Copper pipe clamping tool of copper pipe punching machine

A technology for punching machines and copper pipes, which is applied in the direction of feeding devices, manufacturing tools, positioning devices, etc., can solve the problems of low efficiency and time-consuming clamping, and achieve the effects of high efficiency, good versatility, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

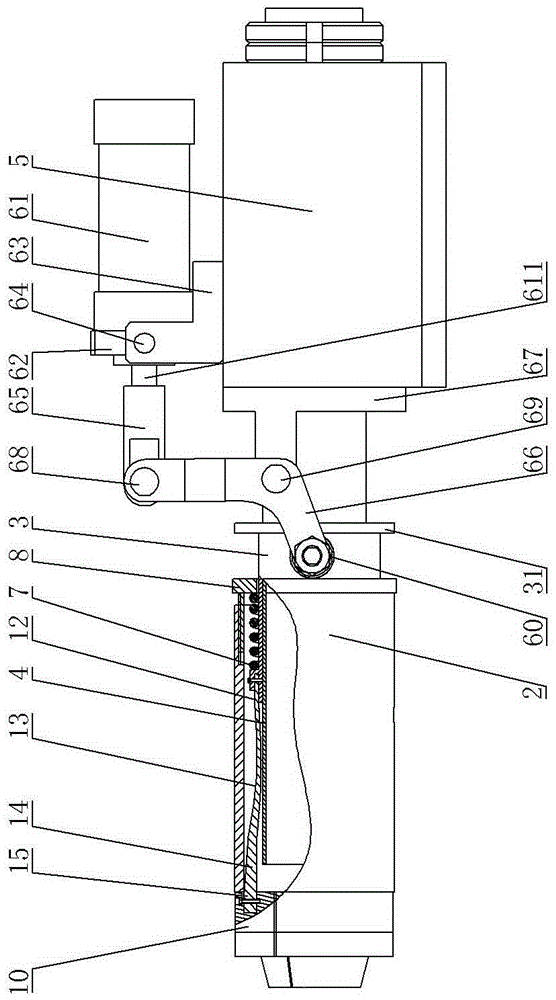

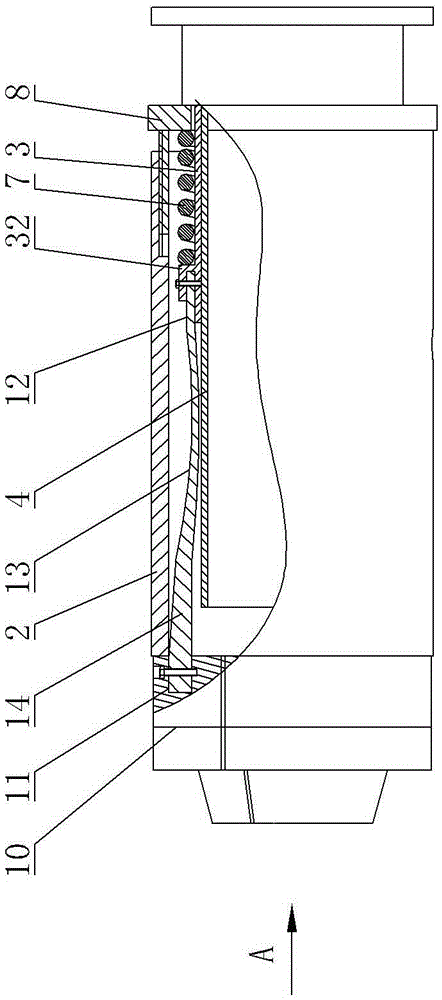

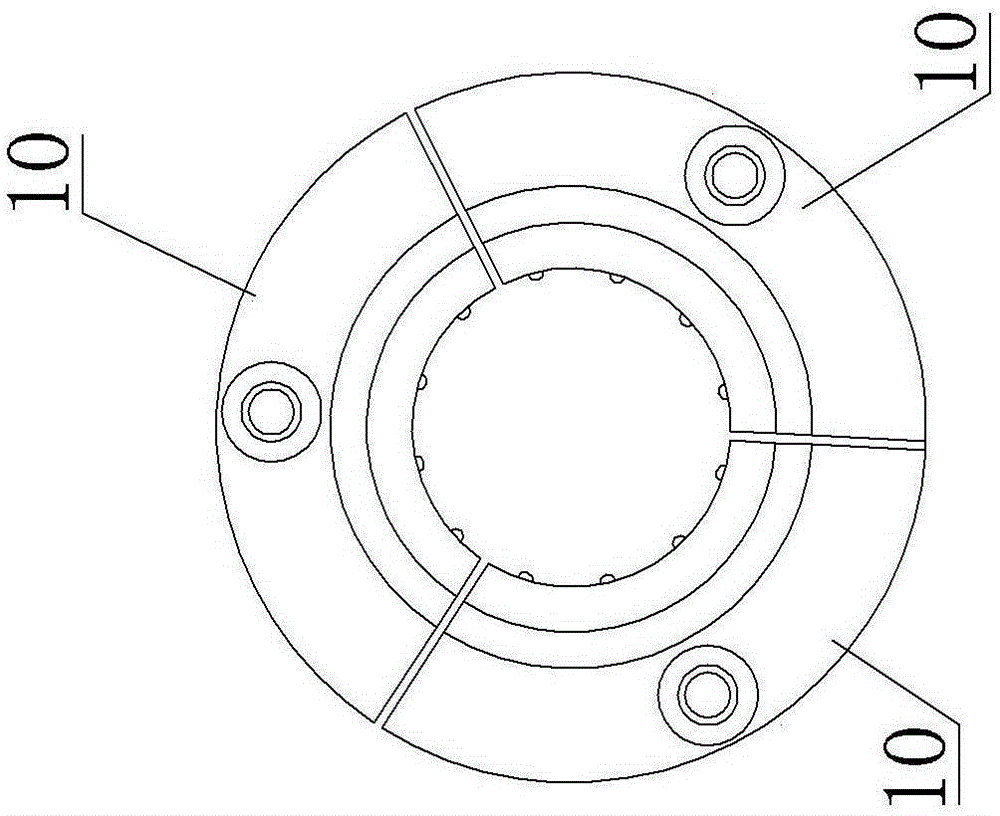

[0013] Such as Figure 1 to Figure 4 As shown, it includes jaws for clamping copper pipes, sleeve 2, adjustment sleeve 8, sleeve seat 3, base sleeve 4, base 5 and driving device. The base sleeve 4 is installed on the base 5, the sleeve seat 3, the adjusting sleeve 8, and the sleeve 2 are sequentially set on the base sleeve 4, the sleeve base 3 is fixedly connected with the base sleeve 4, and the adjusting sleeve 8 is threadedly connected with the sleeve 2, The sleeve 2 moves axially along the base sleeve 4 under the action of the driving device. The jaws include a collet 10, a mounting part 15, a connecting part 14, an arc-shaped elastic connecting arm 13 and a snap ring 12. One side of the snap ring 12 is installed in the annular slot 32 on the outside of the sleeve seat 3 and passed through the bolt. It is fixedly connected with the side wall of the ring-shaped groove 32, and the other side of the ring is distributed with three elastic connecting arms 13 along the ring-shap...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap