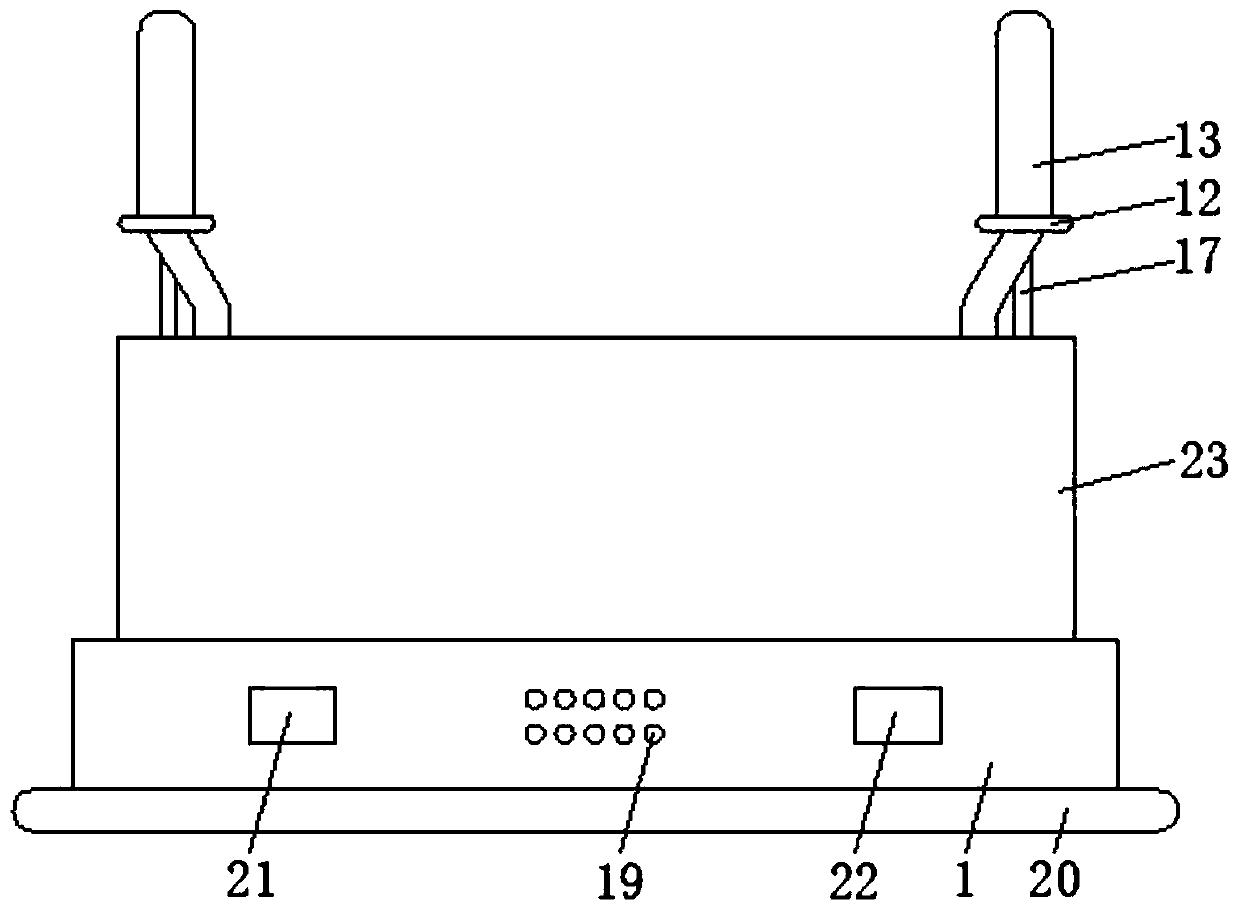

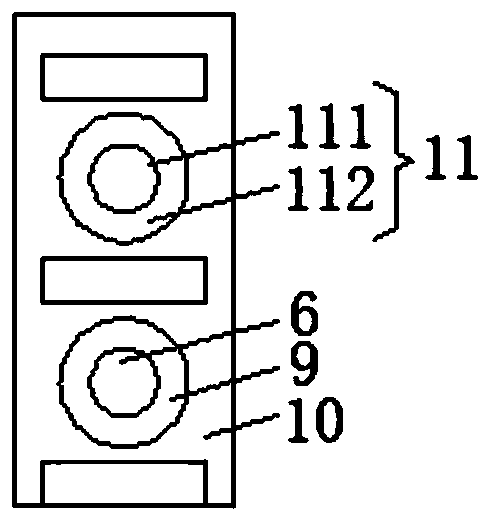

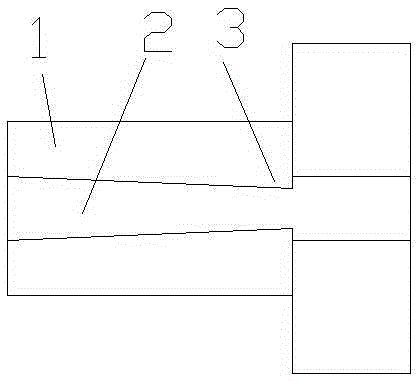

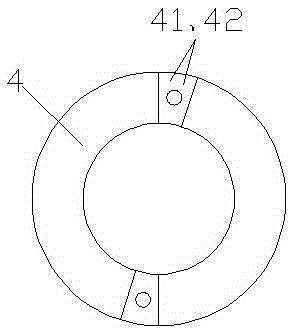

Sewage sludge treatment device

InactiveCN104098240AAchieve dryingRealize step-by-step processingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFreeze-dryingSewage

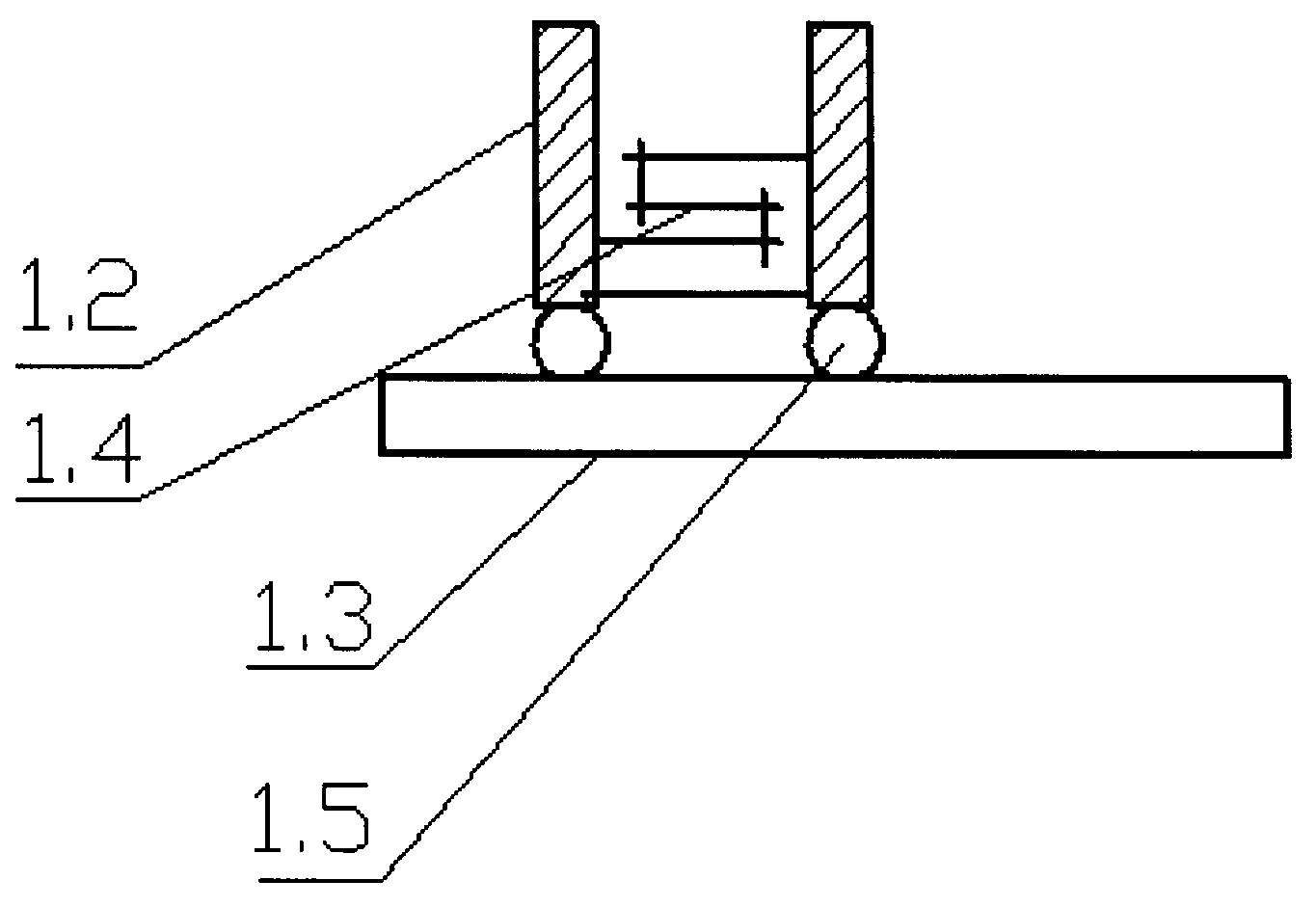

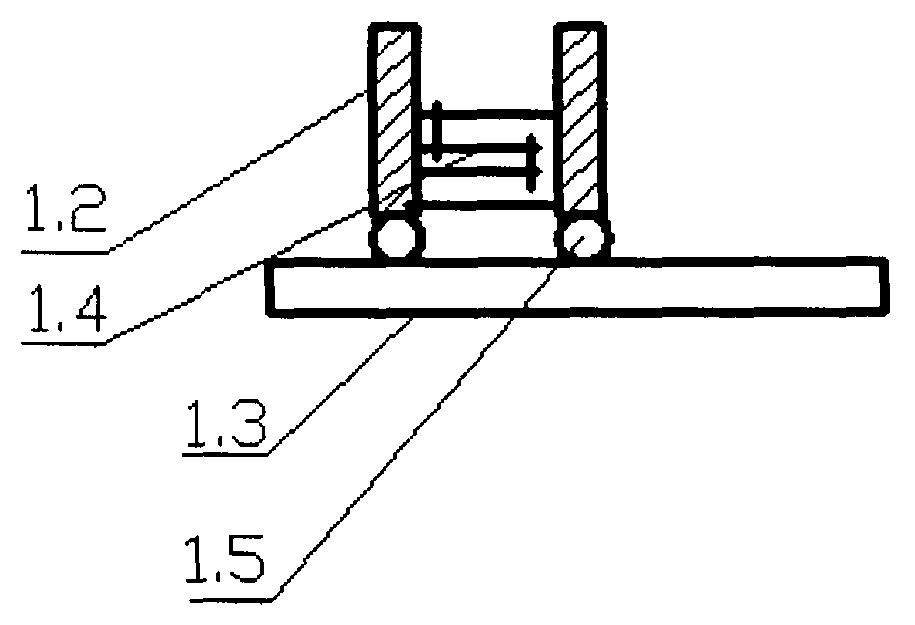

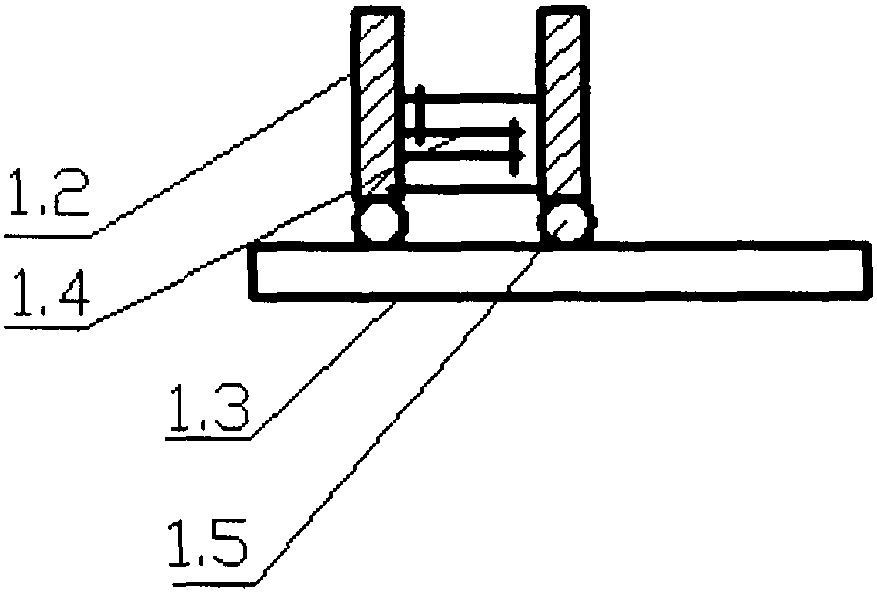

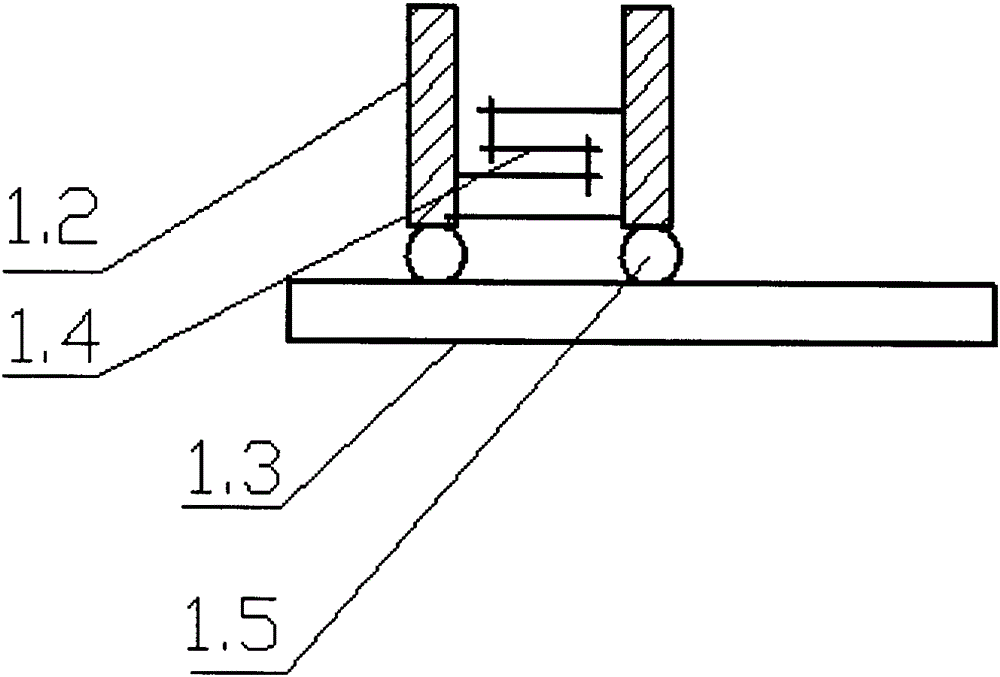

The invention discloses a sewage sludge treatment device which comprises a filter pressing device 1, a crushing device 2 and a drying device 3. The sewage sludge treatment device further comprises a sludge freezing container 4 and a freeze drying energy circulating system. The freeze drying energy circulating system comprises a compressor 5, a first evaporator 6, a condenser 7 and a second evaporator 8 arranged in the sludge freezing container. The air outlet end of the compressor is connected with the condenser, the condenser is connected with the first evaporator through a throttling element, the first evaporator is connected with the air inlet end of the compressor through the second evaporator, the condenser is communicated with the bottom of the drying device through a gas pipeline 10, the first evaporator is communicated with the top of the drying device through a gas pipeline, and the condenser is communicated with the first evaporator through a gas pipeline. According to the sewage sludge treatment device, chemical agents do not need to be added to sludge, the sludge treatment amount is not increased in the treatment process, and recycling of working medium energy greatly improves sludge freezing efficiency and heat utilization rate.

Owner:CHINA JILIANG UNIV

Advanced treatment method for sewage sludge

ActiveCN105693049AAchieve dryingDoes not increase throughputSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningWaste heat recovery unitFreeze-drying

The invention discloses an advanced treatment method for sewage sludge.The method is based on a sewage sludge treatment device, and the sewage sludge treatment device comprises a sludge refrigerating container(4), a freeze drying energy-cyclic system and a waste heat recovery device, wherein the freeze drying energy-cyclic system comprises a compressor (5), an evaporator (6), a condenser (7) and a first heat exchanger (8) arranged in the sludge refrigerating container.An air outlet end of the compressor is connected with the condenser which is connected with the evaporator through restricting elements.The evaporator is connected with an air inlet end of the compressor through the first heat exchanger.The condenser is communicated with the bottom of a dryer through a gas pipeline (10), the evaporator is in through connection with the top of the dryer through the gas pipeline, and at the same time, the condenser is in through connection with the evaporator through the gas pipeline.The recovered heat is used for sludge drying of the dryer and for sludge thawing.According to the advanced treatment method, the sludge treating capacity will not be increased in the treating process, and the sludge refrigeration efficiency and heat use ratio of the sludge can be improved by the cyclic utilization of the working medium energy.

