Reworking apparatus, reworking method and reworking solution for electronic equipment

An electronic device and heavy industry technology, applied in the field of heavy industry solutions, can solve the problems of manpower, time and resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

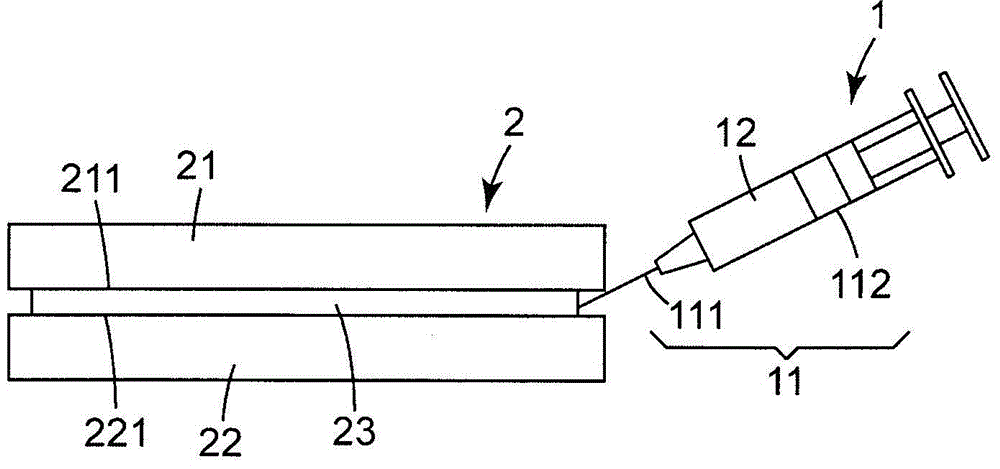

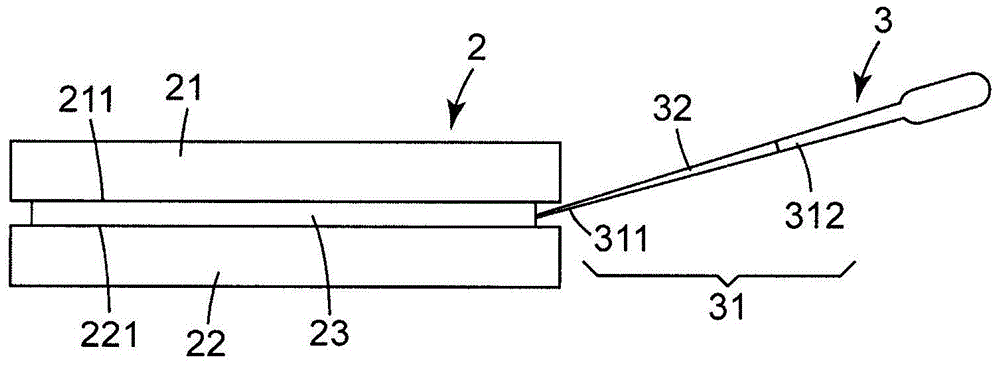

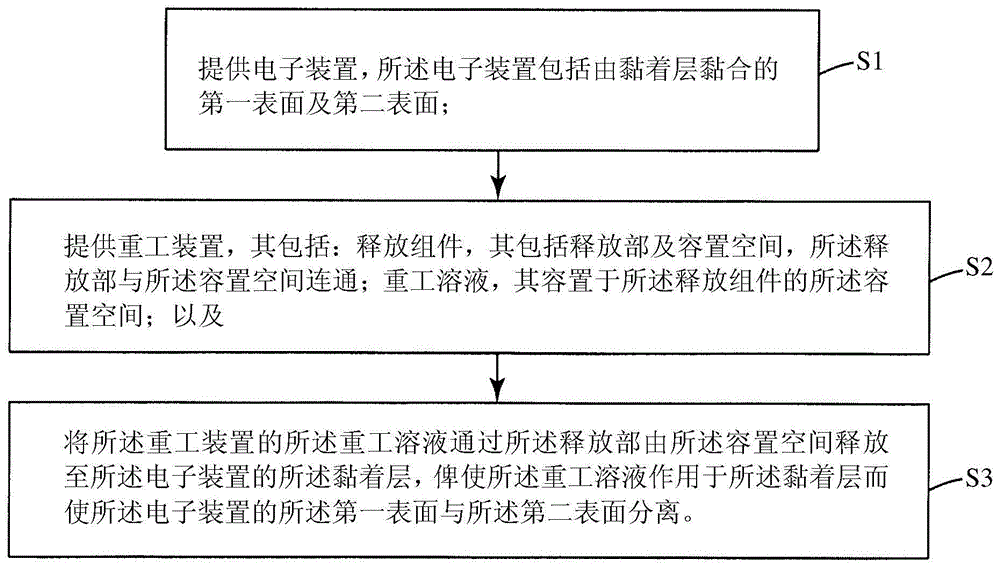

Method used

Image

Examples

experiment example 12

[0033] Experimental Example 12 is D-limonene: ethanol: anionic surfactant sodium dodecyl sulfate ((Sodiumdodecylsulfate, SDS, model: 62862, purchased from Sigma-Aldrich) is mixed in a ratio of 1:1:0.1 (wt%) and The resulting rework solution, and 1.5ml of the rework solution of Experimental Example 12 was injected into a 3M with a width of 3mm TM VHB TM Adhesive tape (4914-025) for 72 hours on commercially available ink-printed glass (TMBK945) and polycarbonate substrate For the joint, the pressing condition is 15 PSI, 15 seconds, and the static tensile strength test value (ASTMD3654) is tested with a load of 4Kg at a room temperature of 23°C. The results show that Experimental Example 12 can separate the ink-printed glass from the polycarbonate substrate within 21 minutes, but the combination of the ink-printed glass and the polycarbonate substrate without any treatment is still tight after more than 10,000 minutes glue. It can be seen that the reworking solution of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com