Steam cooking device

A technology of steam and equipment, applied in the field of steam cooking equipment, can solve the problems of energy loss, escape of hot air or steam, etc., and achieve the effect of simple structure and simple energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

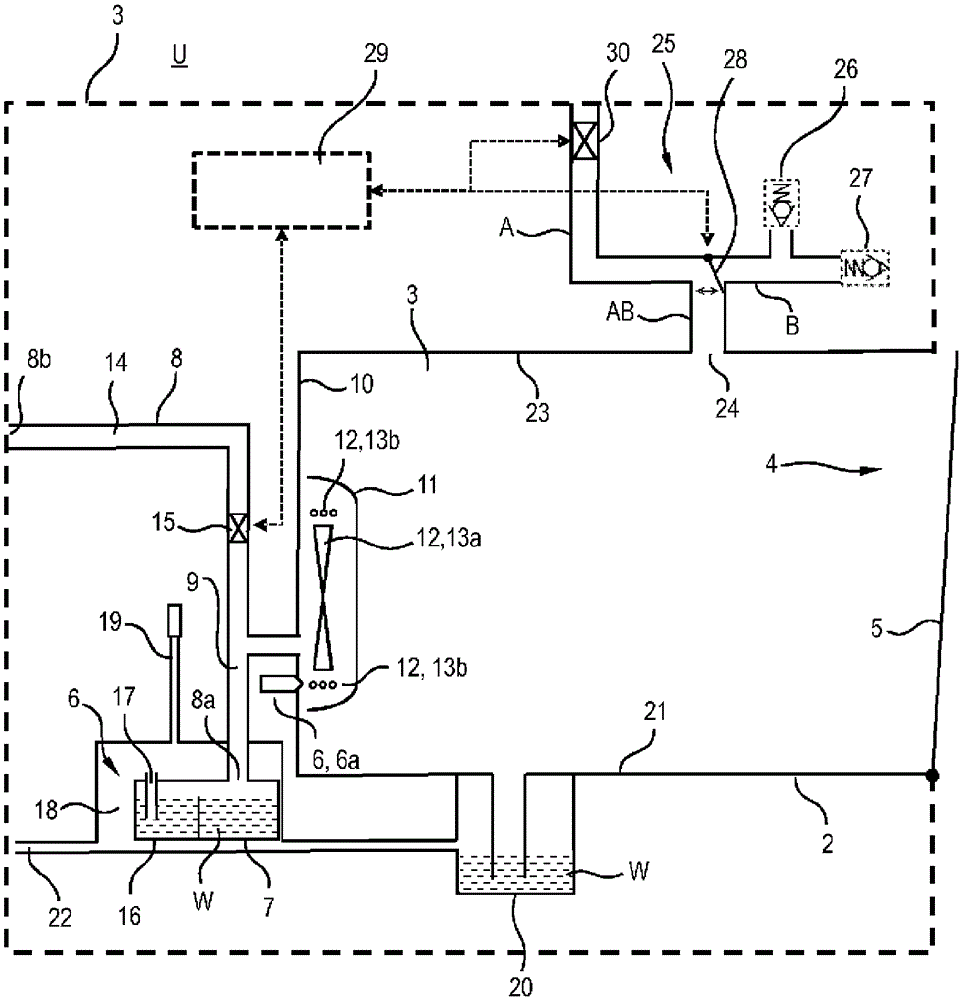

[0025] The figures show a side sectional view of a steam cooking device 1 with hot air or oven function. The steam cooking device 1 has a cooking chamber wall or cyclone 2 which surrounds a cooking chamber 3 . The cooking chamber 3 can be filled with food to be processed, for example through a front filling opening 4 , which can be closed with a door 5 . Arranged on the rear wall 10 of the cyclone furnace 2 is an impingement wall 11 (also referred to as an air deflector), which protects the circulating air heater 12 . The circulating air heater 12 has a fan 13 a and a heating ring 13 b surrounding this fan laterally. The cooking chamber 3 can additionally be heated by means of an upper heater and / or a lower heater. The steam cooking device 1 also has a steam generating unit 6 which, purely by way of example, has a spray head 6a for spraying water onto the heating ring 13b.

[0026] The steam pipe 8 leads into the rear wall 10 behind the collision wall 11 . The steam pipe 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com