Owner:杭州浩斌科技有限公司

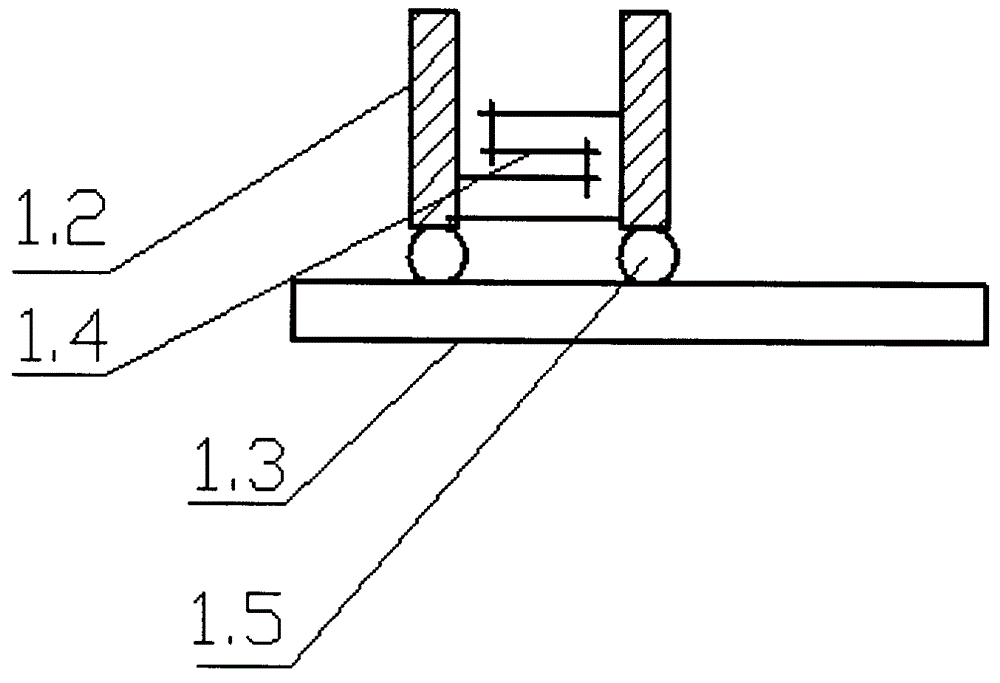

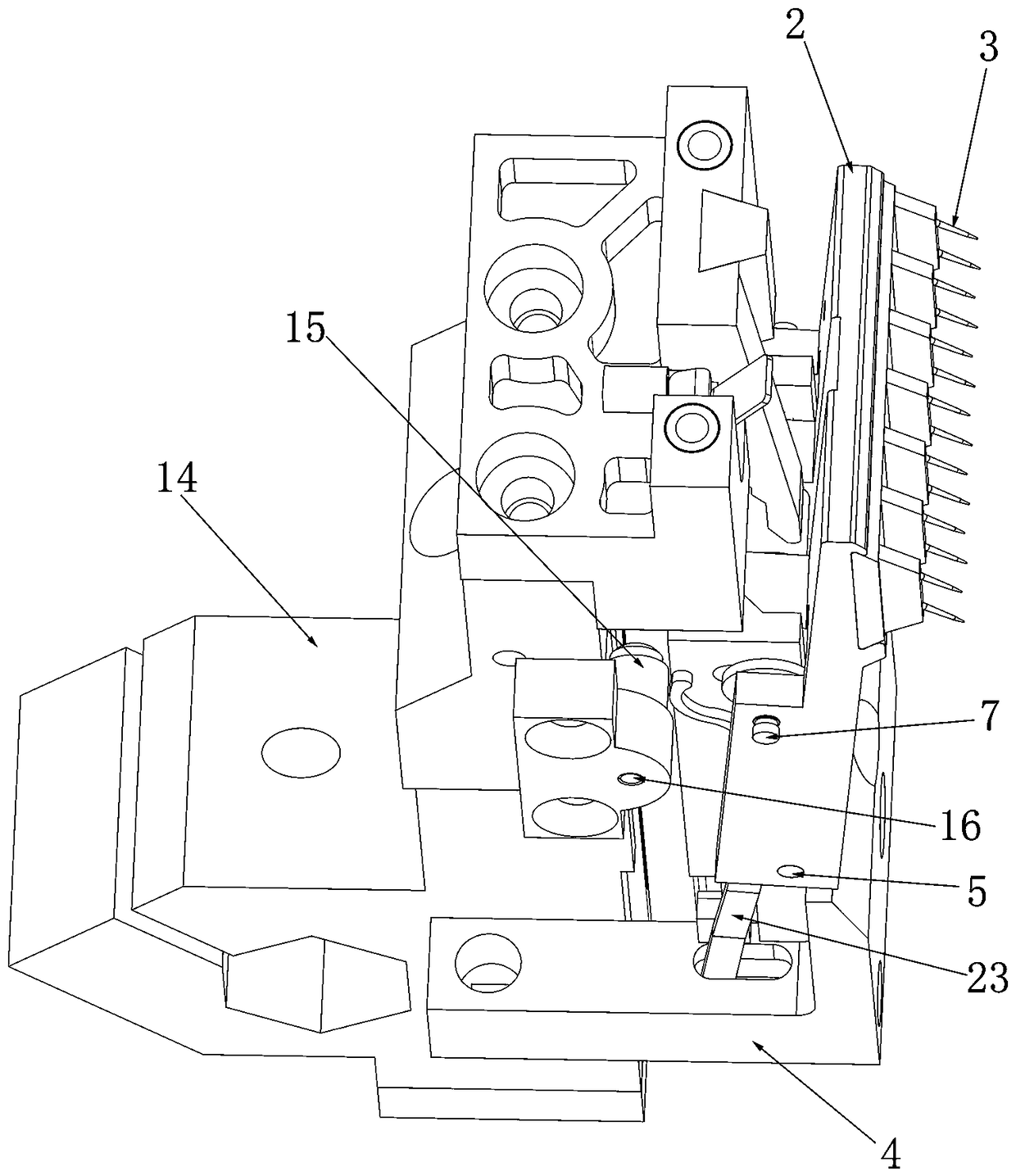

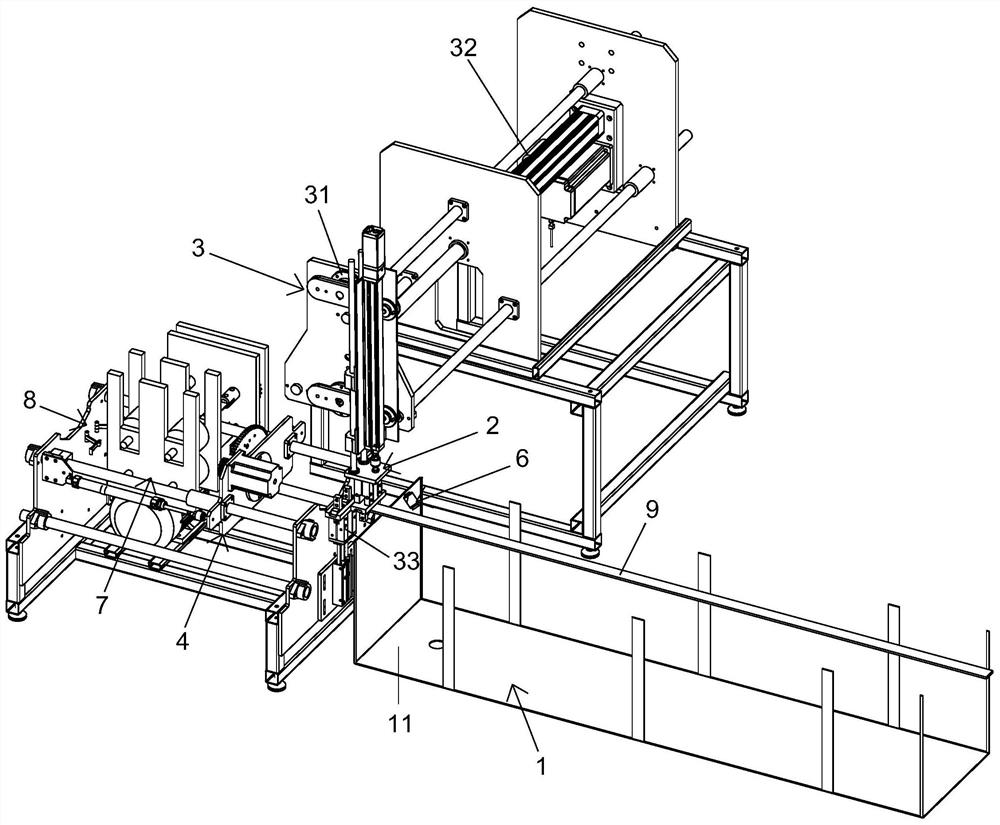

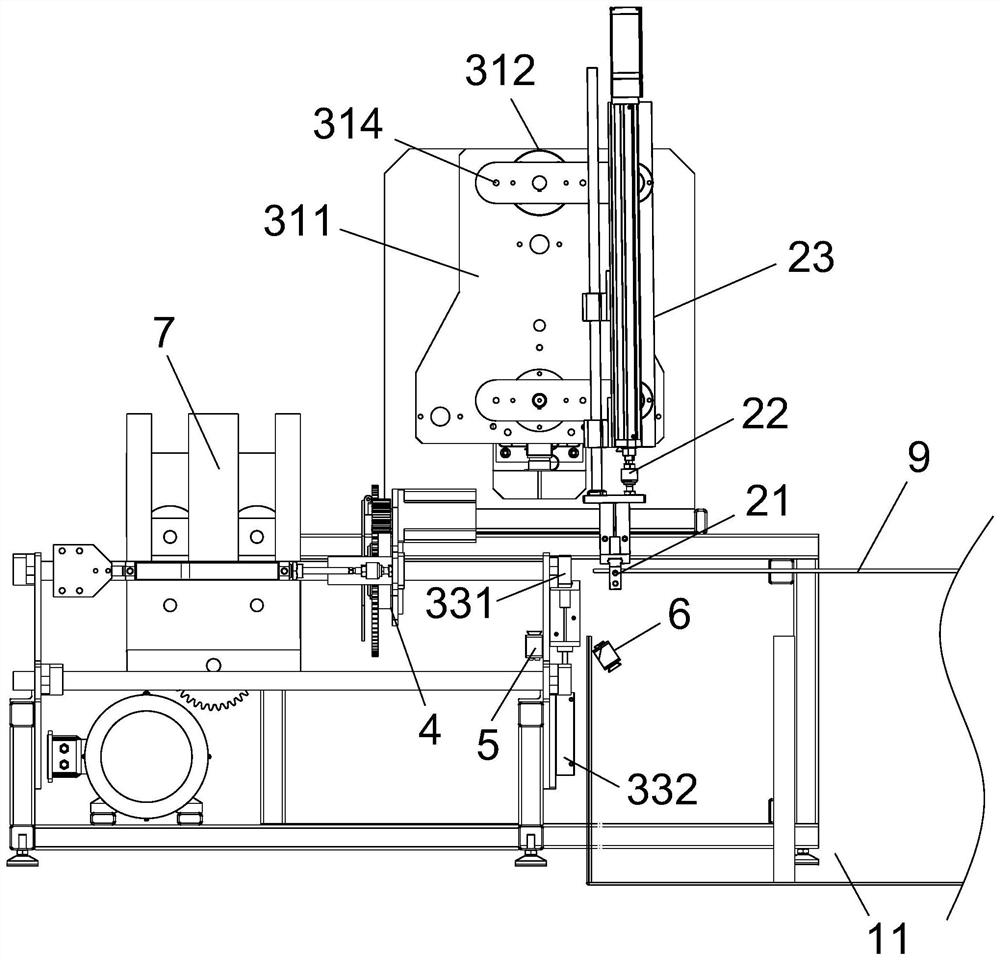

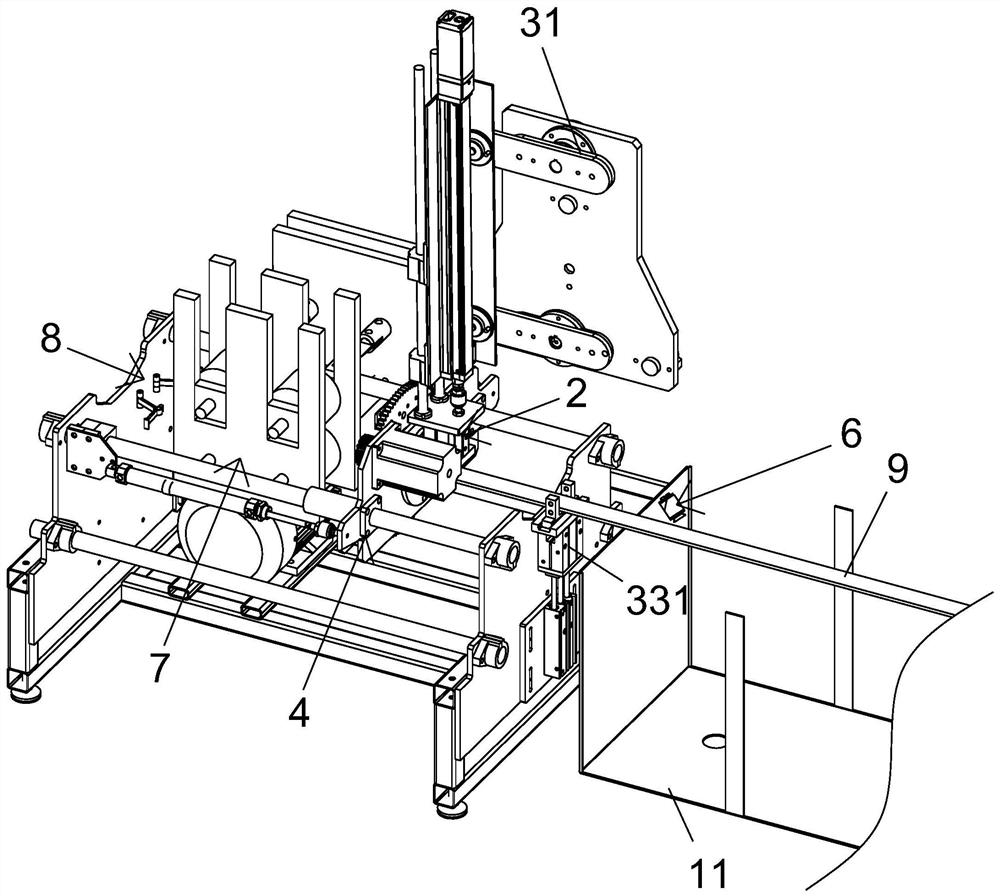

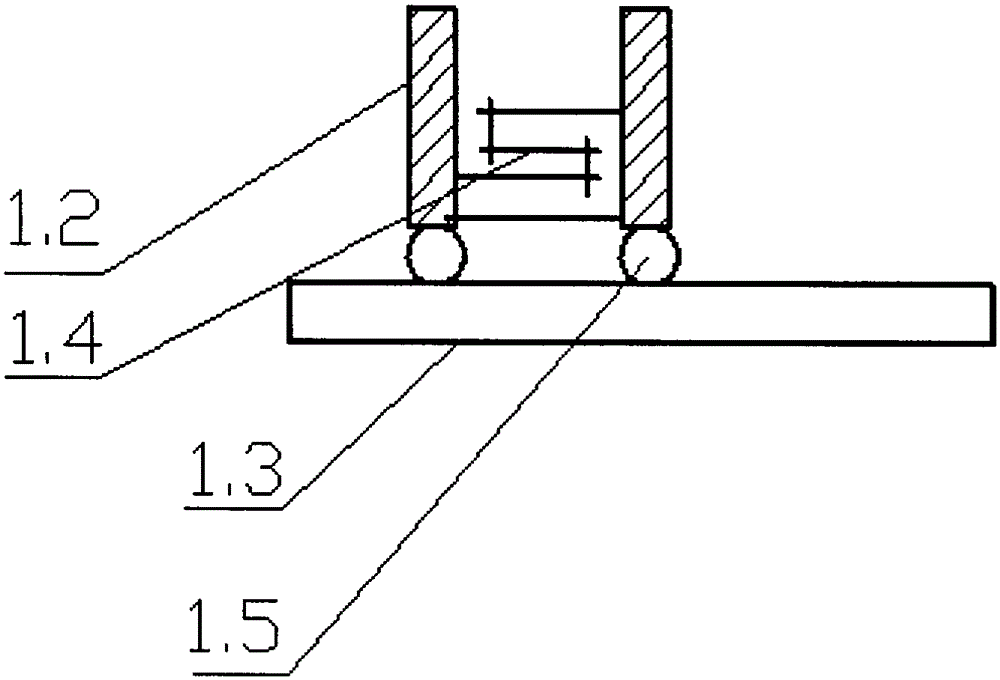

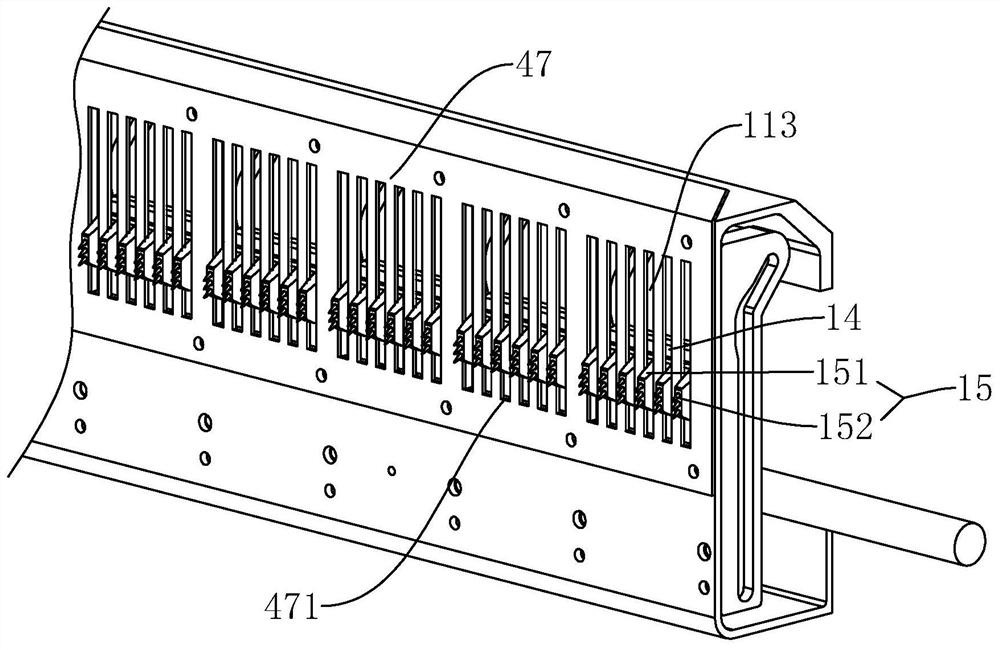

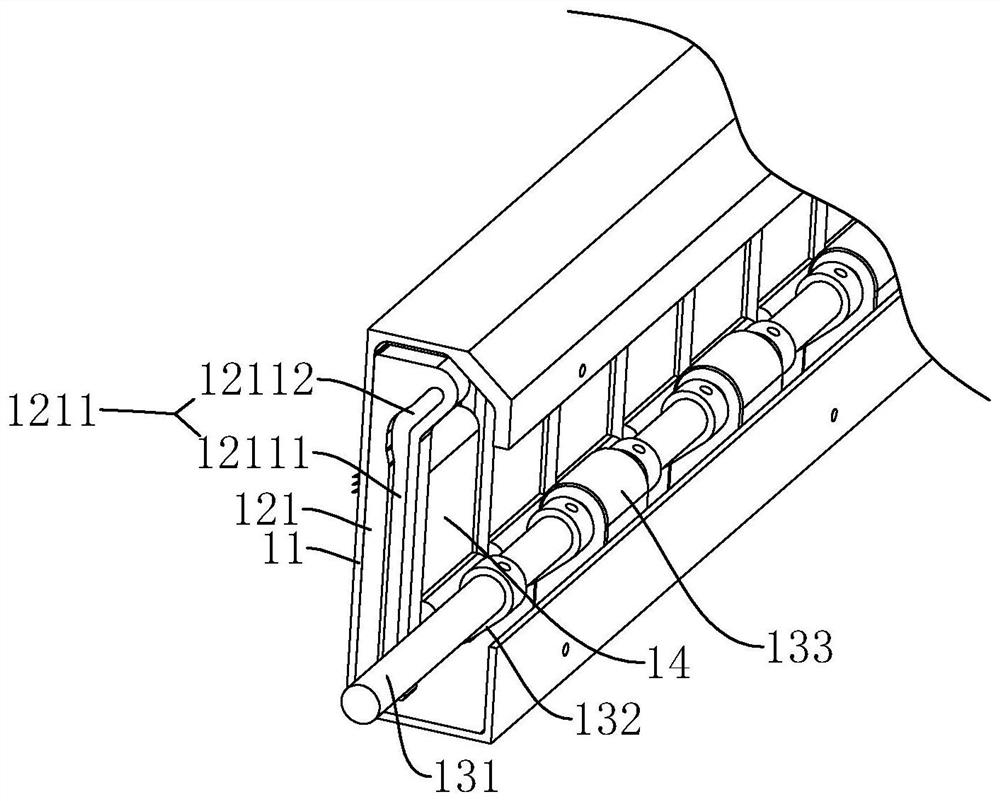

Traction device of knitting machine

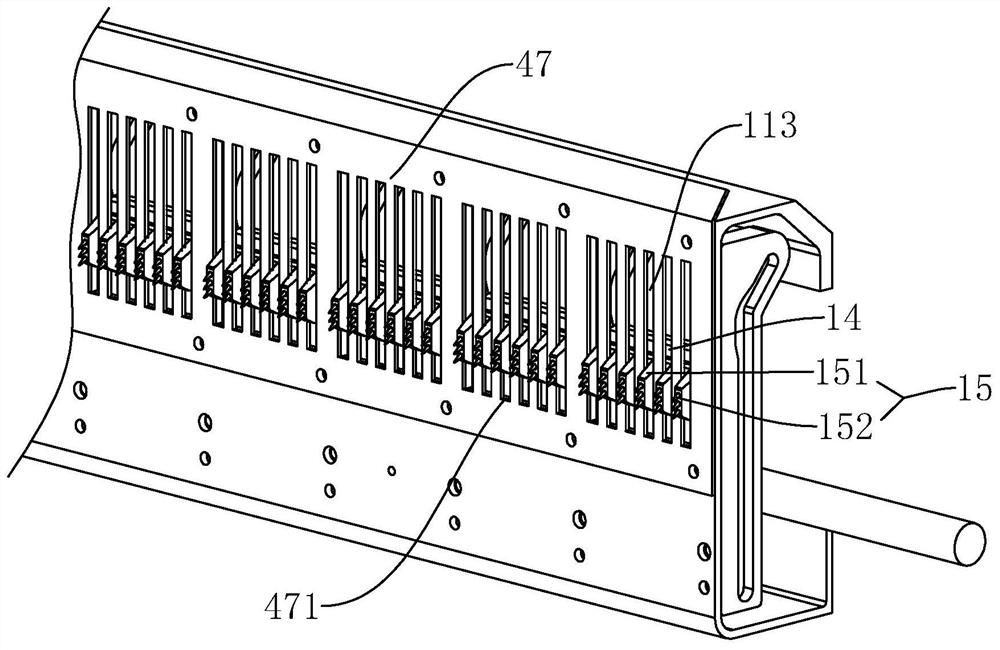

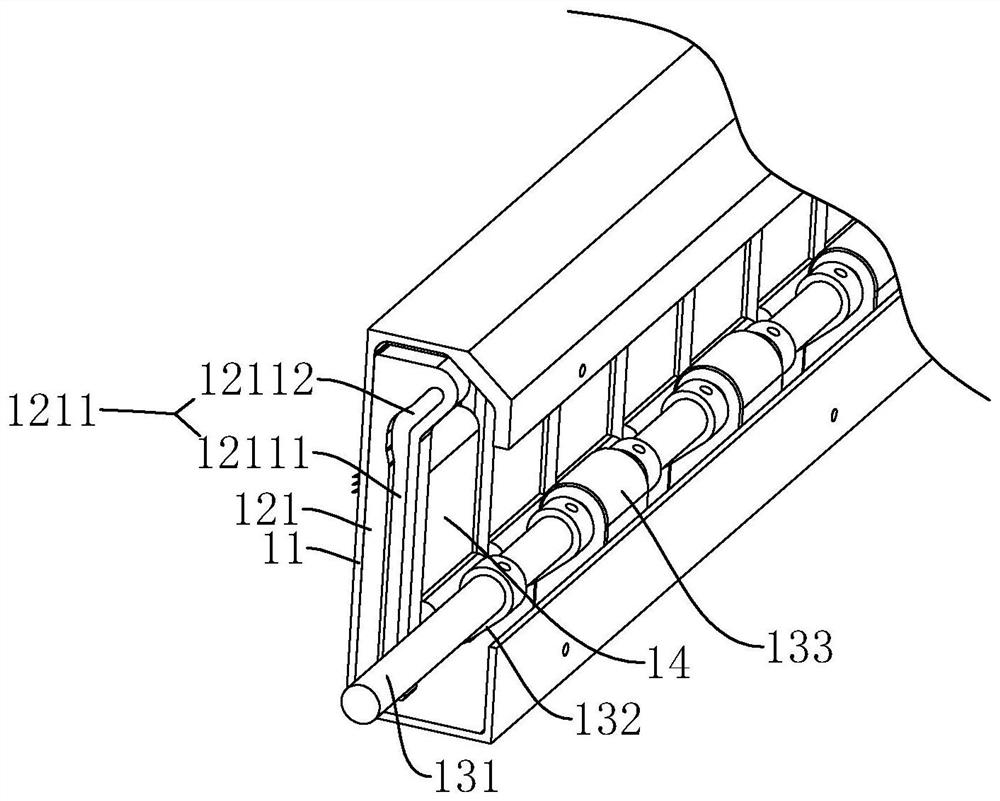

ActiveCN108642695AOvercoming elasticityPull to achieveWeft knittingWarp knittingEngineeringMechanical engineering

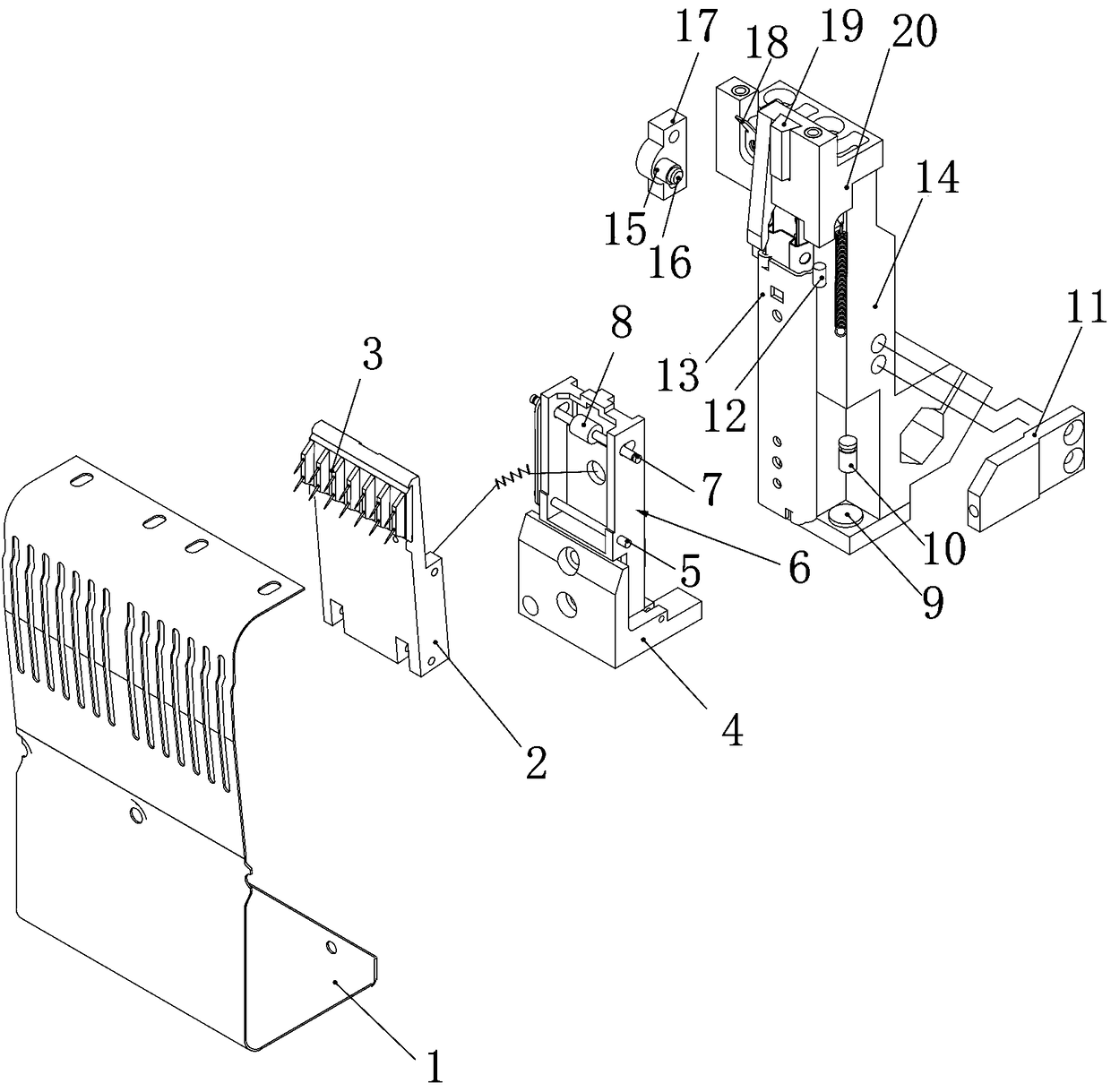

The invention discloses a traction device of a knitting machine. The traction device comprises multiple traction mechanisms arranged oppositely, wherein each traction mechanism comprises a gripper base with a gripper, a lifting seat and a fixing seat. A linear bearing seat is installed on the lifting seat, a first rotary shaft and a second rotary shaft are arranged on the linear bearing seat, thefirst rotary shaft is arranged in a long groove hole formed in the upper portion of the linear bearing seat, and the gripper base is installed on the two rotary shafts. A first pneumatic piston assembly driving the first rotary shaft to move in the long groove hole is arranged on the side face of the lifting seat, the first rotary shaft drives the corresponding gripper base to rotate around the second rotary shaft. A lifting tension spring for connecting the fixing seat and the lifting seat is arranged on the side face of the fixing seat, and a second pneumatic piston for pushing the corresponding lifting seat to move down is also arranged on the side face of the corresponding fixing seat. The traction device is provided with multiple independent traction mechanisms, the traction mechanisms can be freely selected to act and achieve double-side traction, single-side traction or certain-part traction on one side, selective fabric traction is achieved, and the traction device is speciallysuitable for completely formed knitting machines.

Owner:NINGBO CIXING

Pulling device of knitting machine

PendingCN110685063APull to achieveQuality assuranceWeft knittingWarp knittingStructural engineeringMechanical engineering

The invention discloses a pulling device of a knitting machine. The pulling device comprises a plurality of rake type pulling mechanisms; each rake type pulling mechanism comprises a claw assembly lift base, a claw assembly fixture and a stop mechanism; a regulating mechanism is arranged on the side of the fixture; the stop mechanism is arranged below a regulating mechanism beside the fixture; theclaw assembly comprises a claw holder and a claw holder separator block, a claw is arranged on the upper portion of the claw holder through the claw holder separator block and the claw holder is mounted on the lift base; a claw roller shaft and a claw holder rotating shaft are arranged on a linear bearing block up to down, the claw holder is mounted on the claw roller shaft and the claw holder rotating shaft, and the claw roller shaft is mounted in a long slot of the linear bearing block; the claw roller shaft moves reciprocatingly in the long slot to allow the claw holder to drive the claw holder separator block and the claw to swing inwards and outwards. The rake type pulling mechanisms of the pulling device are independent mutually, and can be selected optionally to do pulling, and thus, selective pulling to the fabric can be achieved.

Owner:NINGBO CIXING

Full-automatic bamboo cane feeding device

PendingCN112157756AHigh degree of automationAvoid Stuck SituationsWood feeding arangementsCane mechanical workingAgricultural engineeringMechanical engineering

The invention relates to a full-automatic bamboo cane feeding device. The full-automatic bamboo cane feeding device comprises a feeding mechanism, a grabbing mechanism, a conveying mechanism and a drawing mechanism, wherein the feeding mechanism comprises a feeding frame used for stacking bamboo canes; the grabbing mechanism is arranged above the feeding frame and comprises grabbing parts used forclamping the left side edge and the right side edge of a bamboo cane, a lifting power part used for driving the grabbing parts to vertically move and a grabbing base used for fixing the lifting powerpart; the conveying mechanism comprises a conveying driving assembly used for driving the grabbing mechanism to do arc-shaped motion in the front-back direction. The invention aims to provide the efficient and intelligent full-automatic bamboo cane feeding device. The full-automatic bamboo cane feeding device has the advantages that the full-automatic bamboo cane feeding device comprises the feeding mechanism, the grabbing mechanism, the conveying mechanism and the drawing mechanism; the grabbing mechanism can automatically grab the bamboo canes in the feeding mechanism and accurately feeds the bamboo canes into a sectioning machine or other conveying mechanisms through cooperation of the conveying mechanism and the drawing mechanism; manual participation is not needed in the feeding process; and the automation degree is high.

