Threaded bolt with taper and its processing tooth plate

A thread and tooth plate technology, applied in the field of automotive fasteners, can solve problems such as the problem of sliding teeth, and achieve the effect of solving the problem of sliding teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

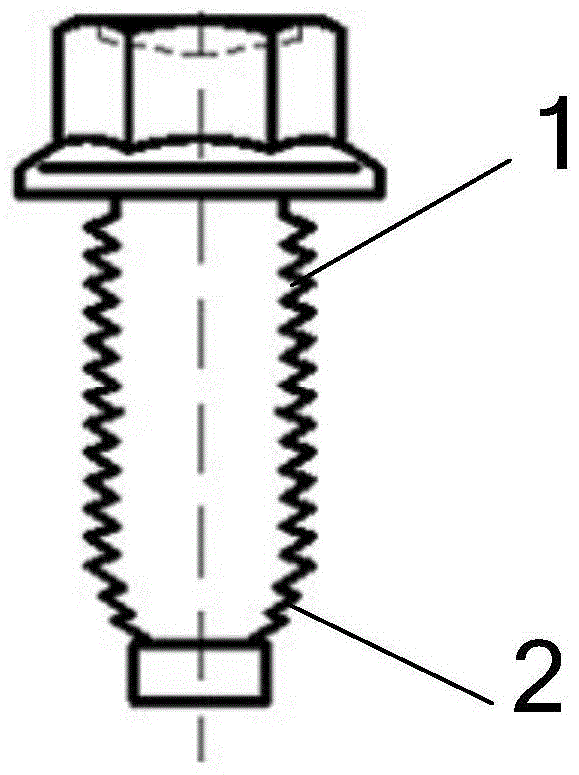

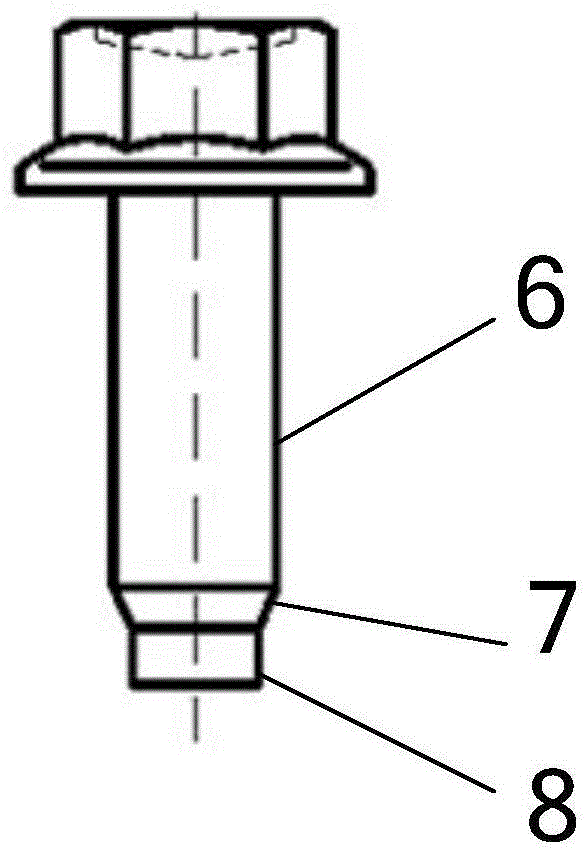

[0012] Such as figure 1 with 3 As shown, the threaded bolt with taper includes an integrally formed bolt head and bolt shank; the cylindrical surface of the bolt shank includes a matching cylindrical surface 6, a guiding cone surface 7 and a guiding cylindrical surface 8 from the head to the tail in sequence; the matching cylindrical surface is processed with Cooperating thread 1; guide thread 2 is processed on the guide cone surface; the pitch of the cooperating thread is equal to that of the guiding thread, and the lead angle of the guiding thread is 2 times larger than that of the mating thread.

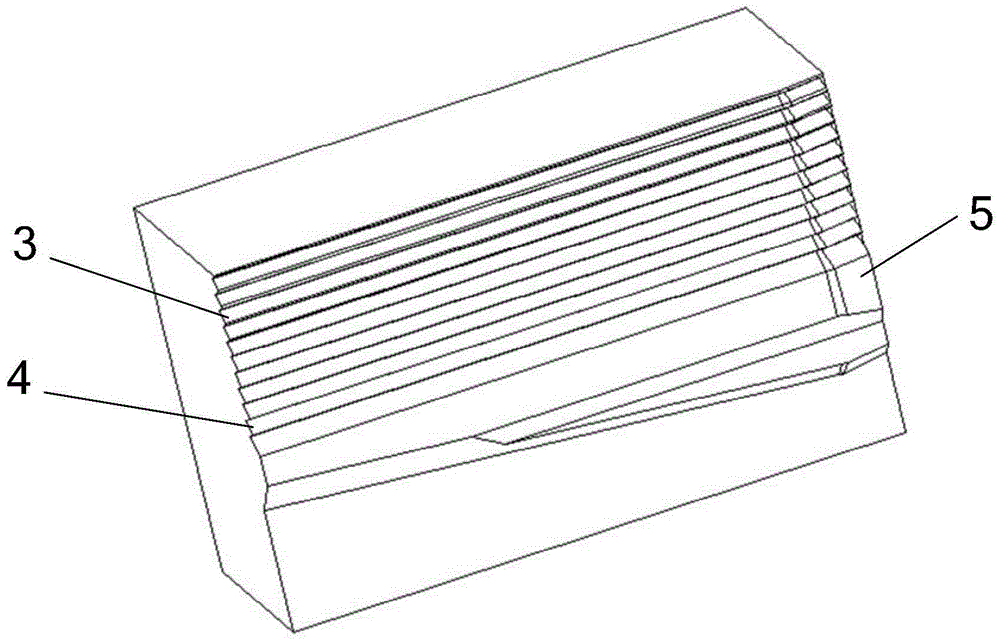

[0013] Such as figure 2 As shown, the tooth plate for processing threaded bolts with taper includes dynamic and static thread rolling plates; the inner sides of the dynamic and static thread rolling plates are processed with a plurality of cooperating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com