Machining method of mold insert for high mirror surface mold of convex glass

A technology of mold core insertion and processing methods, which is applied in the field of mold processing, can solve the problems of scratch protection damage, processing discharge corrosion, etc., and achieve the effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

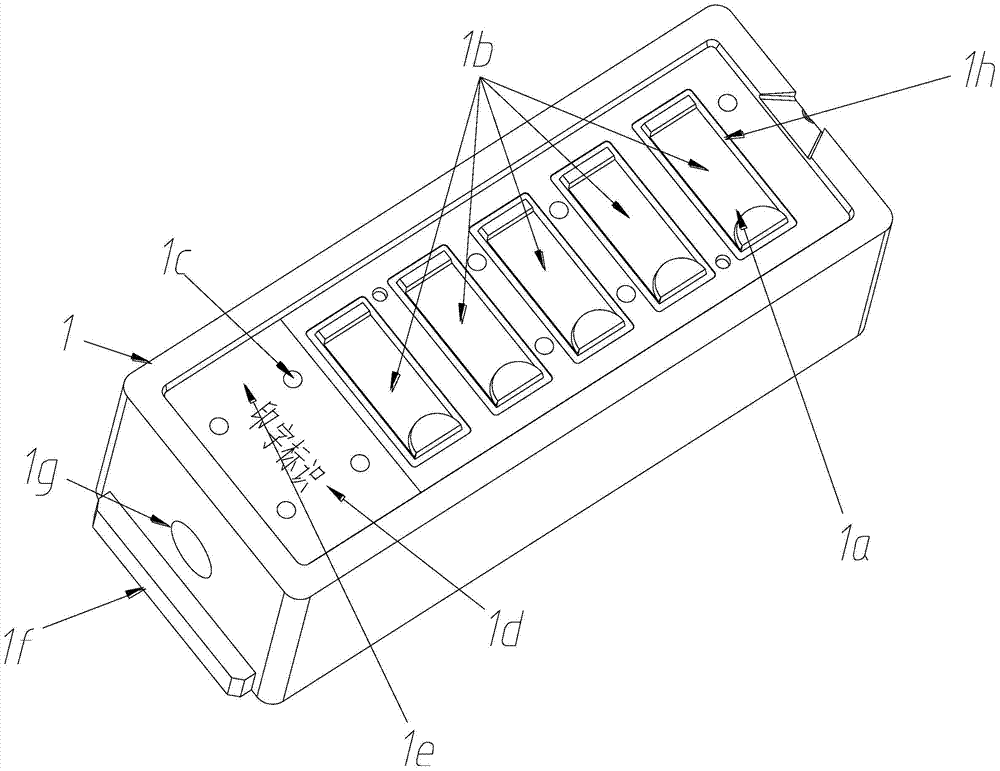

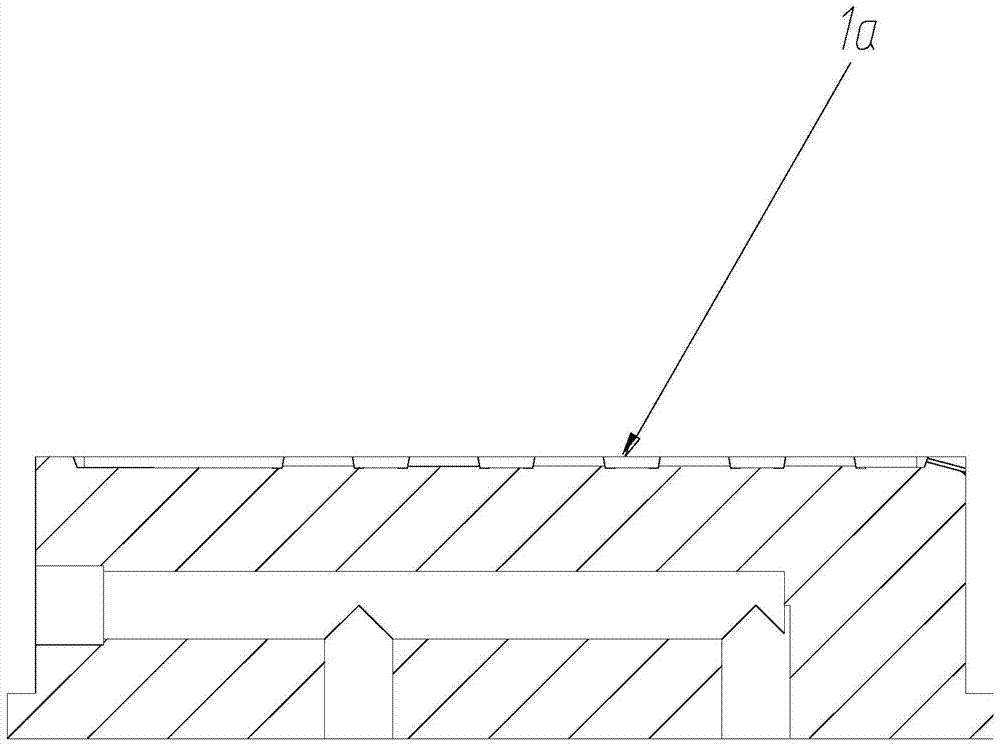

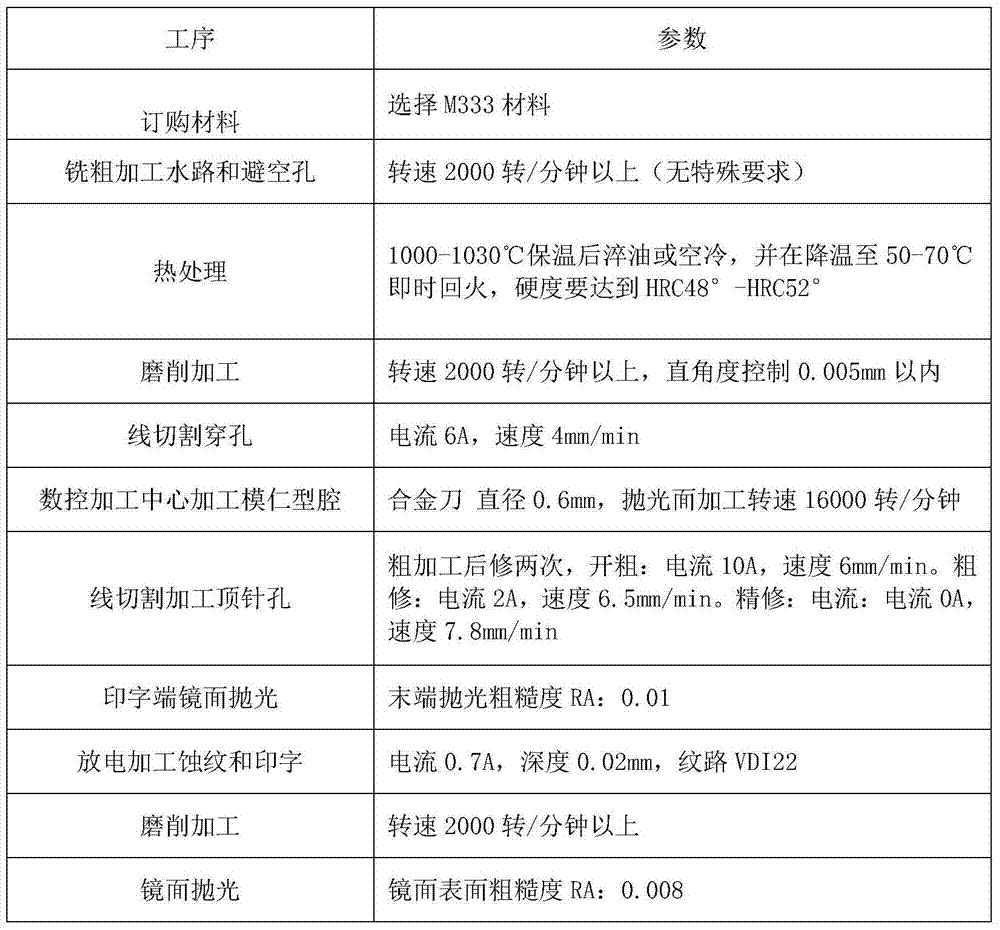

[0034] refer to image 3 As shown, the method for processing the core of the convex glass high-mirror mold of the present embodiment includes the following steps carried out in sequence:

[0035] 1) According to the shape of the mold core, order the material with sufficient machining allowance. The selection of the material fully takes into account the strict requirements on the appearance of the final injection molding product. In this example, the M333 mold steel material is selected as the raw material for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com