Owner:林树

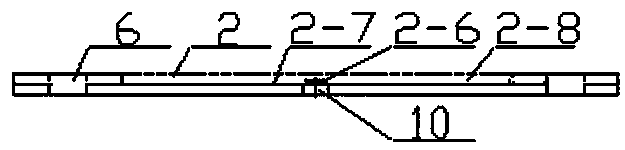

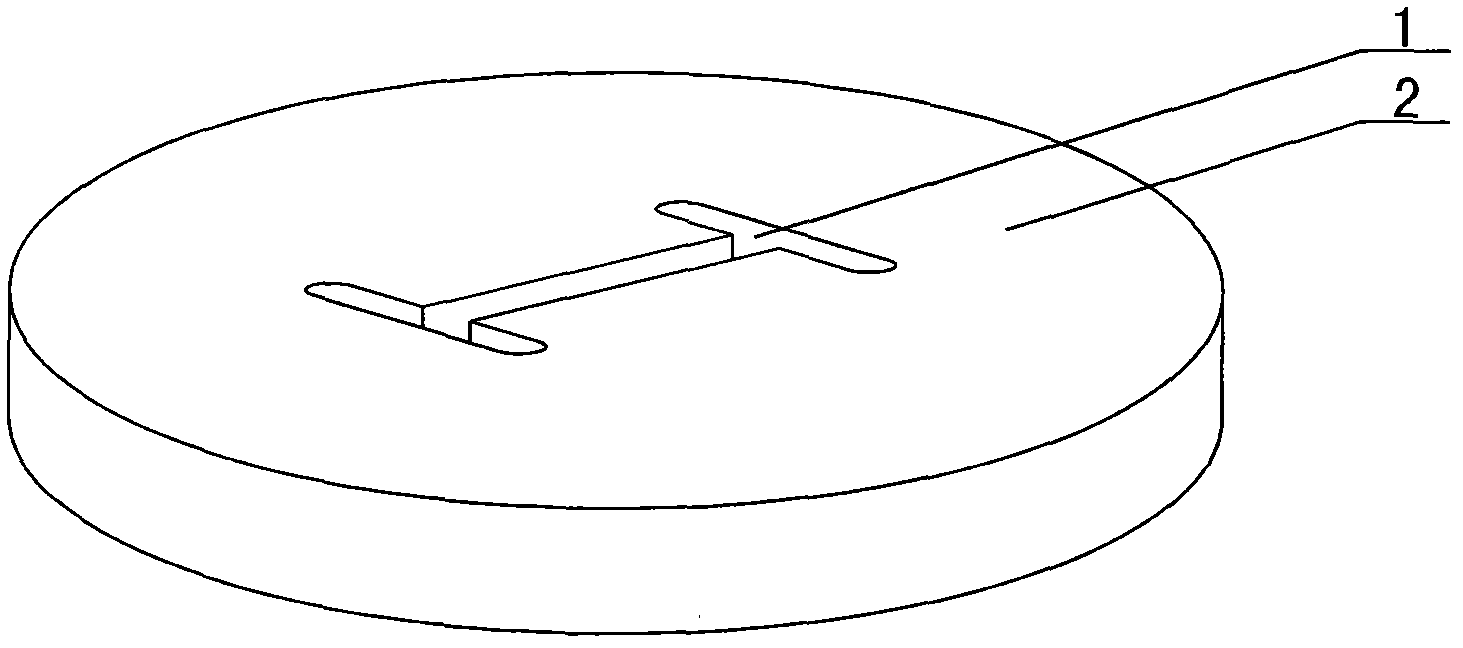

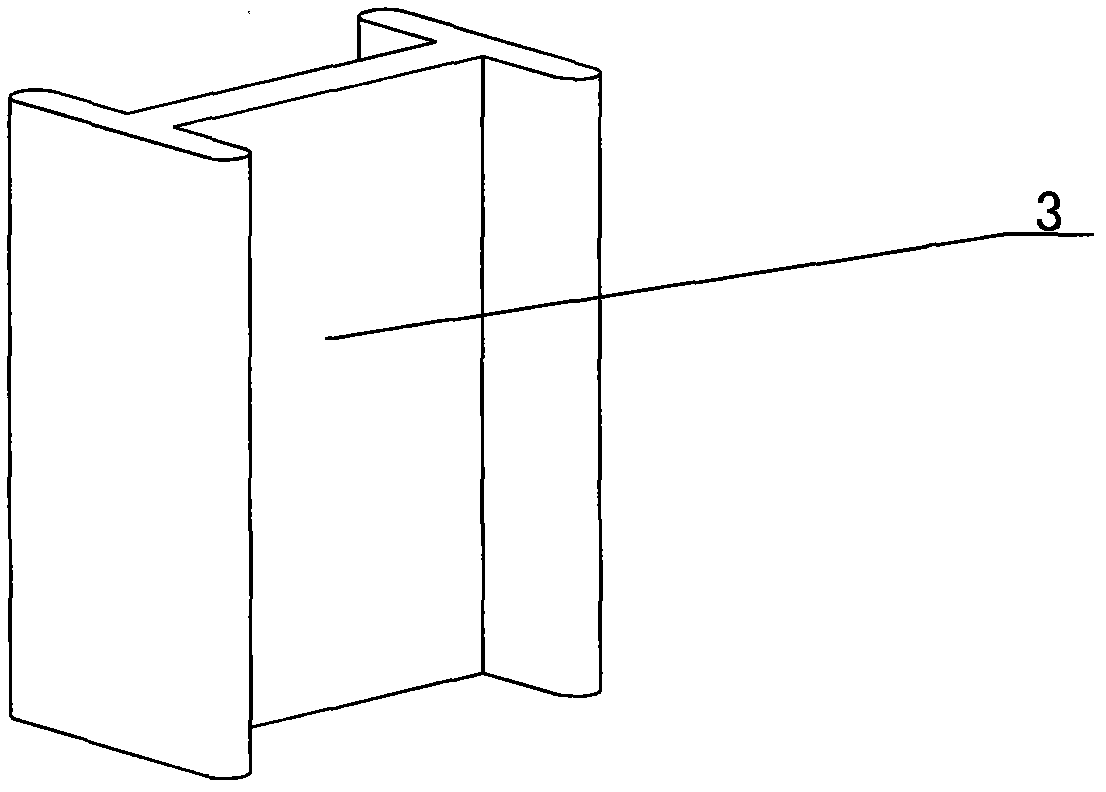

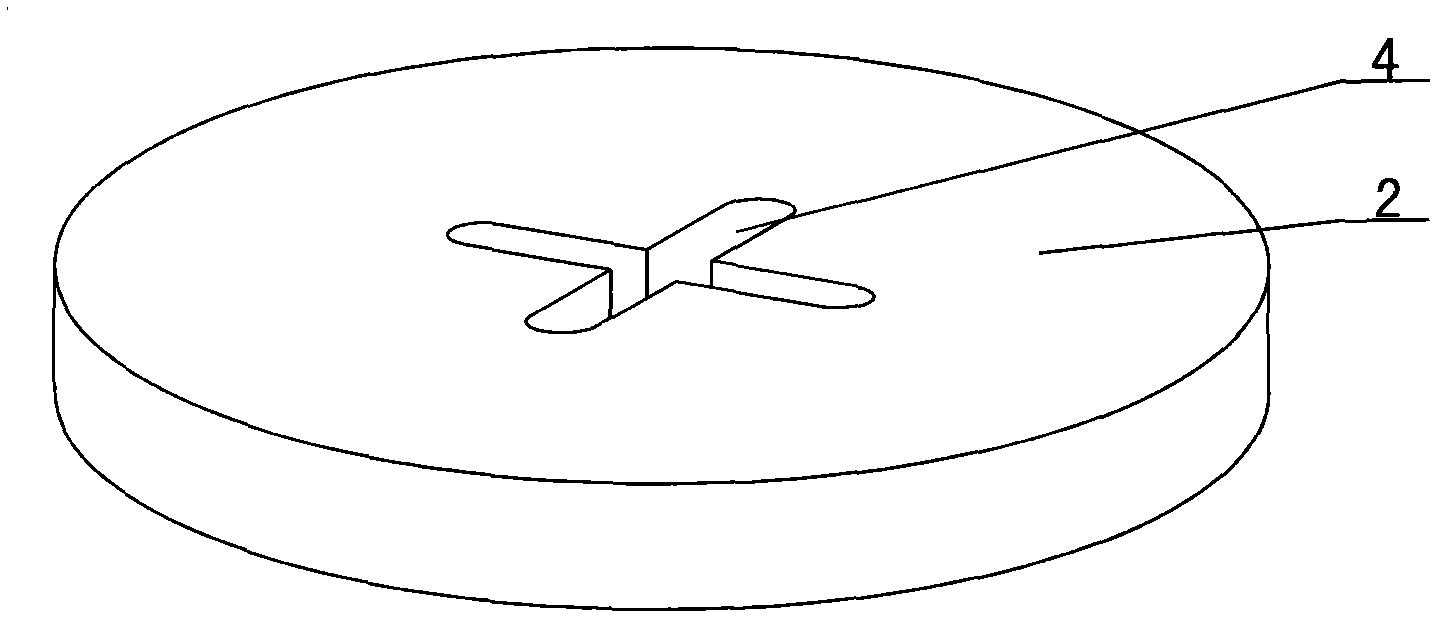

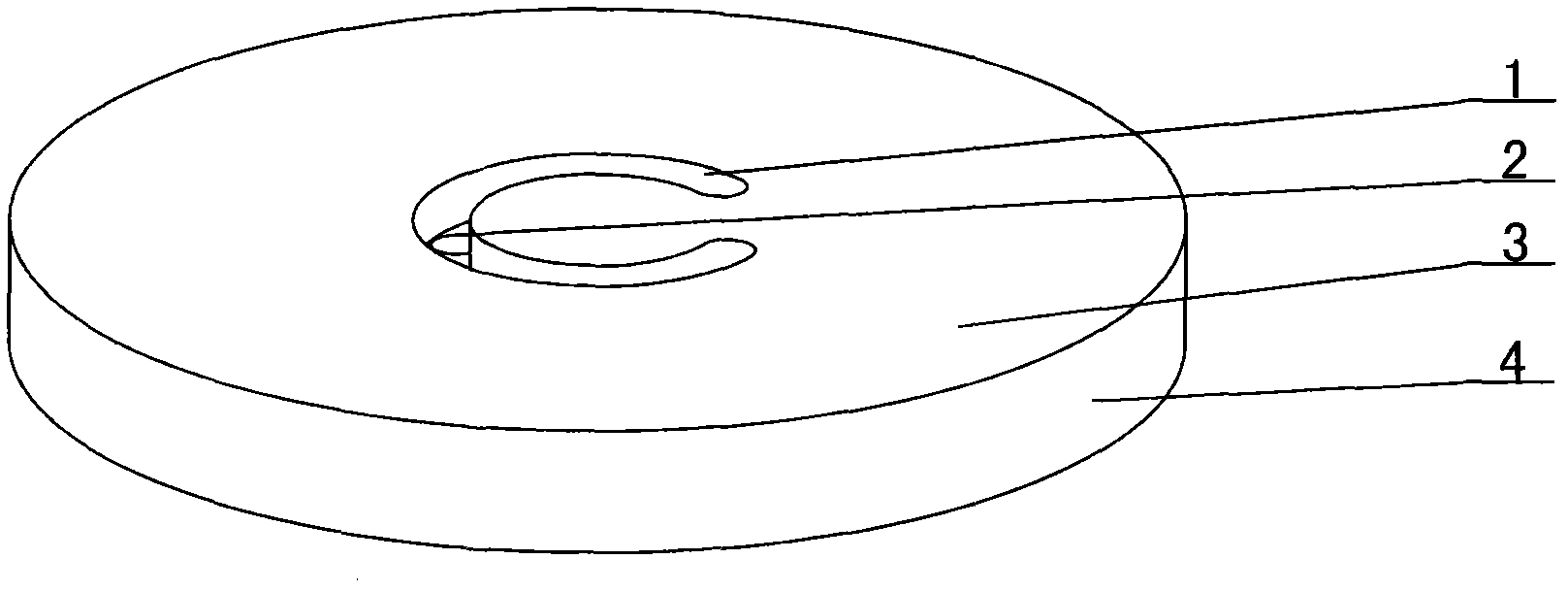

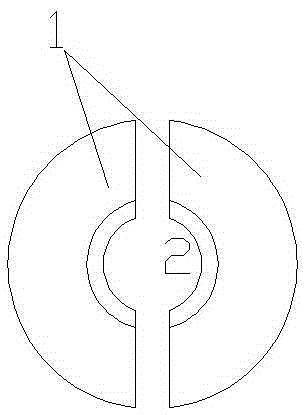

Drawing die plate for specially-shaped silicon core

InactiveCN103160916APull to achieveFantastic ideaPolycrystalline material growthBy pulling from meltChinese charactersEngineering

The invention discloses a drawing die plate for a specially-shaped silicon core, and relates to a die plate. The drawing die plate for a specially-shaped silicon core comprises a die plate (2) and a drawing groove, wherein the drawing groove is formed in the die plate, the drawing groove is any one of an I-shaped groove (1), a cross-shaped groove (4), a double-cross-shaped groove (6), a six-Chinese-character-shaped groove (8), an S-shaped groove (10) or a Z-shaped groove (12), and a crystal solution passage penetrating to the bottom of the die plate is formed in the bottom of the drawing groove (1); and the drawing die plate for a specially-shaped silicon core disclosed by the invention is used for realizing drawing for the specially-shaped silicon core by forming the specially-shaped drawing groove in the die plate, enabling the melted crystal solution to enter in the drawing groove, drawing out any one specially-shaped silicon core of an I-shaped silicon core, a cross-shaped silicon core, a double-cross-shaped silicon core, a six-Chinese-character-shaped silicon core, an S-shaped silicon core or a Z-shaped silicon core, and then pulling out the silicon core with the same shape via seed crystal with the same shape. The drawing die plate for the specially-shaped silicon core disclosed by the invention is wonderful in conception, simple in structure, and low in use cost; and the later-stage use effect of the specially-shaped silicon core is superior to the later-stage use effect of the existing cylindrical solid silicon core. The drawing die plate for the specially-shaped silicon core has certain market and application prospects.

Owner:LUOYANG JINNUO MECHANICAL ENG

Sewage sludge advanced treatment device

InactiveCN104098241BAchieve dryingRealize step-by-step processingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFreeze-dryingChemical agent

The invention discloses a sewage sludge advanced treatment device which comprises a crushing device, a drying device, a combustion device and a waste heat boiler. The sewage sludge advanced treatment device further comprises a sludge freezing container and a freeze drying energy circulating system. The freeze drying energy circulating system comprises a compressor, an evaporator, a condenser and a first heat exchanger arranged in the sludge freezing container. The air outlet end of the compressor is connected with the condenser, the evaporator is connected with the air inlet end of the compressor through the first heat exchanger, the condenser is communicated with the bottom of the drying device through a gas pipeline, and the evaporator is communicated with the top of the drying device through a gas pipeline. A heat conduction oil pipe is arranged in the waste heat boiler and performs heat transfer with air to heat the air, and the air heated is respectively conveyed to the drying device and the sludge freezing container to be used for sludge drying and unfreezing. According to the sewage sludge advanced treatment device, chemical agents do not need to be added, the sludge treatment amount is not increased, and sludge freezing efficiency and the heat utilization rate are improved through recycling of working medium energy and heat of sludge.

