Drawing die plate for C-shaped silicon core

A template and silicon core technology, which is applied in the field of drawing templates for C-shaped silicon cores, can solve the problems of increased fracture or collapse of silicon cores, large impact of cracks, and inability to grow silicon cores, achieving simple structure and low cost of use , Use the effect of excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

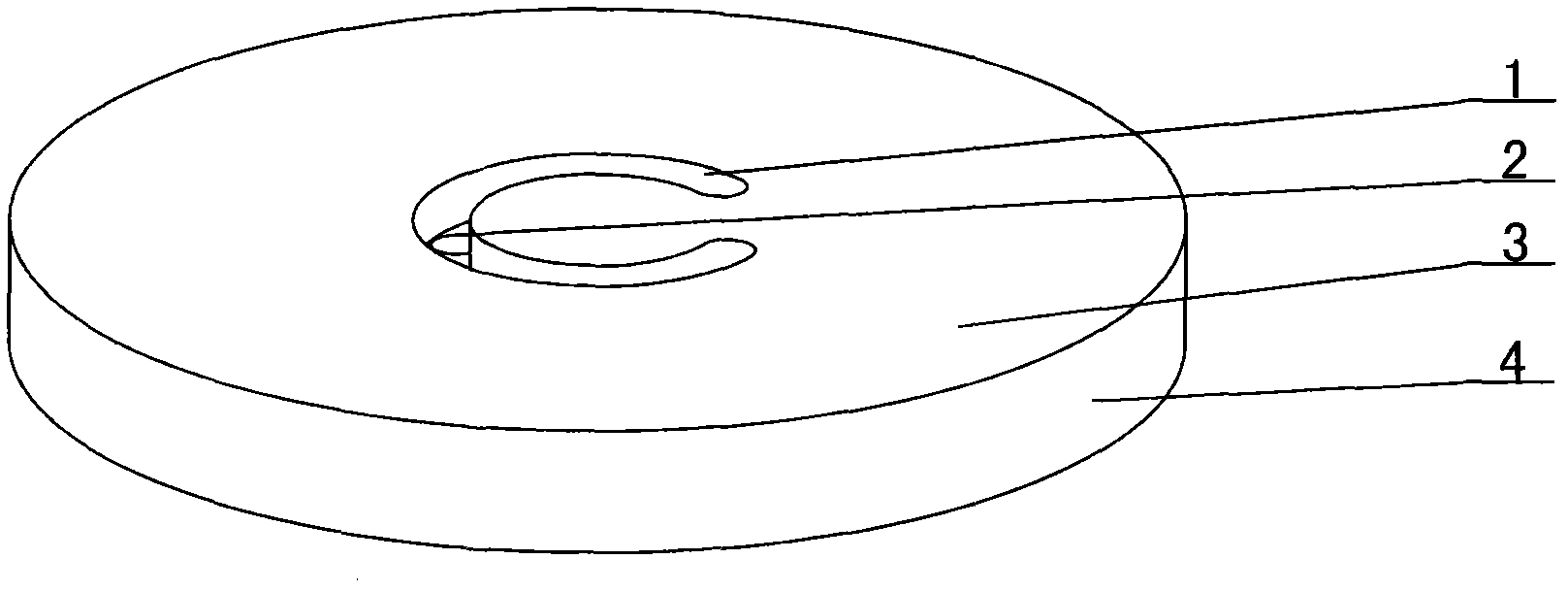

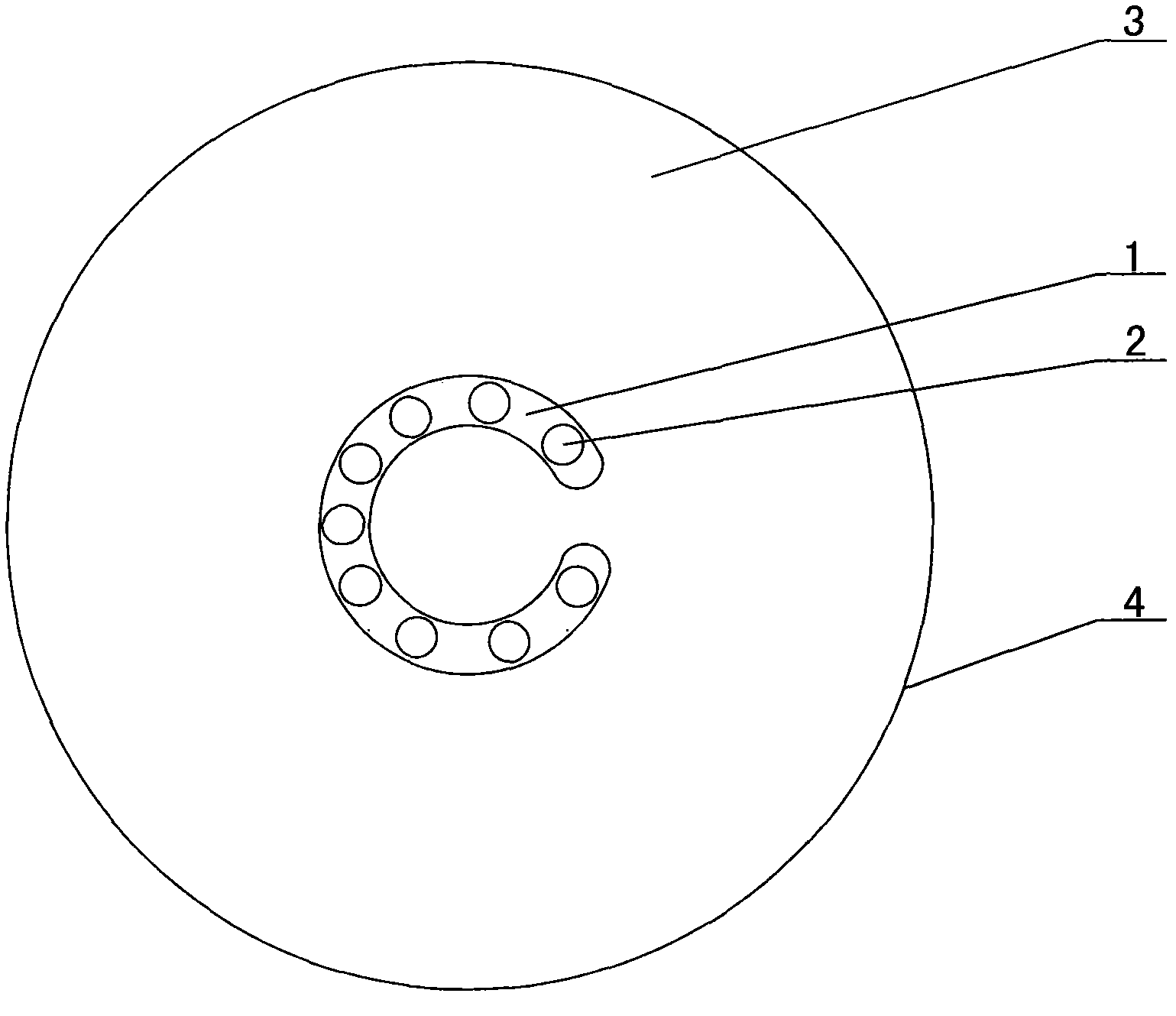

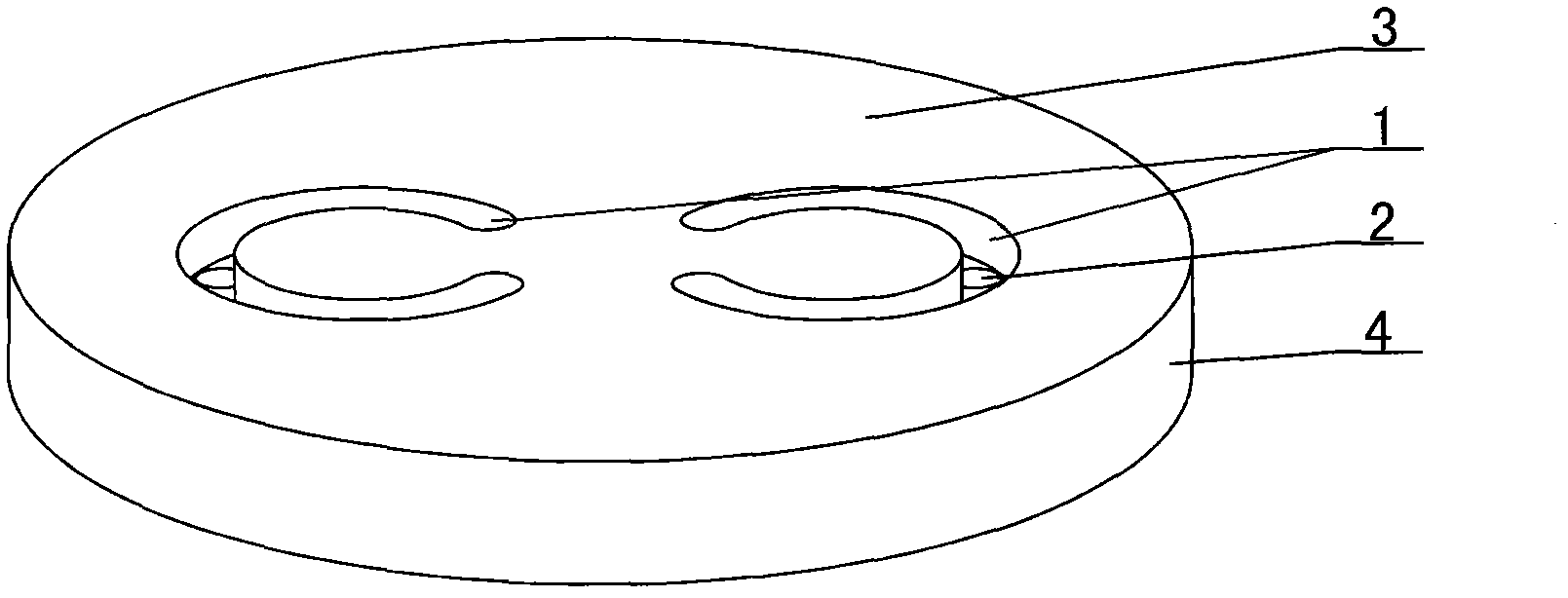

[0037] combined with Figure 1-10 The drawing template of the C-shaped silicon core described in includes a template 4 and a C-shaped groove 1, and a C-shaped groove is arranged on the template, and the bottom of the C-shaped groove 1 is provided with a liquid crystal passage through the bottom of the template 4 ; There is at least one C-shaped groove 1 provided on the template 4, and the bottom of the C-shaped groove is provided with a liquid crystal passage through to the bottom of the template 4; Groove 1, at the bottom of the C-shaped groove 1, a hole correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com