Full-automatic bamboo cane feeding device

A feeding device, fully automatic technology, applied in workpiece feeding devices, processing machines for manufacturing flat surfaces, wood processing appliances, etc. High degree of automation, avoid feeding jam, and improve the accuracy of recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

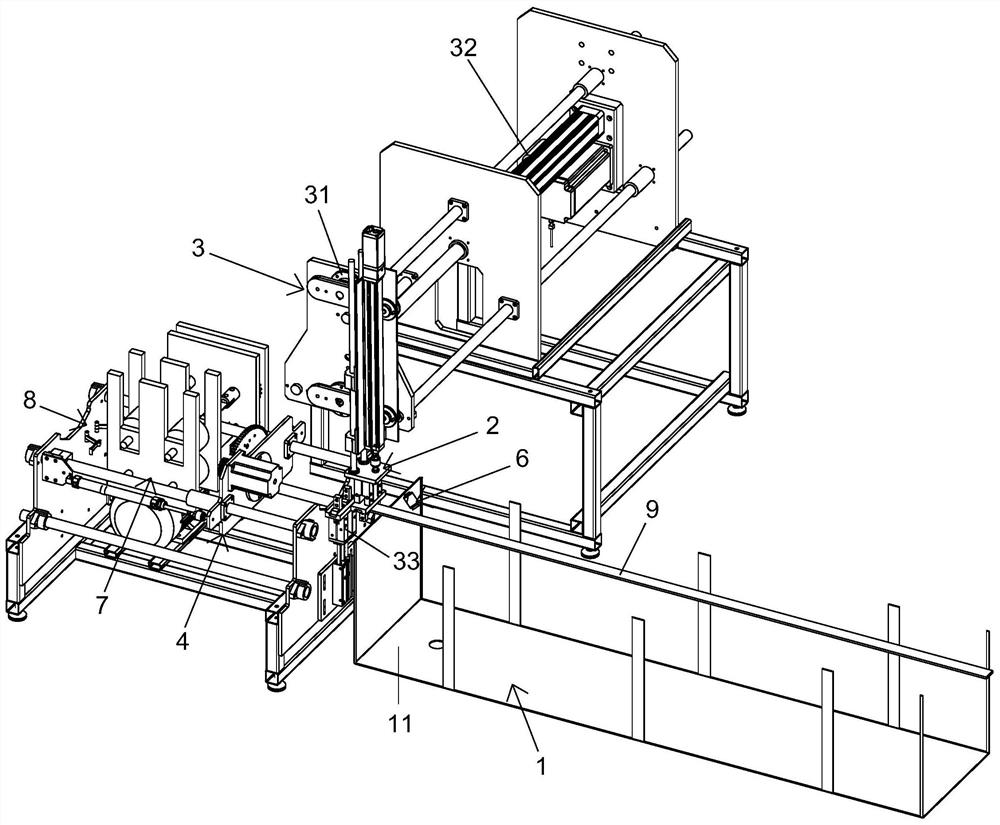

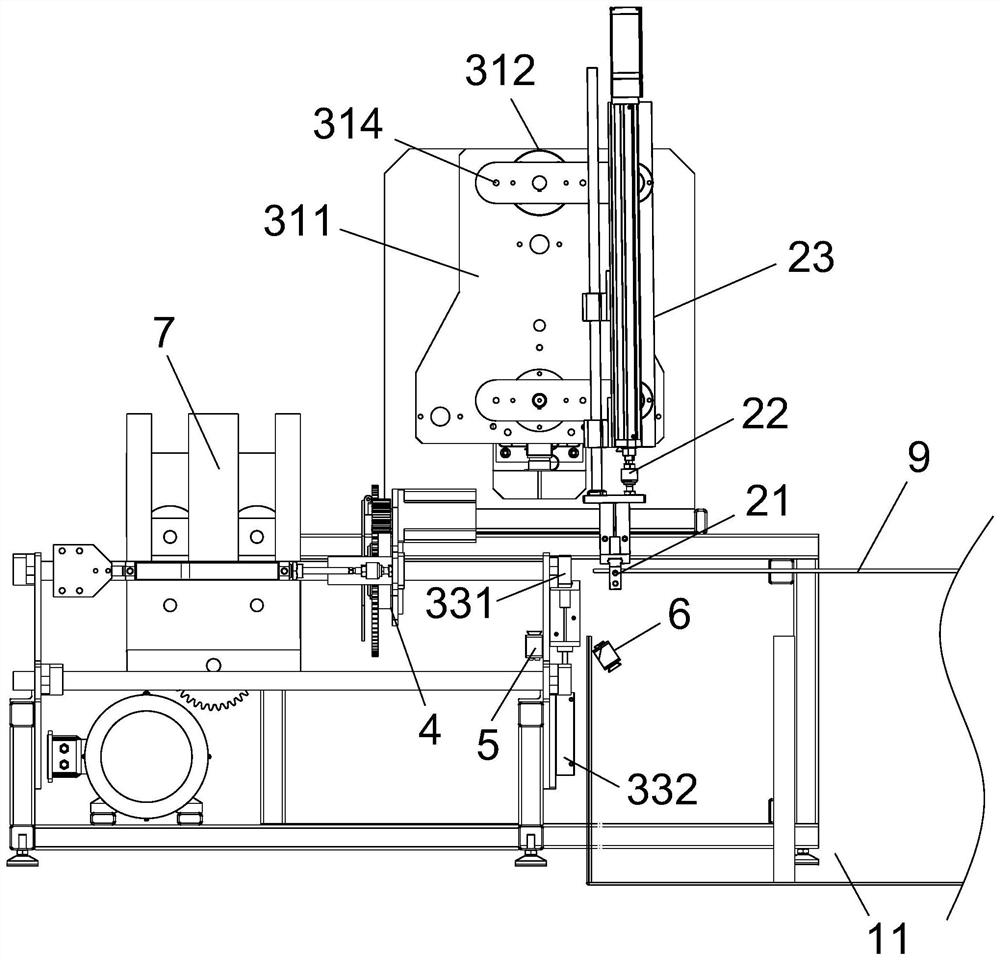

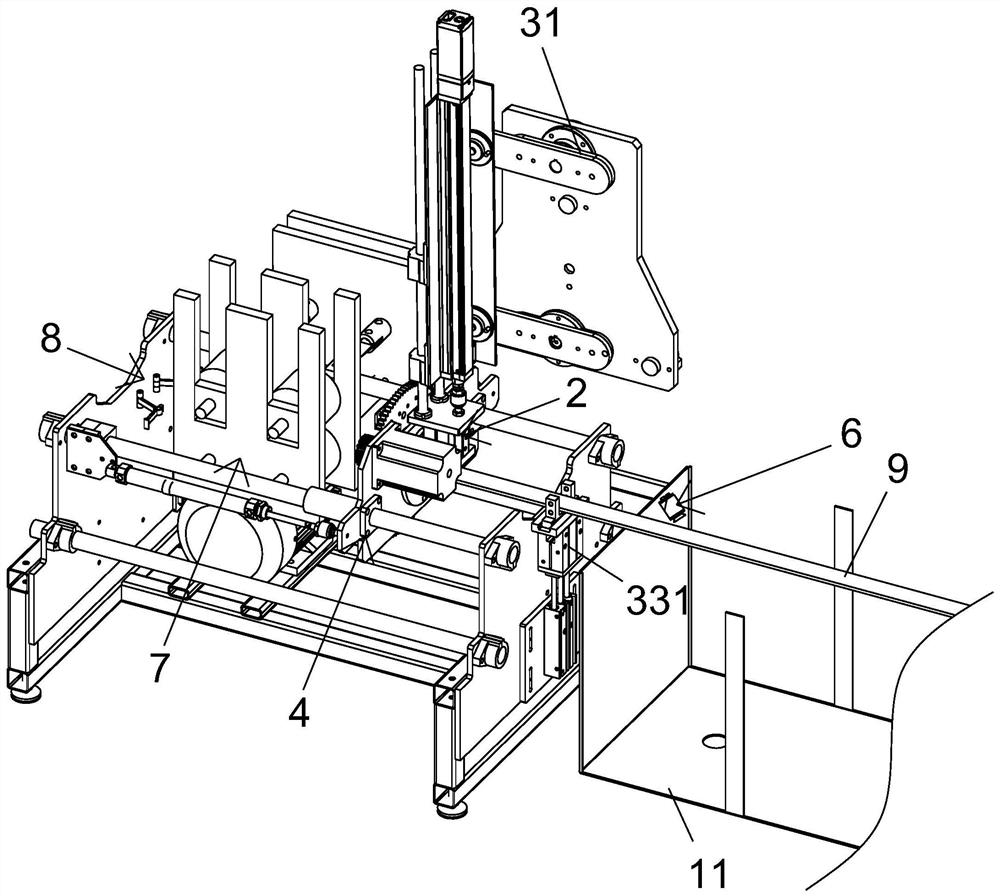

[0027] Such as Figures 1 to 11 Shown is a schematic diagram of an embodiment of a fully automatic bamboo stick feeding device provided by the present invention.

[0028] A fully automatic bamboo strip feeding device, which includes a feeding mechanism 1, a grasping mechanism 2, a feeding mechanism 3 and a pulling mechanism 4;

[0029] The feeding mechanism 1 includes a feeding frame 11 for stacking bamboo strips. The bamboo strips in the feeding frame 11 are extended forward and backward, and the front ends of the bamboo strips lean against the front baffle plate of the feeding frame.

[0030] The front side of the feeding frame can be inclined downwards, and a vibrating part is arranged on it.

[0031] The grasping mechanism 2 is arranged above the feeding frame 11, and it includes grasping parts 21 for clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com