Owner:CHINA JILIANG UNIV

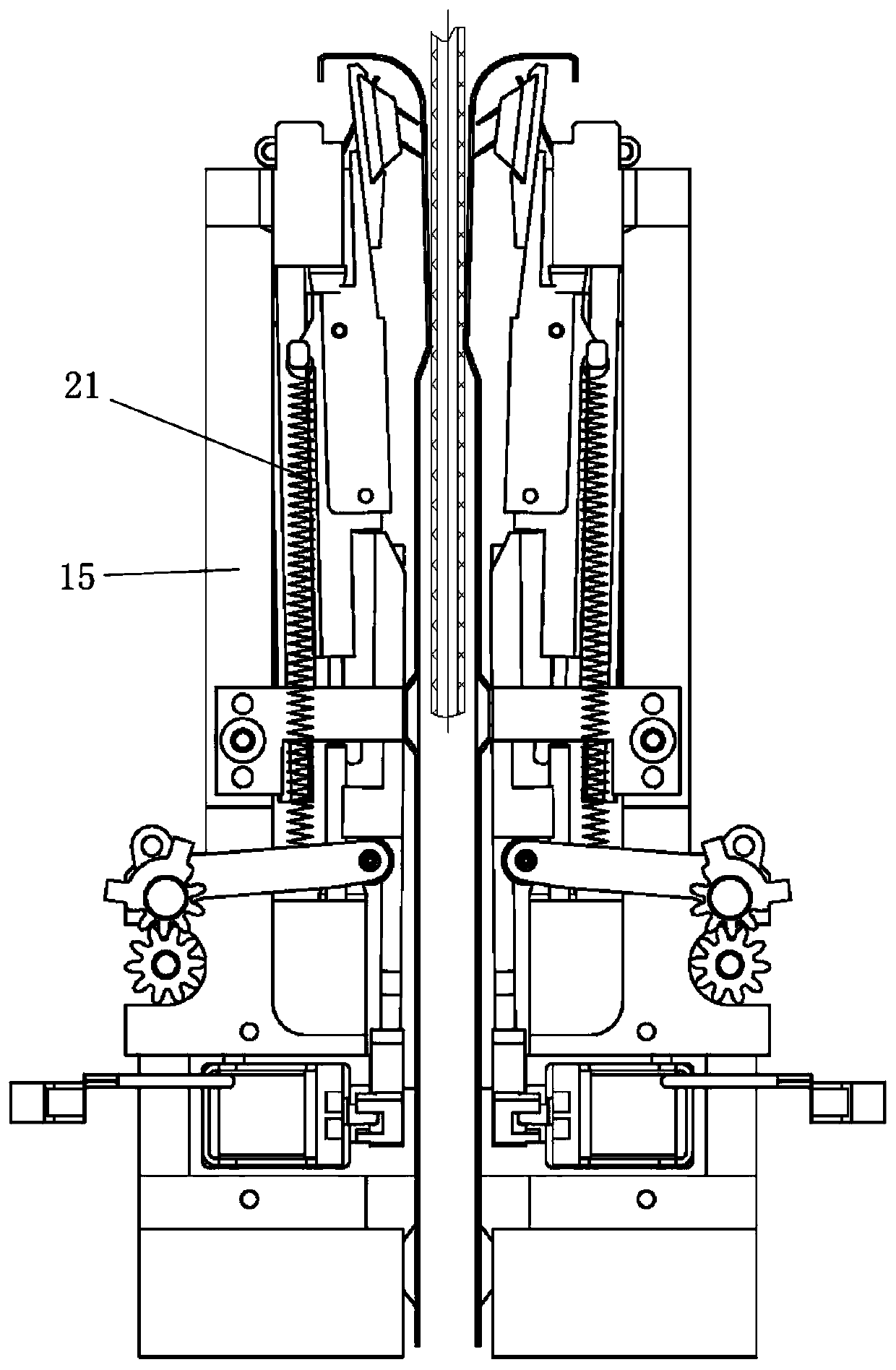

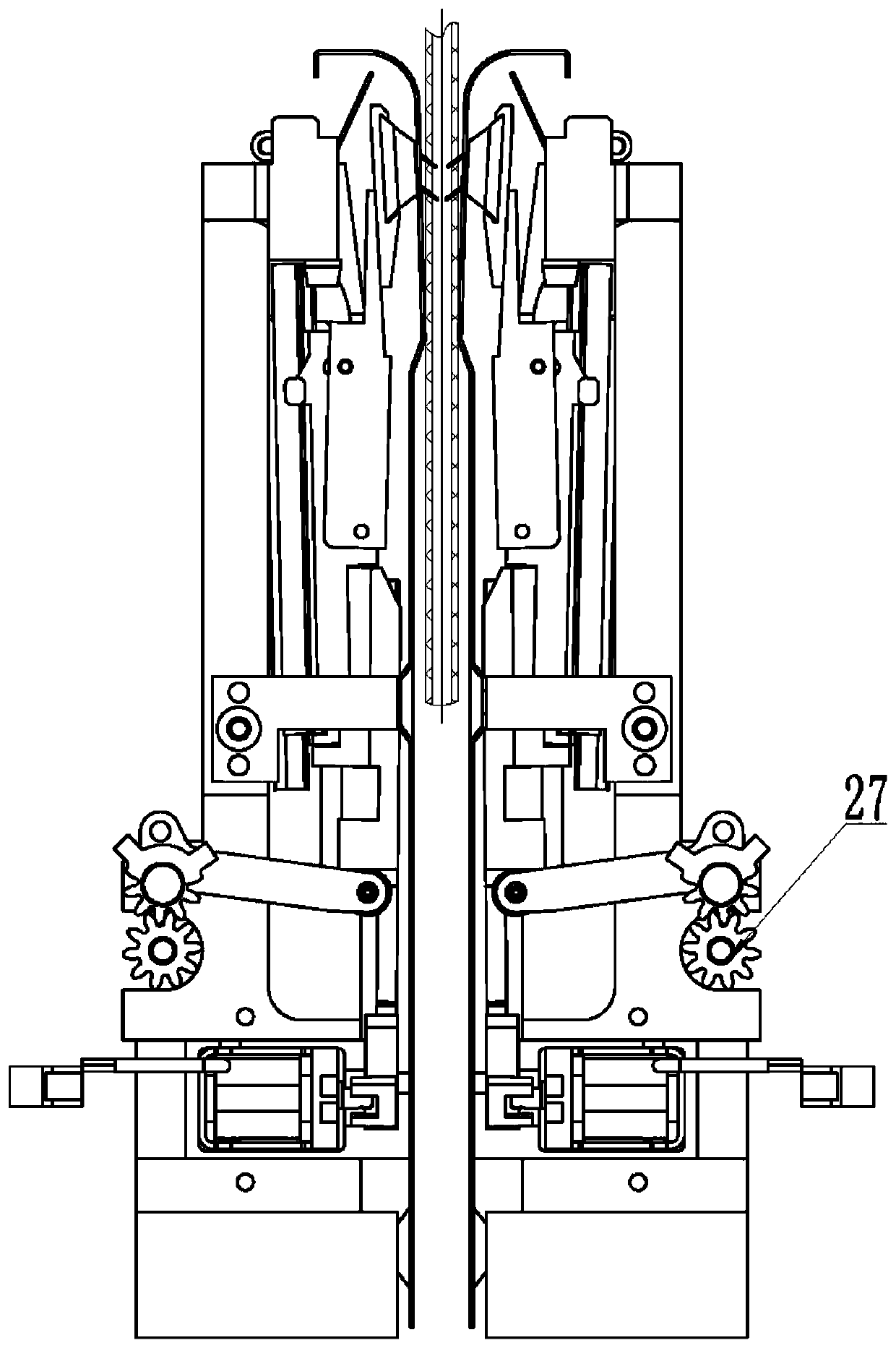

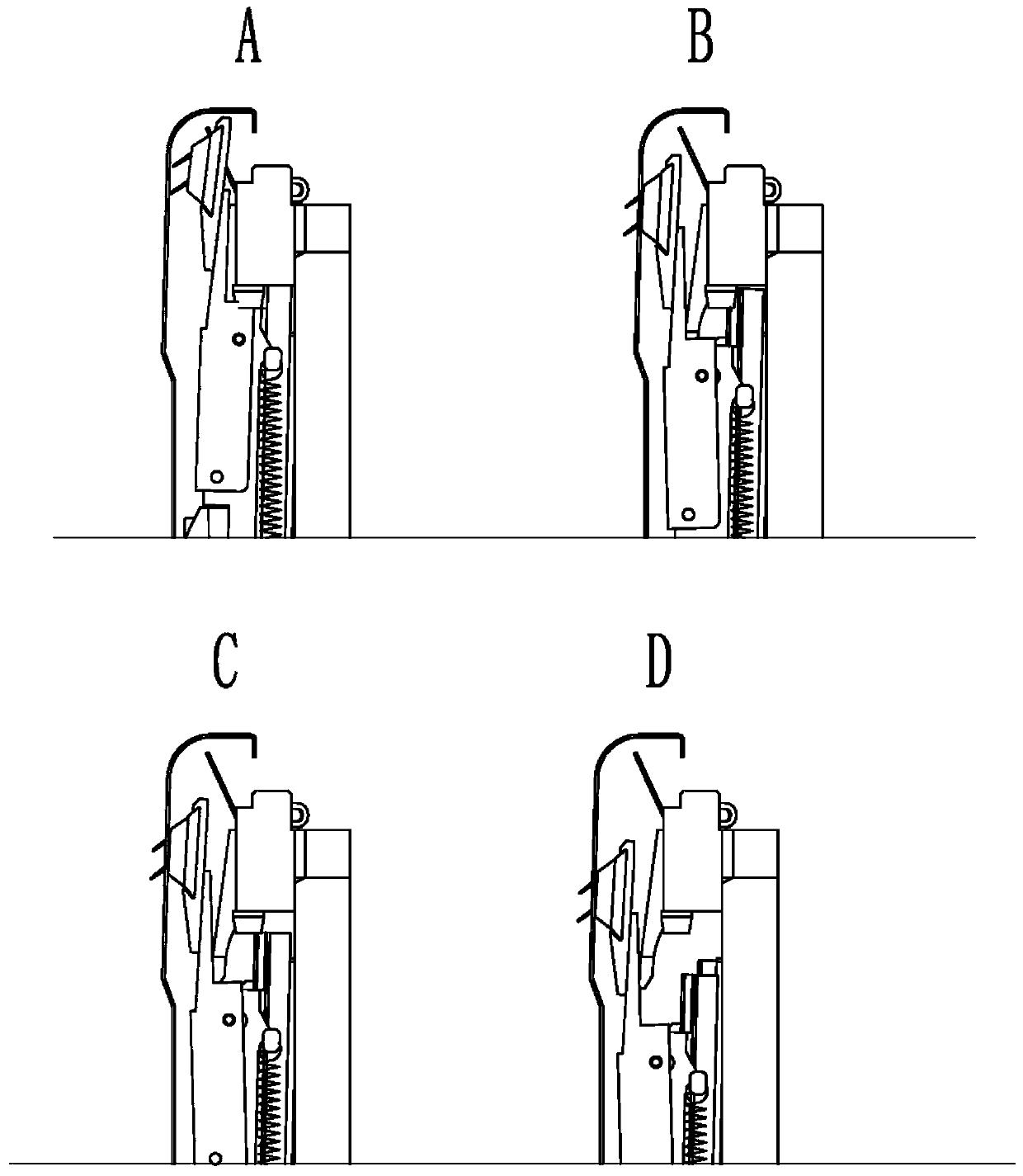

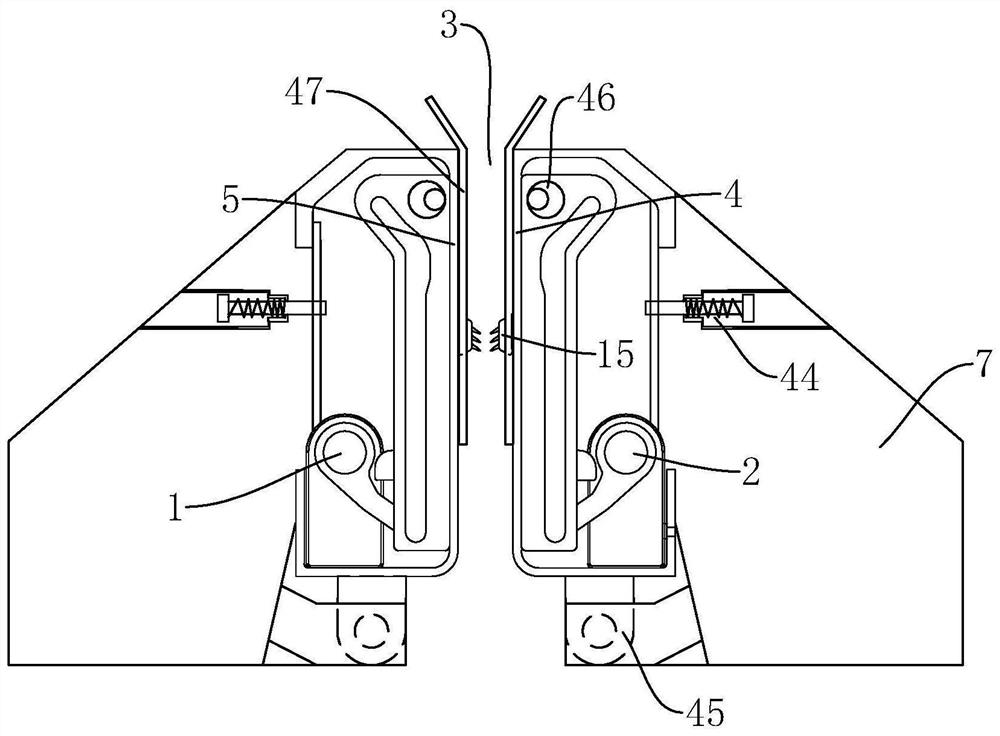

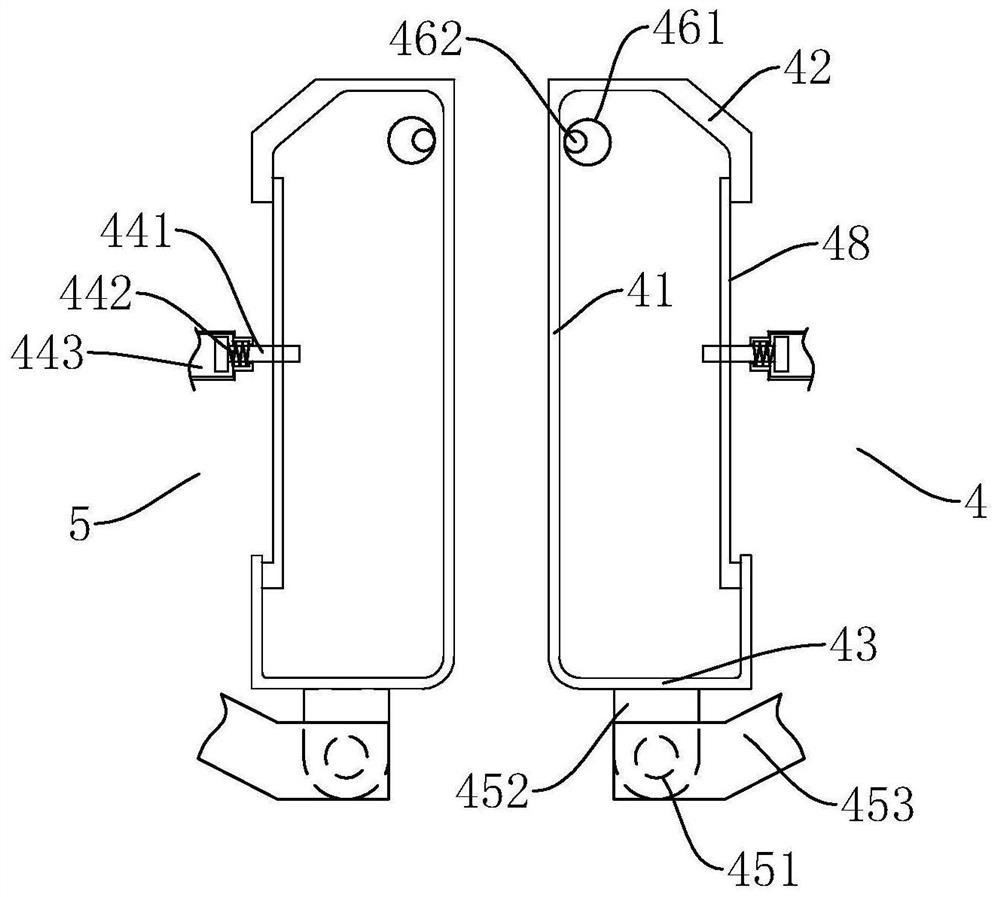

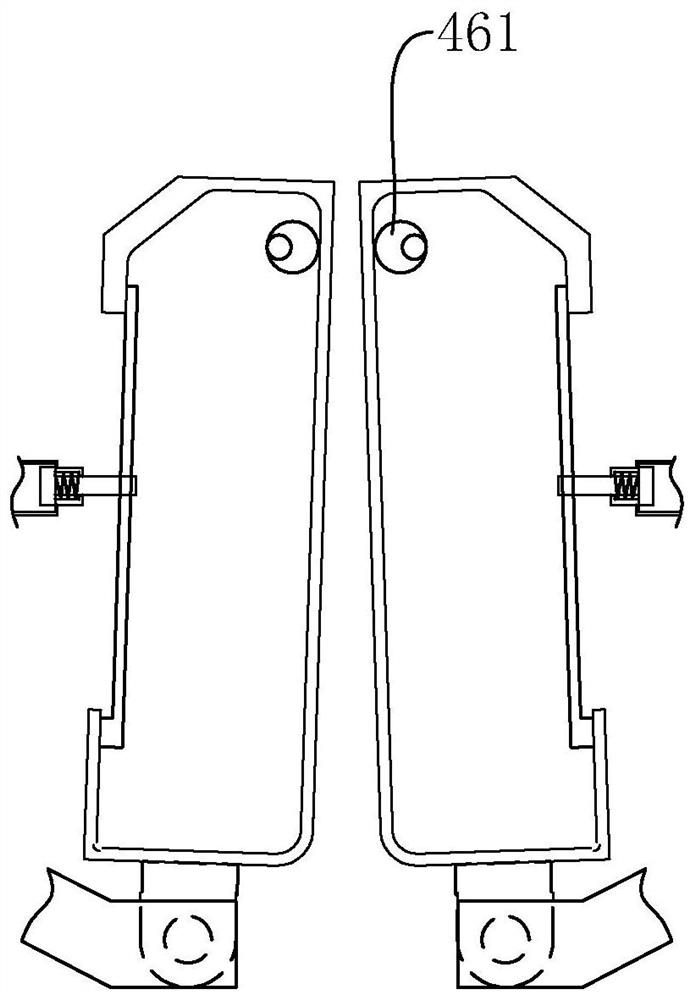

Pull-down opening and closing structure of computerized flat knitting machine

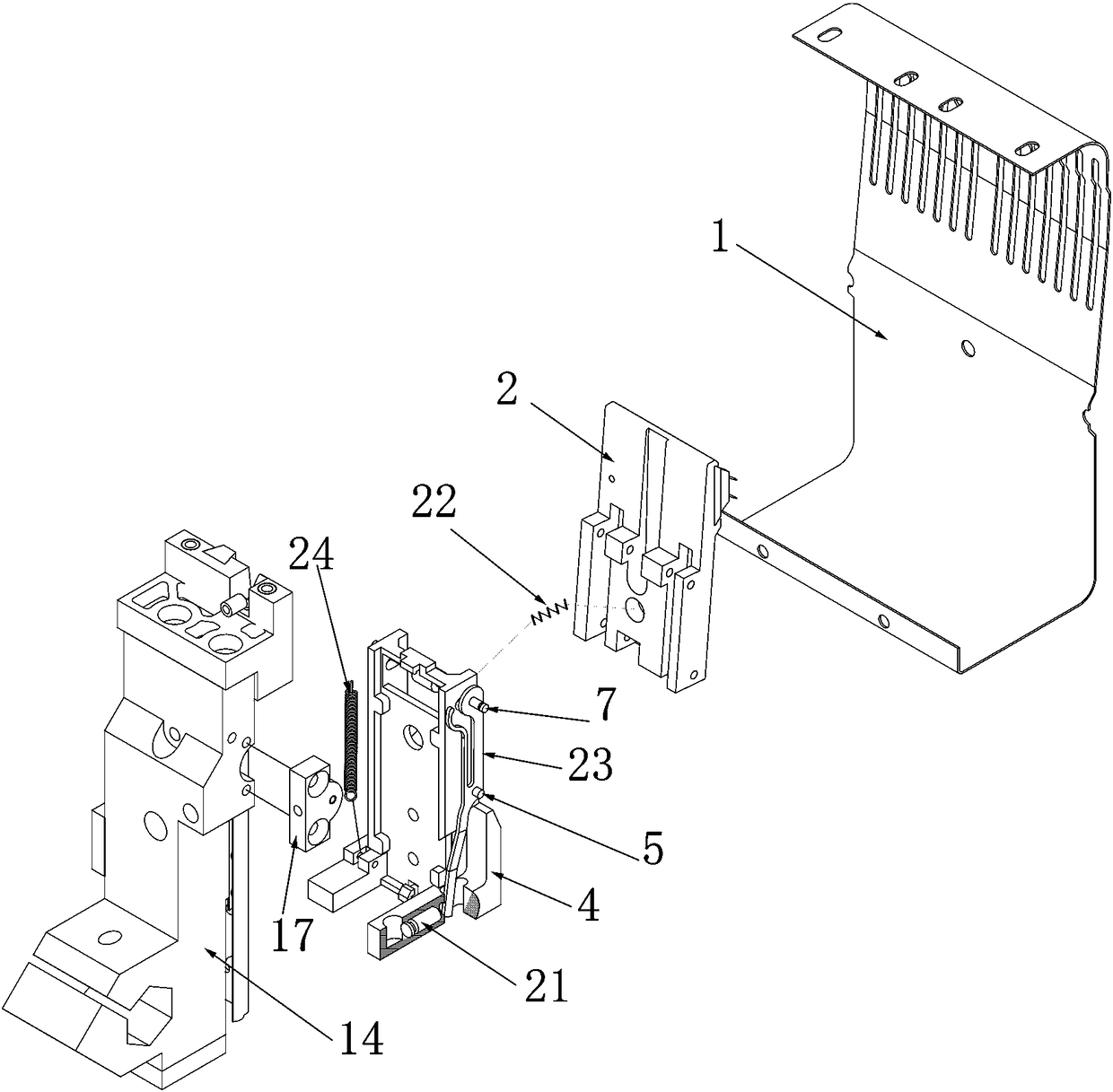

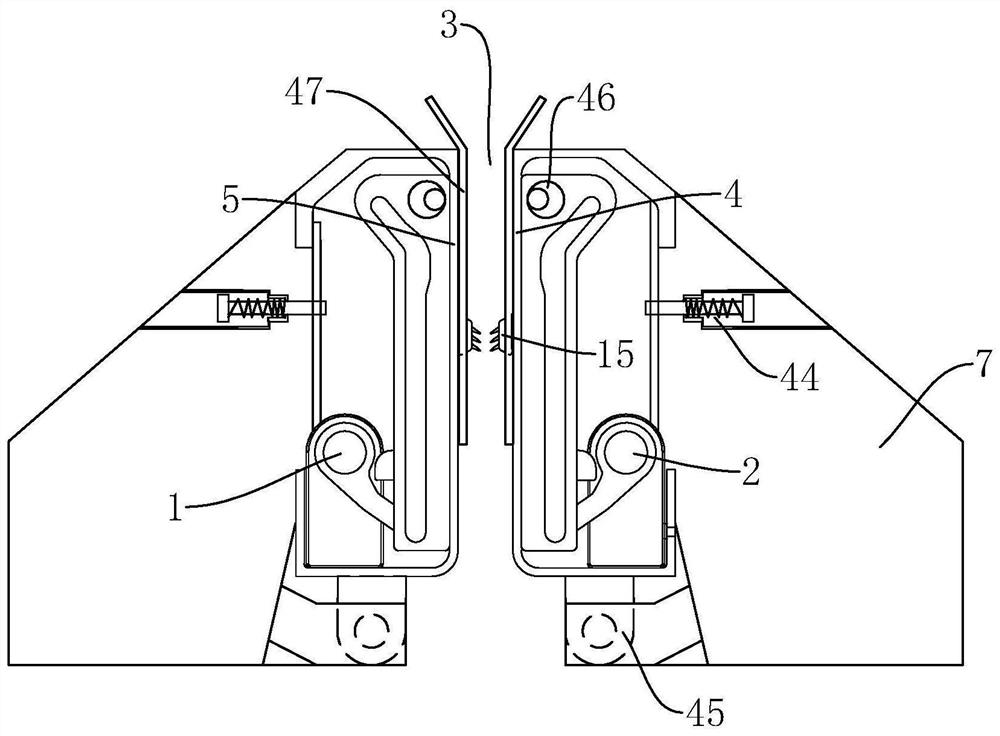

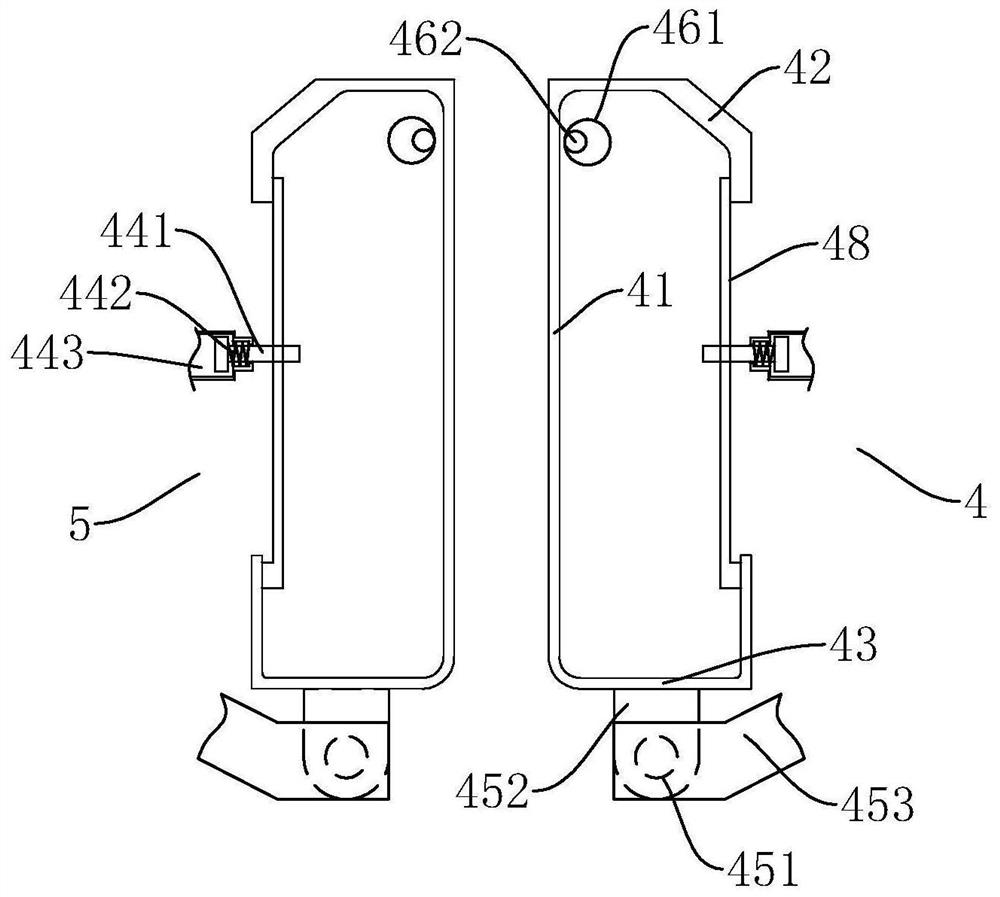

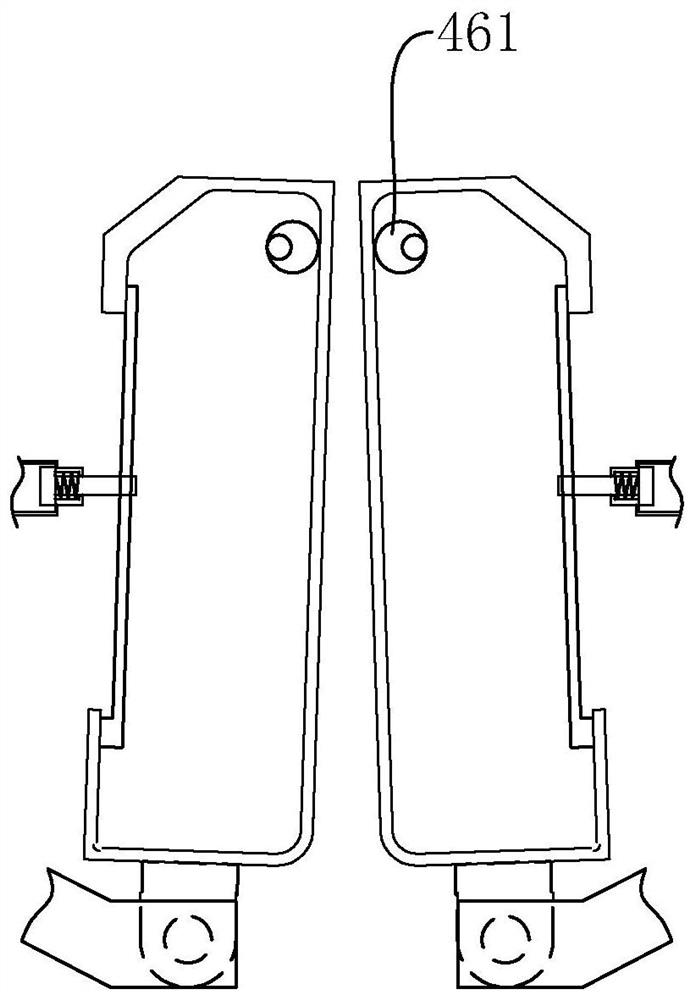

The invention discloses a pull-down opening and closing structure of a computerized flat knitting machine. The pull-down opening and closing structure comprises an opening and closing device and a rake type pull-down device, wherein the opening and closing device comprises a front plate frame and a rear plate frame which are symmetrical left and right, a traction channel is formed between the front plate frame and the rear plate frame, windows are formed in the front plate frame and the rear plate frame, swing driving assemblies are connected to the front plate frame and the rear plate frame,the rake type pull-down device comprises a left traction mechanism and a right traction mechanism, and each of the left traction mechanism and the right traction mechanism comprise a guide assembly, atraction rake and a traction driving assembly, the traction rake is installed on the back face of the front plate frame or the back plate frame through a guide assembly, a rake nail assembly is arranged on the side wall of the front face of the head of the traction rake, and the traction driving assembly is connected with the tail part of the traction rake. The structure is based on stable traction of fabric, and has the characteristics of simple structure, simplicity in operation and low cost.

Owner:无锡斯拓纺织科技有限公司

Vascular stretching device used for microsurgery in hand surgery department

InactiveCN109984850AEasy to pullPull to achieveInstruments for stereotaxic surgeryHand surgeryDrive motor

The invention discloses a vascular stretching device used for microsurgery in the hand surgery department, and relates to the technical field of vascular stretching devices. The vascular stretching device comprises a bottom frame, a vertical plate is arranged on the upper surface of the bottom frame, a first through hole and a second through hole are formed in the front side of the vertical plate,and a driving motor is arranged on the inner wall of the first through hole. According to the vascular stretching device used for the microsurgery in the hand surgery department, through the mutual cooperation of supporting plates, placement plates, ring sleeves, an air bag, threaded columns, thread caps and the driving motor, at this moment, the air bag is inflated, blood vessels can be simply positioned, at this time, the driving motor can be controlled to work to drive the threaded columns to rotate, the thread caps drive the supporting plates and the ring sleeves to move, the two ring sleeves move close to each other, and it can be achieved that the blood vessels on the two sides are stretched; the situation that in the blood vessel stretching process, the vascular stretching device shakes and the blood vessels on the two sides are misplaced can be prevented, and it can be ensured that the blood vessel suture process is smoothly carried out to a certain extent.

Owner:马丙栋

Branch pulling device used for agriculture and forestry

InactiveCN108157056APull to achieveAvoid constrictionCultivating equipmentsArchitectural engineeringScrew thread

