Pulling device of knitting machine

A pulling device and mechanical technology, applied in knitting, weft knitting, warp knitting, etc., can solve problems such as poor control of pulling force, achieve the effect of ensuring quality and avoiding coil elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

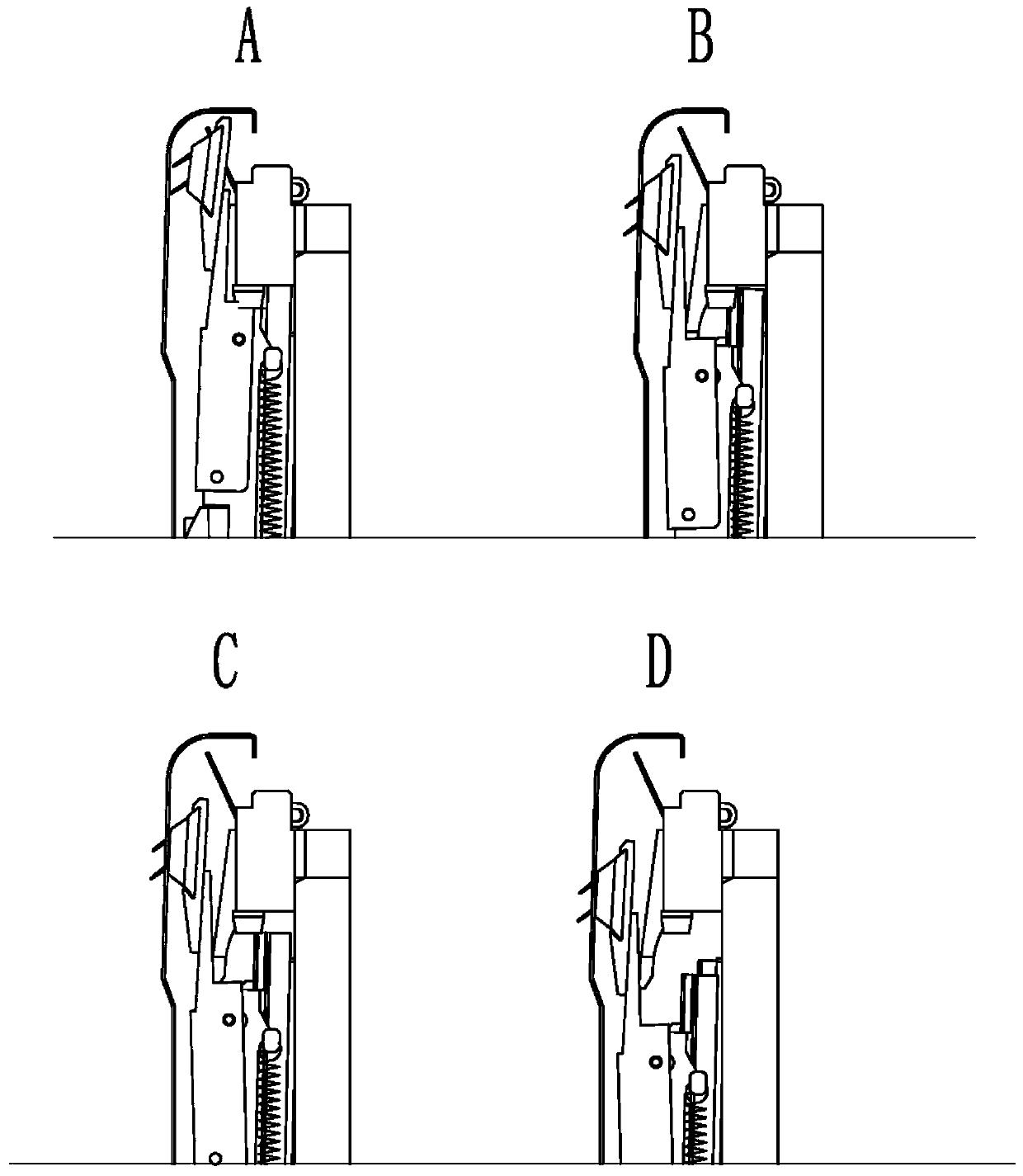

[0023] The specific embodiment of the specific solution of the present invention will be further elaborated in conjunction with the accompanying drawings.

