Traction device of knitting machine

A technology of a pulling device and a knitting machine, applied in knitting, weft knitting, warp knitting, etc., which can solve the problems of easy deformation of fabrics, loss of rubber layer, and inability to pull fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

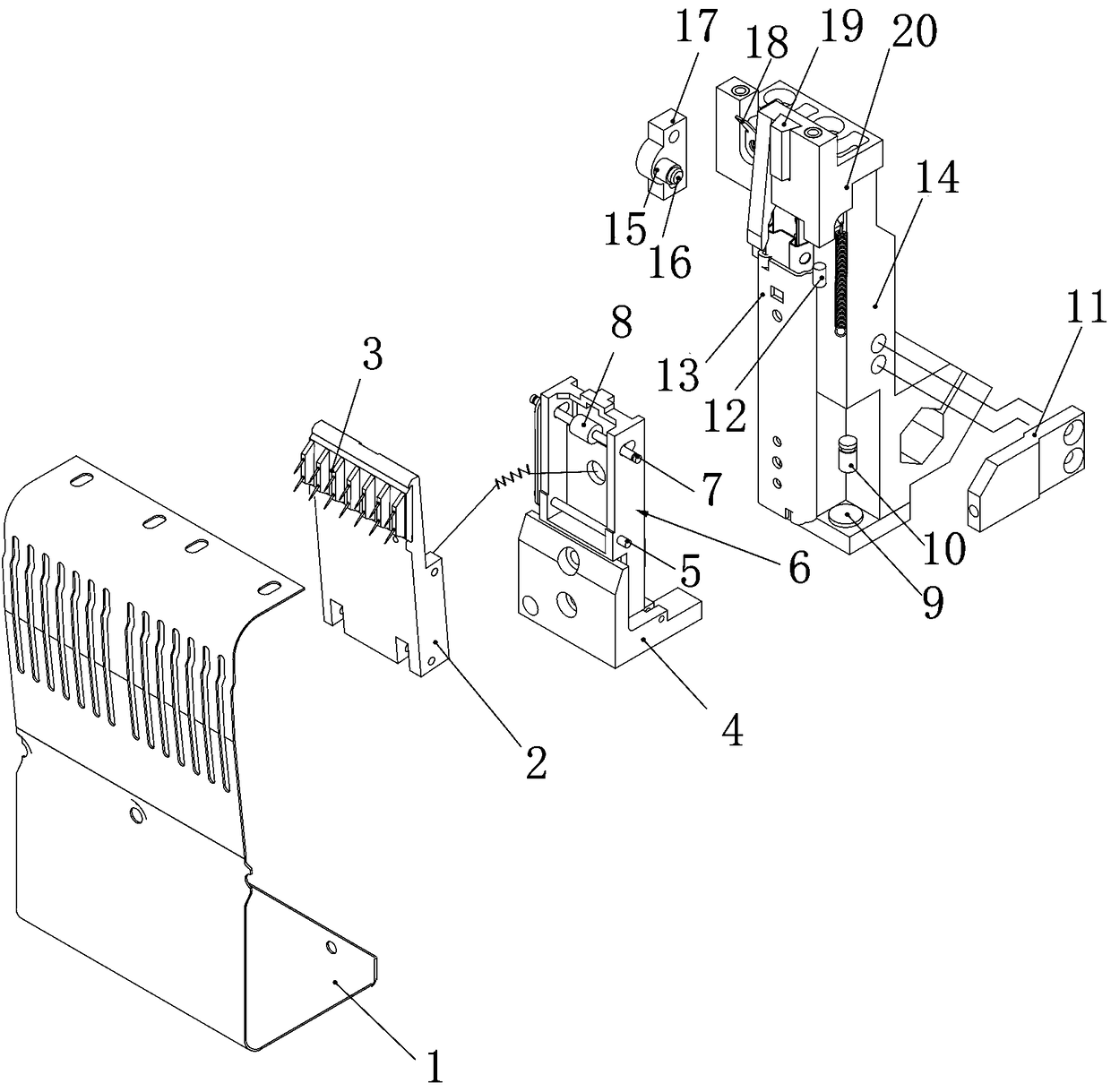

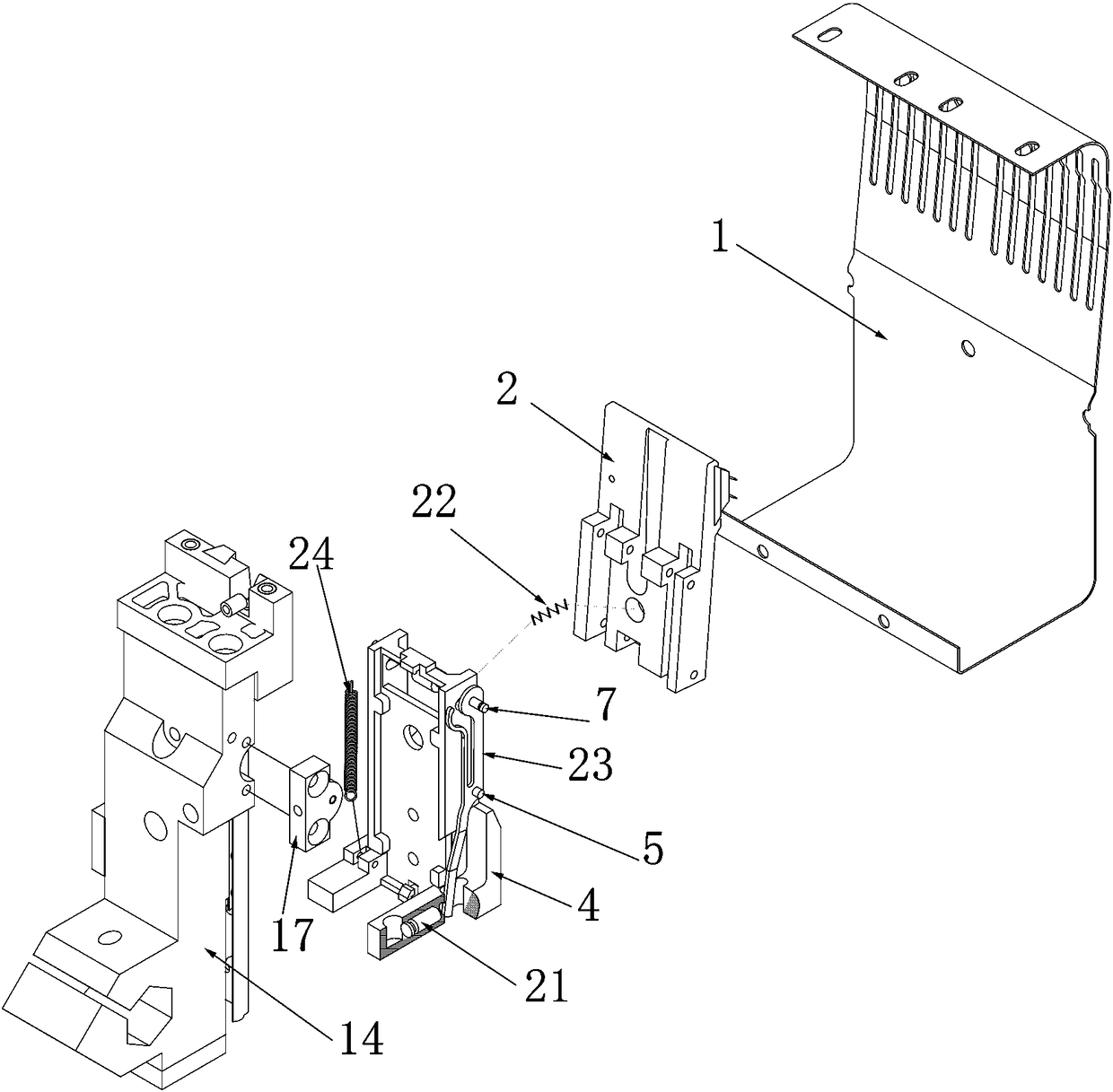

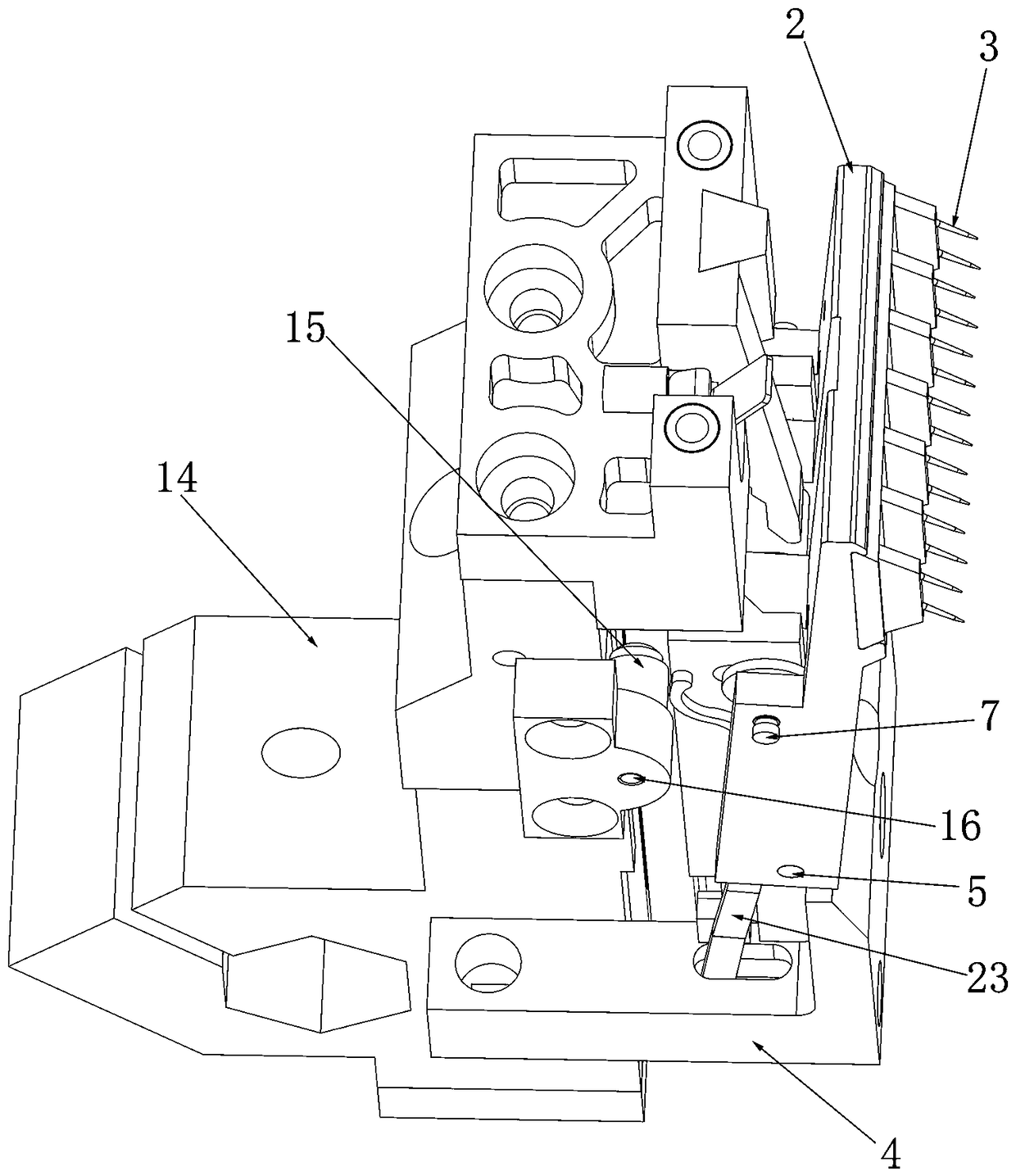

[0021] See attached picture. The pulling device of this embodiment is composed of several rake-type pulling mechanisms on both sides, and each rake-type pulling mechanism is independent, and some of the rake-type pulling mechanisms can be freely selected for action. Each rake-type pulling mechanism includes a claw seat 2, a lifting seat 4 and a fixed seat 14;

[0022] Above the front side of the gripper seat 2 is provided with a gripper 3 composed of several sheet needles, the gripper 3 can complete the pulling action without causing damage to the knitted fabric; the front end of the gripper seat 2 is also provided with a guard plate 1. There are several long grooves on the guard plate for the claws to move. The guard plate 1 is installed on the fixing seat 14 through the guard plate support 11 to protect the fabric and the claws. A linear bearing seat 6 is installed on the lifting seat 4, and the linear bearing seat 6 and the fixed seat 14 are connected by a linear bearing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com