The invention discloses a branch pulling device used for agriculture and forestry. The device comprises a left support, a right support, a bolt and a rope, the upper ends of the left support and the right support are connected together through a pin shaft, elastic rubber mats are installed on the inner sides the left support and the right support, and rope grooves are installed in the outer sides;the bolt passes through screw holes located in the lower ends of the left support and the right support to lock the left support and the right support together, the bolt is provided with a screw cap,and the bolt and the screw cap are in threaded connection; and the rope is installed on one rope groove, and a rope buckle is arranged on the rope. The device provided by the invention has simple operation and high working efficiency, and can be used repeatedly.

Owner:焦秀芳

Solid and liquid separator for materials

ActiveCN103657176BImprove stressThe moisture content of solids is reducedFiltration separationPush and pullLocking mechanism

The invention discloses a solid and liquid separator for materials. The solid and liquid separator comprises a frame, press plates, filter plates, a push-and-pull locking mechanism, a filter cloth mechanism, a filter cloth regeneration mechanism and a cleaning mechanism which are arranged on the frame, wherein the press plates and the filter plates are arranged on the frame in a sliding way alternately, and are matched to extrude a material, so that solid and liquid of the material can be separated; the push-and-pull locking mechanism is used for locking, pushing away all the press plates and filter plates, so that solid-liquid separation operation can be performed, or the material can be discharged; the filter cloth mechanism is used for separating solid and liquid of the material when the material is extruded; the filter cloth regeneration mechanism is used for washing to regenerate the filter cloth after the material is discharged; the cleaning mechanism is used for cleaning the material attached to the separator after solid and liquid of the material are separated. The solid and liquid separator has the characteristics of reasonable design, high structure strength, convenience in operation, complete solid and liquid separation, high separation efficiency, convenience in cleaning, long service life, log maintenance frequency, high reliability, strong practicality and the like, and is beneficial for greatly increasing production benefit of enterprises.

Owner:四川宝凯鑫诚环保科技有限公司

Pull-down device of computerized flat knitting machine

The invention discloses a pull-down device of a computerized flat knitting machine. The pull-down device comprises a left traction mechanism and a right traction mechanism which are symmetrically arranged and form a traction channel therebetween, and is characterized in that each of the left traction mechanism and the right traction mechanism comprises a plate frame, a guide assembly, a traction rake and a driving assembly, wherein a window is formed in the plate frame; the traction rake is installed on the back face of the plate frame in an up-down movable mode through the guide assembly, anda rake nail assembly is arranged on the side wall of the front face of the head of the traction rake and corresponds to the window; the driving assembly is installed on the back face of the plate frame and connected with the tail of the traction rake so as to drive the traction rake to move up and down along a guide track of the guide assembly, the rake nail assembly is guided to the outer side of the plate frame through the guide track when the traction rake moves downwards, and the rake nail assembly is guided to the inner side of the plate frame through the guide track when the traction rake moves upwards. According to the pull-down device, fabric can be uniformly and stably pulled, so that the processing efficiency and quality are improved.