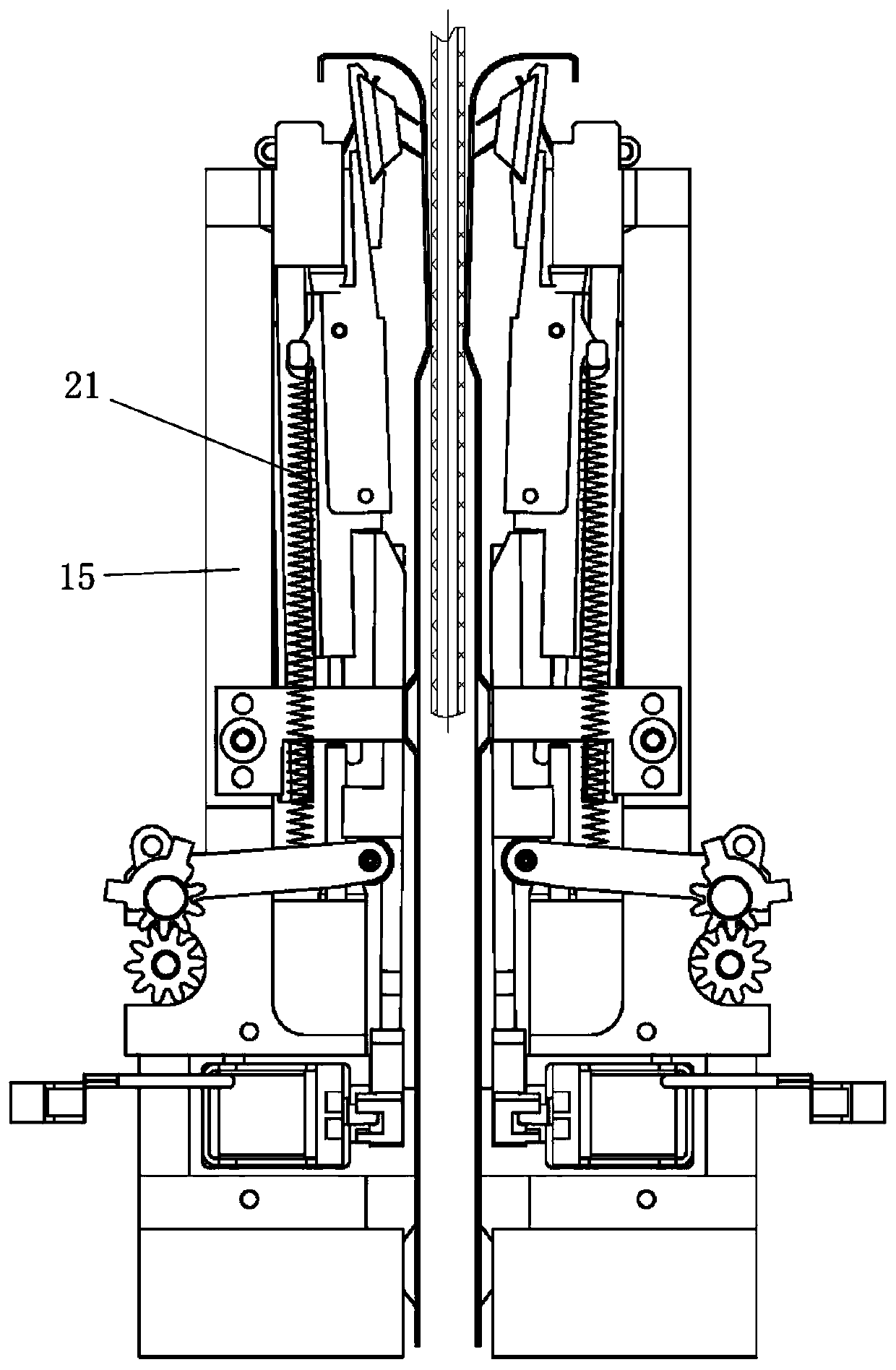

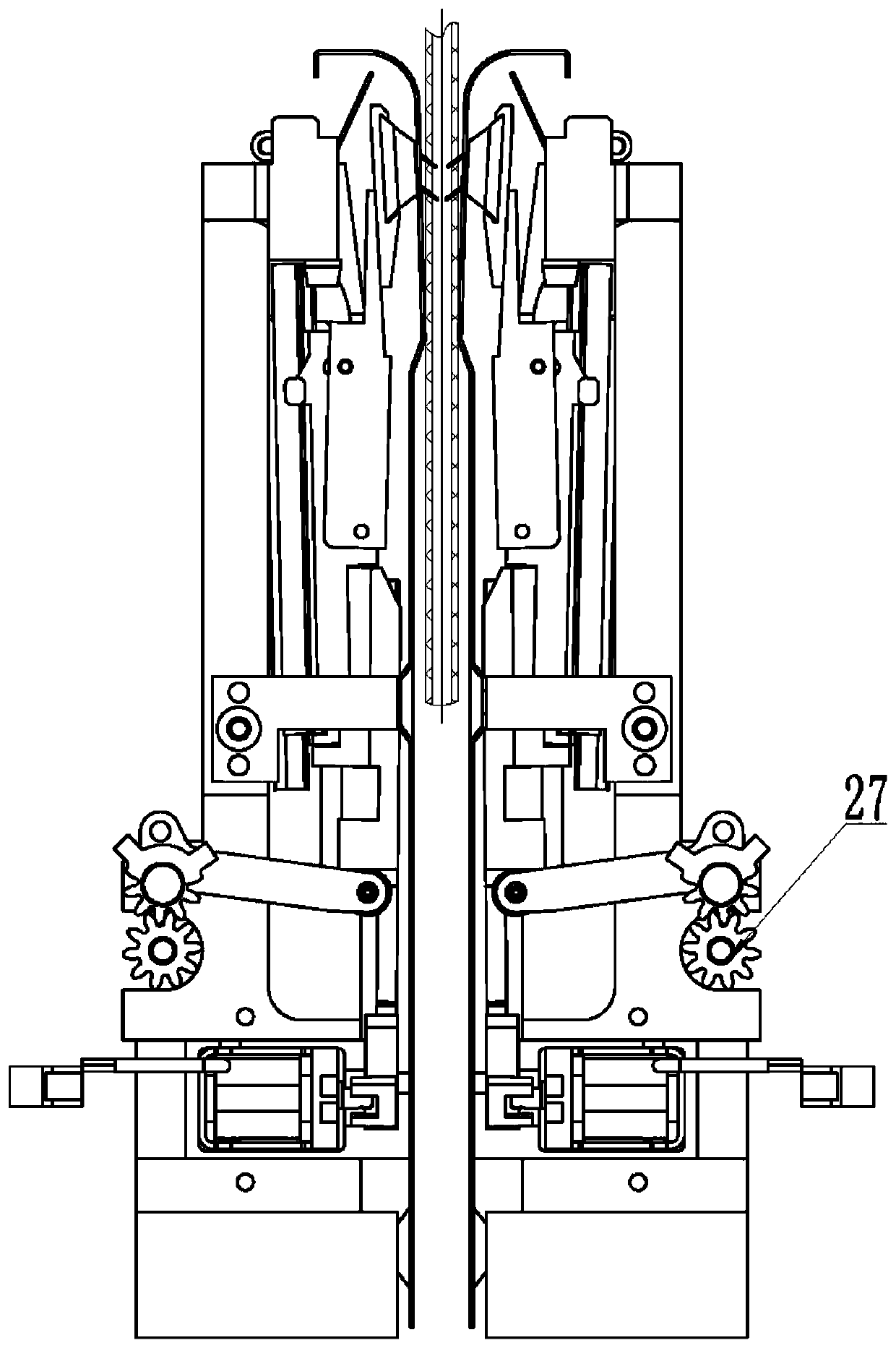

[0024] As shown in the figure, a pulling device of a knitting machine includes several rake-type pulling mechanisms, and each rake-type pulling mechanism includes a gripper seat 2, a gripper seat separation block 3, a lifting seat 5 and a fixed seat 15. Above the gripper seat 2, a gripper 4 is provided through the separation block 3 of the gripper seat. The front end of the gripper seat 2 is also provided with a guard plate 1, and the guard plate 1 is provided with a plurality of long shapes for the gripper 4 to move. The guard plate 1 is installed on the fixed seat 15 through the guard plate support, and the guard plate support includes the first guard plate support 14 and the second guard plate support 24, and the first guard plate support 14 and the second guard plate support 24 simultaneously hold the guard plate The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com