Full-feed half-feed dual-purpose harvester multi-channel conveying header

A semi-feeding and harvester technology, applied in the direction of the header, harvester, application, etc., can solve the problems of grain falling off and complex structure, and achieve the effect of reducing the conveying link, small volume and reducing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

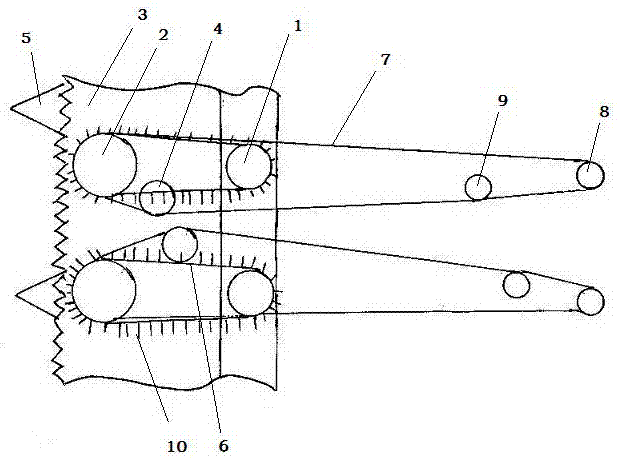

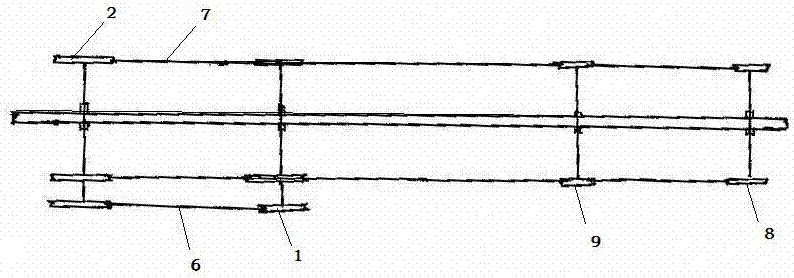

[0008] A full-feed and half-feed dual-purpose harvester multi-channel conveying header, including a support frame connected to the harvester body, a gear box 3 and a grain dividing plate 5 arranged at the end of the support frame, and a support frame arranged on the support frame. There are two upper and lower pulleys, and the two sets of pulleys are relatively arranged as a group. More than two sets form a multi-channel conveying header. The driving wheel 1 is connected to the transmission shaft of the gearbox 3, and both are powered by the power machine. The driving wheel 1 passes through the Fuhe belt 6 Connected with the front driven wheel 2, the grain-holding belt 6 is provided with a grain-holding tooth 10, and the distance between two sets of grain-holding belts 6 is small at the front and large at the rear, which facilitates the withdrawal of the straw. Conveyor belt 7 is connected with front tension pulley 4, rear tension pulley 9, rear driven wheel 8, and the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com