Owner:无锡斯拓纺织科技有限公司

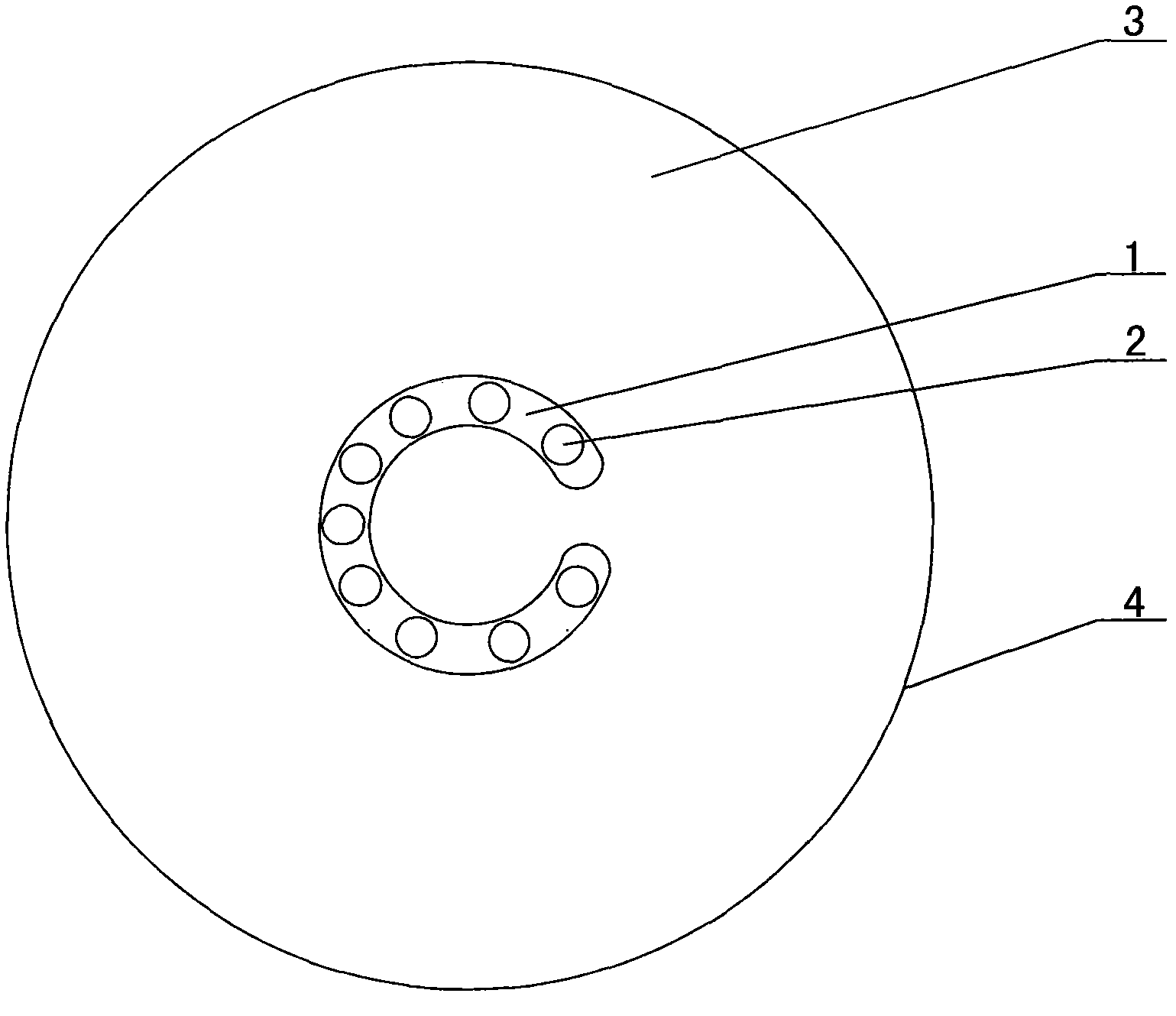

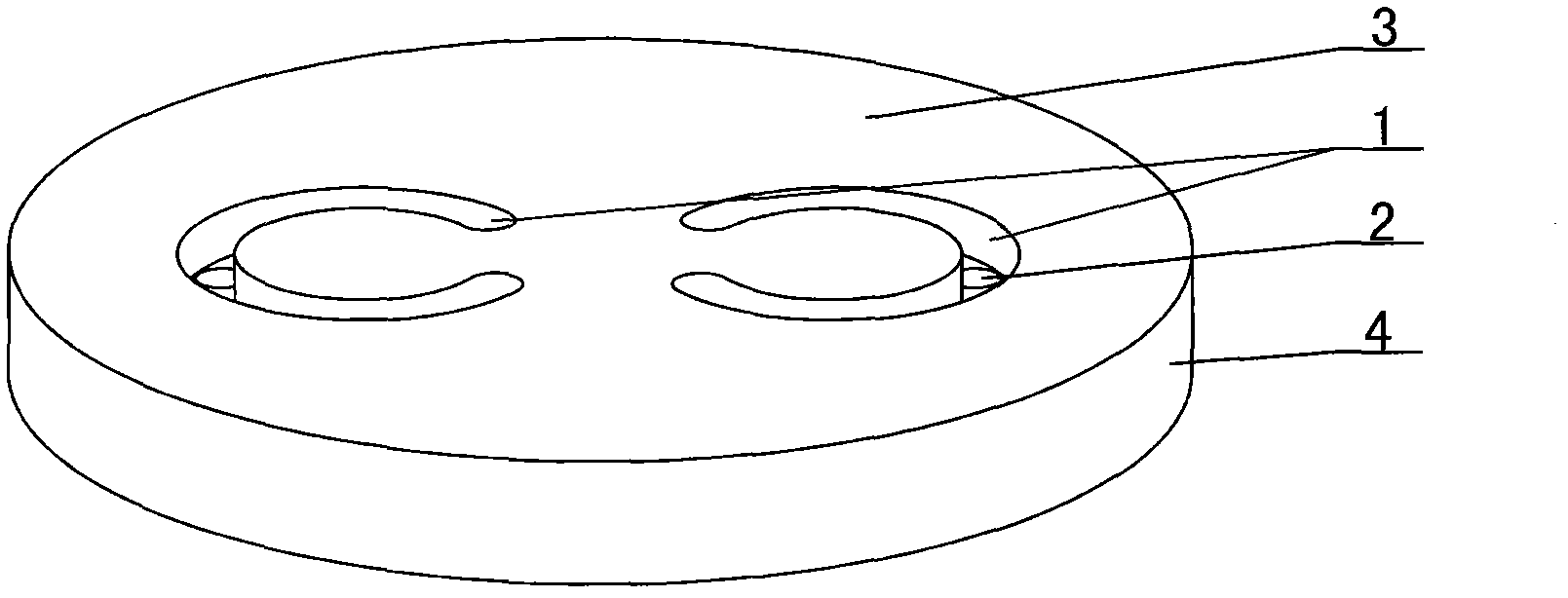

Drawing die plate for C-shaped silicon core

InactiveCN103160915APull to achieveFantastic ideaPolycrystalline material growthBy pulling from meltEngineeringSeed crystal

The invention discloses a drawing die plate for a C-shaped silicon core, and relates to a die plate. The drawing die plate for a C-shaped silicon core comprises a die plate (4) and a C-shaped groove (1), wherein the C-shaped groove is formed in the die plate, and a crystal solution passage penetrating to the bottom of the die plate (4) is formed in the bottom of the C-shaped groove (1); and the drawing die plate for a C-shaped silicon core disclosed by the invention is used for realizing drawing for the C-shaped silicon core by forming the C-shaped groove in the die plate, enabling the melted crystal solution to enter in the C-shaped groove, and then pulling out the C-shaped silicon core via C-shaped seed crystal. The drawing die plate for the C-shaped silicon core disclosed by the invention is wonderful in conception, simple in structure, and low in use cost; the later-stage use effect of the C-shaped silicon core is superior to the later-stage use effect of the existing cylindrical solid silicon core; and the speed of growing a polycrystalline rod by the C-shaped silicon core is far faster than the speed of growing a polycrystalline rod by the cylindrical solid silicon core. The drawing die plate for the C-shaped silicon core has certain market and application prospects.

Owner:LUOYANG JINNUO MECHANICAL ENG

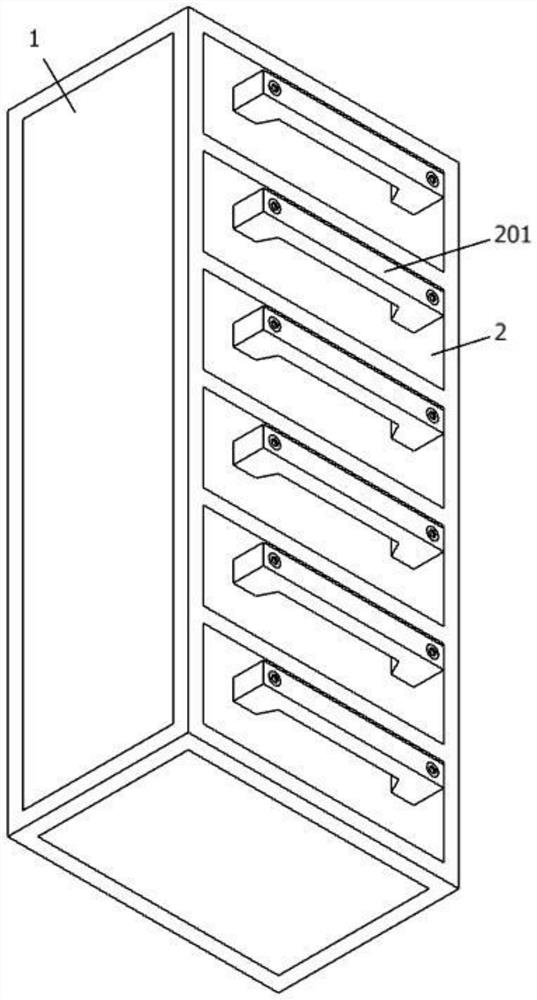

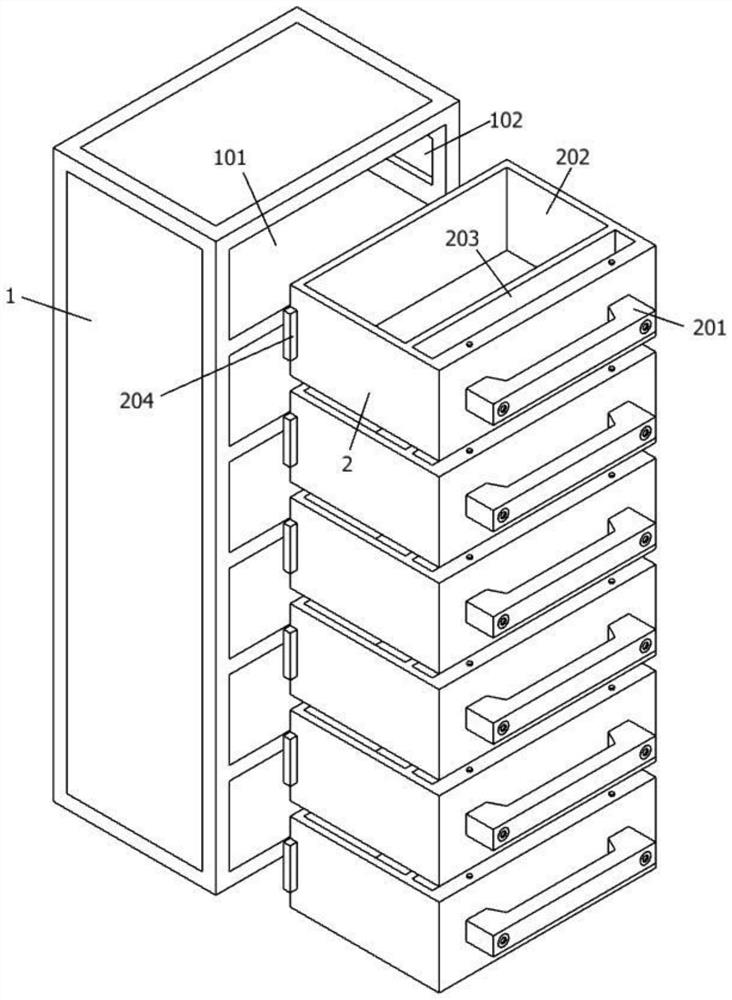

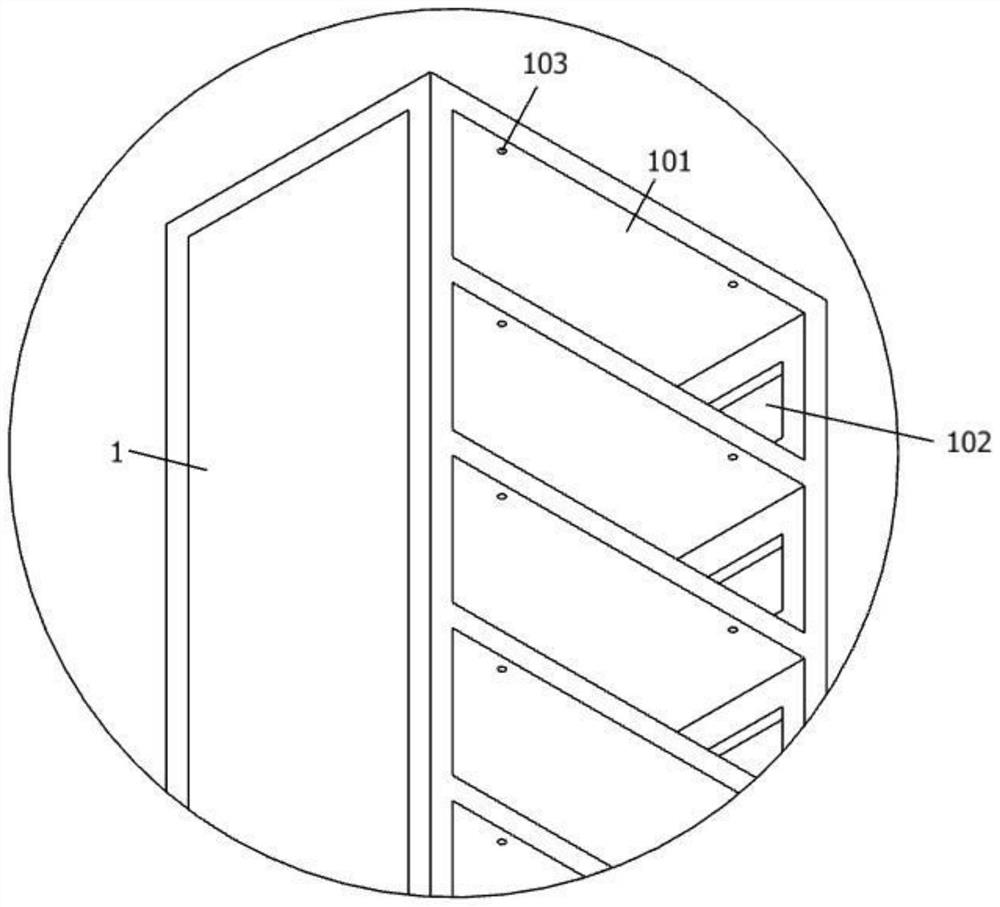

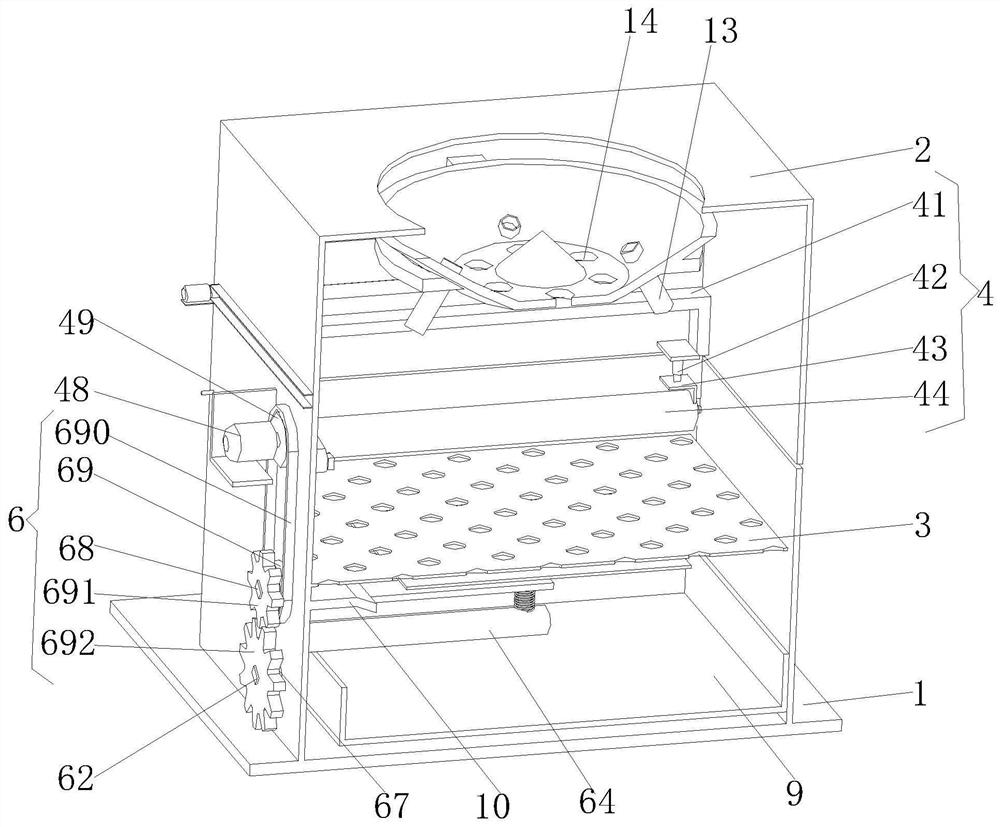

Land space planning result archive management and storage device

PendingCN114568843AAvoiding theft of archives and materials of land and space planning results in storage slotsReduced chance of grabbing handle structure settingsBook cabinetsChestsIndustrial engineeringFile management

The invention provides a territorial space planning result file management and storage device, and relates to the technical field of file management and storage, the territorial space planning result file management and storage device comprises a cabinet body, the front end face of the cabinet body is provided with six drawing grooves at equal intervals, and each drawing groove is internally slidably provided with a drawing type storage shell matched with the drawing groove in structure; in a daily storage state, the push-pull type storage shell used for storing files and the push-pull groove of the cabinet body are limited through insertion matching of the limiting plug pin and the limiting slot, and the push-pull type storage shell cannot be pulled; therefore, the situation that non-staff who do not clearly know the correct opening mode steal the territorial space planning result archive data in the storage groove is effectively avoided, and the problems that the archive data in an existing archive cabinet is protected through a lock, but the lock is not high in protection performance, the opening mode is too simple, and the lock cannot be opened easily are solved. And the file cabinet is easy to open without a key, so that file data in the file cabinet are leaked.

Owner:董菲

Pull-down opening and closing structure of computerized flat knitting machine

InactiveCN111979639APull to achieveSimple organizationWeft knittingEngineeringStructural engineering

The invention discloses a pull-down opening and closing structure of a computerized flat knitting machine. The structure comprises an opening and closing device and a rake type pull-down device. The opening and closing device comprises a front plate frame and a rear plate frame which are symmetrical left and right, wherein a pulling channel is formed between the front plate frame and the rear plate frame, and windows are arranged on the front plate frame and the rear plate frame; swing driving assemblies are connected to the front plate frame and the rear plate frame; the rake pull-down devicecomprises a left pulling mechanism and a right pulling mechanism, each of the left pulling mechanism and the right pulling mechanism comprises a guide assembly, a pulling rake and a pulling driving assembly; the pulling rakes are installed on the back of the front plate frame or the rear plate frame through the guide assemblies, and rake nail assemblies are arranged on the front side walls of thehead of the pulling rakes; and the pulling driving assemblies are connected with the tails of the pulling rakes. The mechanism is based on stable pulling of fabric, and has the characteristics of simple structure, simple operation and low cost.

Owner:无锡斯拓纺织科技有限公司

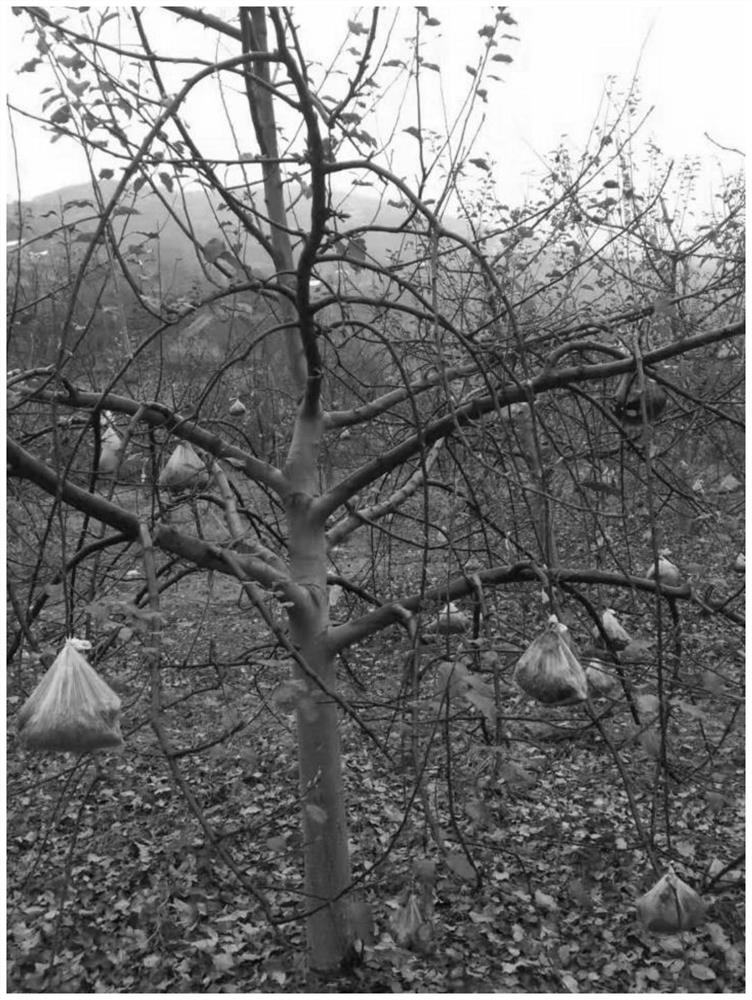

Economical and efficient apple tree branch stretching method

The invention discloses an economical and efficient apple tree branch stretching method. The method includes the following steps of firstly, concentratedly containing soil with plastic bags, wherein 0.3-1 g of soil is contained in each bag, and the soil containing bags are formed for use; secondly, determining the hanging parts of branches according to the ages and thicknesses of the branches, andhanging the soil containing bags on the hanging parts for branch stretching, wherein according to the method of determining the hanging parts and the soil containing bags, the hanging parts of the branches which are one year old or have the thickness of 0.7-1.0 cm are 15-20 cm above base parts of the branches, and each soil containing bag contains 0.3-0.4 g of soil; the hanging parts of the branches which are two years old or have the thickness of 1.1-1.3 cm are 30-35 cm above the base parts of the branches, and each soil containing bag contains 0.5-0.6 g of soil; the hanging parts of the branches which are three years old or have the thickness of 1.4-1.6 cm are 50-60 cm above the base parts of the branches, and each soil containing bag contains 0.9-1 g of soil. Materials are easy to use,cost is low, the soil containing bags can be recycled multiple times, operation is simple and convenient, time and labor are saved, no branches are injured, and the method is suitable for hanging andbranch stretching of main branches, side branches and fruiting branch groups of fruit producing and culturing trees of various shapes and high in adaptability.

Owner:INST OF FRUIT & FLORICULTURE RES GANSU ACADEMY OF AGRI SCI

Sewage sludge treatment method

InactiveCN104098239BAchieve dryingRealize step-by-step processingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFreeze-dryingSewage

The invention discloses a sewage sludge treatment method. The sewage sludge treatment method comprises a first step of utilizing a freeze drying energy circulating system to continuously freeze sludge in a sludge freezing container, unfreezing the sludge after continuous freezing, and performing freezing and unfreezing repeatedly; a second step of dehydrating the sludge having undergone freezing and unfreezing treatment in a filter pressing device, wherein dehydration comprises a filter pressing stage and a squeezing dewatering stage, and enabling the sludge to undergo filter pressing to be chunk mud-cake-shaped sludge low in moisture content; a third step of crushing the chunk mud-cake-shaped sludge in a crushing device and forming small sludge particles; a fourth step of conveying the crushed sludge particles to enter a sludge drying device to be dried, enabling the freeze drying energy circulating system to release heat through a condenser, transferring heat to air, and enabling the hot air to enter the sludge drying device to dry the sludge particles. According to the sewage sludge treatment method, chemical agents do not need to be added to sludge, the sludge treatment amount is not increased in the treatment process, and recycling of working medium energy greatly improves sludge freezing efficiency and heat utilization rate.

Owner:CHINA JILIANG UNIV

Energy-saving sewage sludge harmless treatment method

InactiveCN104140188BAchieve dryingDoes not increase throughputSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeFreeze-drying

The invention discloses an energy-saving type sewage sludge harmless treatment method. The method includes the following steps of firstly, conducting continuous freezing on sludge through a freeze drying energy circulation system, and unfreezing the sludge after continuous freezing; secondly, conducting dewatering on the sludge, completely processed through freezing and unfreezing, in a filter pressing device, so that sludge with the low moisture content is obtained through filter pressing; thirdly, smashing the sludge in a smashing device; fourthly, conveying smashed sludge particles into a sludge drying device to be dried, dissipating heat through the freeze drying energy circulation system by means of a condenser, and transferring heat to air; fifthly, sending the sludge particles into an incinerator to be incinerated, making generated high-temperature smoke enter a waste heat boiler, making air heated by the condenser enter a second heat exchanger to continue to absorb heat, and unfreezing the sludge and drying the sludge particles through the formed high-temperature air. By means of the method, the sludge processing amount cannot be increased in the treatment process, and due to recycling of working medium energy, the freezing efficiency and the heat utilization rate of the sludge are increased.

Owner:CHINA JILIANG UNIV

Pull-down device of computerized flat knitting machine

The invention discloses a pull-down device of a computerized flat knitting machine. The pull-down device comprises a left traction mechanism and a right traction mechanism which are symmetrically arranged and form a traction channel. The pull-down device is characterized in that each of the left traction mechanism and the right traction mechanism comprises a plate frame, a guide assembly, a traction rake and a driving assembly; a window is formed in each plate frame; the traction rakes are installed on the back faces of the plate frames in an up-down movable manner through the guide assemblies, and a rake nail assembly is arranged on the side wall of the front face of the head of each traction rake and corresponds to the corresponding window; and the driving assemblies are installed on theback faces of the plate frames and connected with the tails of the traction rakes so as to drive the traction rakes to move up and down along the guide tracks of the guide assemblies, the rake nail assemblies are guided to the outer sides of the plate frames through the guide tracks when the traction rakes move downwards, and the rake nail assemblies are guided to the inner sides of the plate frames through the guide tracks when the traction rakes move upwards. According to the pull-down device, fabric can be uniformly and stably pulled, so that the processing efficiency and quality are improved.

Owner:无锡斯拓纺织科技有限公司

Medical disposable rubber glove centralized treatment system

InactiveCN113070268ARealize splittingEasy to rinseCleaning using liquidsElectric machineryTreatment system

The invention relates to a medical disposable rubber glove centralized treatment system. The medical disposable rubber glove centralized treatment system comprises a base, an operation box, an elastic plate, a pulling device, a flushing device, a vibration device and a centralized push-out device. According to the medical disposable rubber glove centralized treatment system, by starting a reciprocating motor, the output end of the reciprocating motor drives a pulling shaft to rotate, so that disposable medical gloves on the elastic plate are pulled open by the aid of the elastic plate; and a hydraulic rod is lengthened until a pulling roller makes contact with the gloves, so that the gloves accumulated at different heights are open, and the gloves are fully flushed; and by adopting the flushing device, a steering motor is started, the output end of the steering motor drives a washing rod at the rear side to rotate, the washing rod at the rear side rotates to drive chain wheels to rotate, and finally two washing plates move face to face or relatively to achieve opposite washing of the gloves in the operation box at different angles, so that the glove cleaning effect is better.

Owner:赵亚伟

Drag device and drag method of tunnel internal shield main engine

Owner:齐鲁交通发展集团有限公司 +1

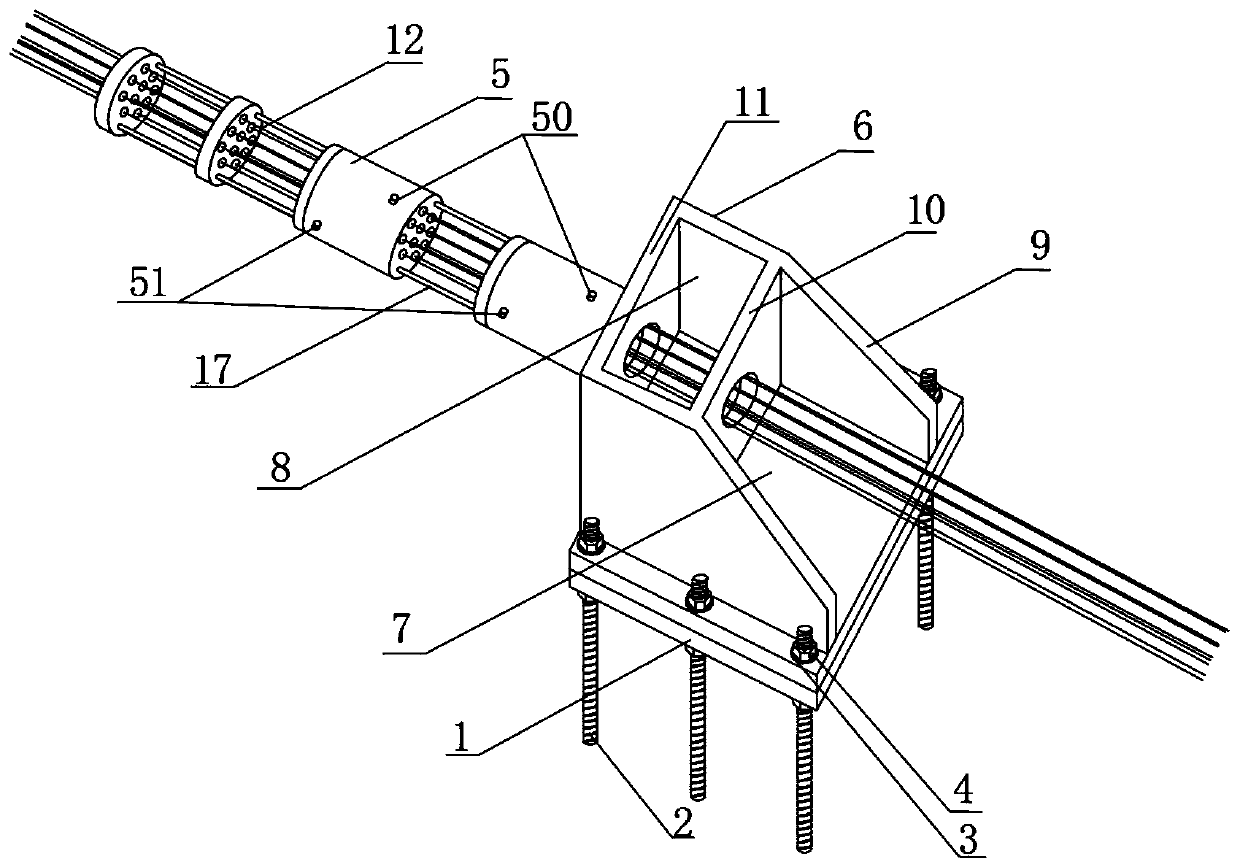

Power cable tensioning device

InactiveCN105314461AEasy to clamp and solidifyPull to achieveFilament handlingPower cableEngineering

A power cable tensioning device comprises a clamping hoop. An external thread is arranged on the outer side of the clamping hoop, and a clamping nut is arranged in cooperation with the outer wall of the clamping hoop. The clamping nut is composed of two semi-rings, wherein the side of each semi-ring is provided with a convex head and a concave groove, and the convex heads are matched with the concave grooves. A hanging hole is formed in the outer side of each semi-ring, and a traction rope is arranged in each hanging hole correspondingly. The power cable tensioning device further comprises a support. The lower side of the support is hinged to a base. The two sides of the upper end of the support are each provided with a hanging ring. Each hanging ring comprises an upper roller and a lower roller. Stop rods are arranged on the two sides of each lower roller. The traction ropes wind across the upper rollers and the lower rollers and then are provided with a tray. Cylindrical pressing blocks are borne on the tray. A through groove is formed in each pressing block in the radial direction of the pressing block. Each pressing block is provided with a bent groove. The tail end of each bent groove is communicated with the tail end of the inner side of the corresponding through groove. A telescopic device is arranged on the base, one end of the telescopic device is fixed on the base, and the other end of the telescopic device is hinged to the support.

Owner:STATE GRID CORP OF CHINA +1

A Cost-Effective Method for Pulling Branches of Apple Trees

ActiveCN109566144BPull to achieveOvercoming susceptibility to strangulationHorticulture methodsTree shapedAgronomy

The invention discloses an economical and high-efficiency apple tree branching method, which comprises the following steps: (1) Concentrating on carrying out plastic bags to store soil, each bag containing 0.3-1 catties of soil, forming soil bags for use; (2) According to the age of the branches 1. The degree of thickness determines the hanging position of the branch, and the hanging position is wrapped with the described soil bag to pull the branches. The determination method of the hanging position and the soil bag is: annual or branches with a thickness of 0.7-1.0cm, the hanging position At a distance of 15-20cm from the base of the branch, the soil bag is 0.3-0.4 catties of soil; for biennial branches or branches with a thickness of 1.1-1.3 cm, the hanging part is at a distance of 30-35 cm from the base of the branch, and the soil bag is 0.5-0.6 catties of soil; three-year-old Or branches with a thickness of 1.4-1.6cm, the hanging part is 50-60cm away from the base of the branch, and the soil bag is filled with 0.9-1 catties of soil. The invention is easy to obtain materials, low in cost, the soil bag can be recycled and used for many times, easy to operate, saves time and labor, does not damage the branches, and is suitable for hanging and pulling the main branches, side branches and fruiting branches of various tree shapes in apple production and cultivation. Branches, wide adaptability.

Owner:INST OF FRUIT & FLORICULTURE RES GANSU ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com