Energy accumulation type high-speed and high-acceleration tester

A testing machine, high-acceleration technology, applied in measurement devices, instruments, etc., can solve problems such as high cost and difficulty in implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with example (accompanying drawing).

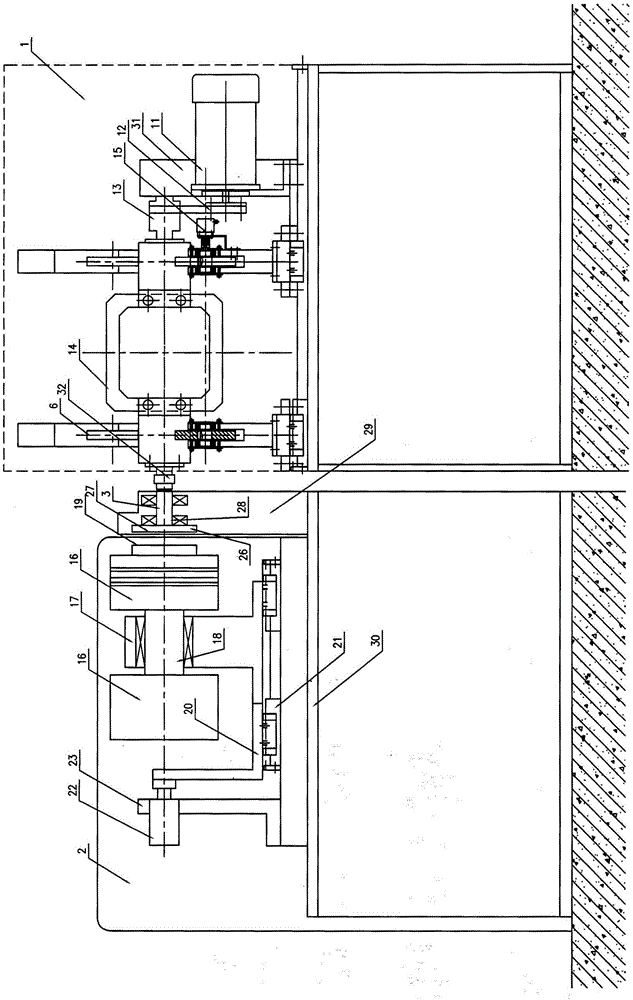

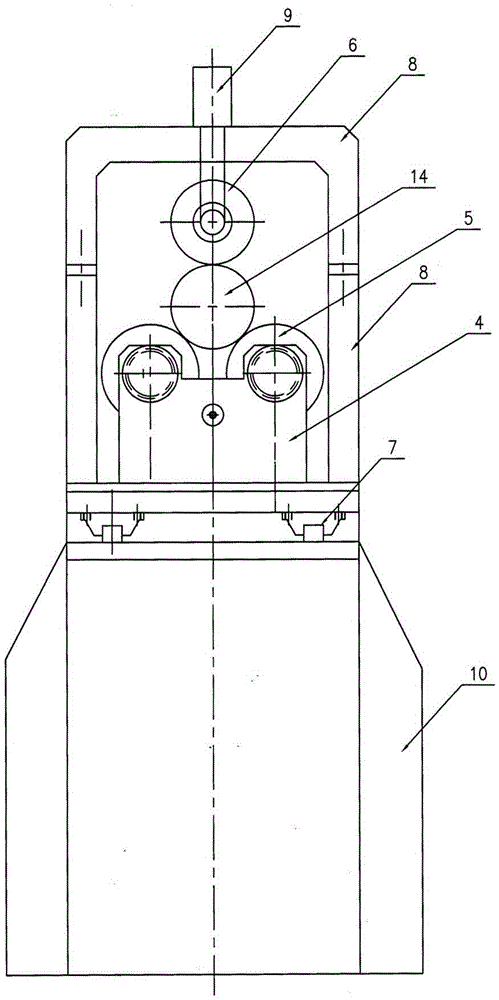

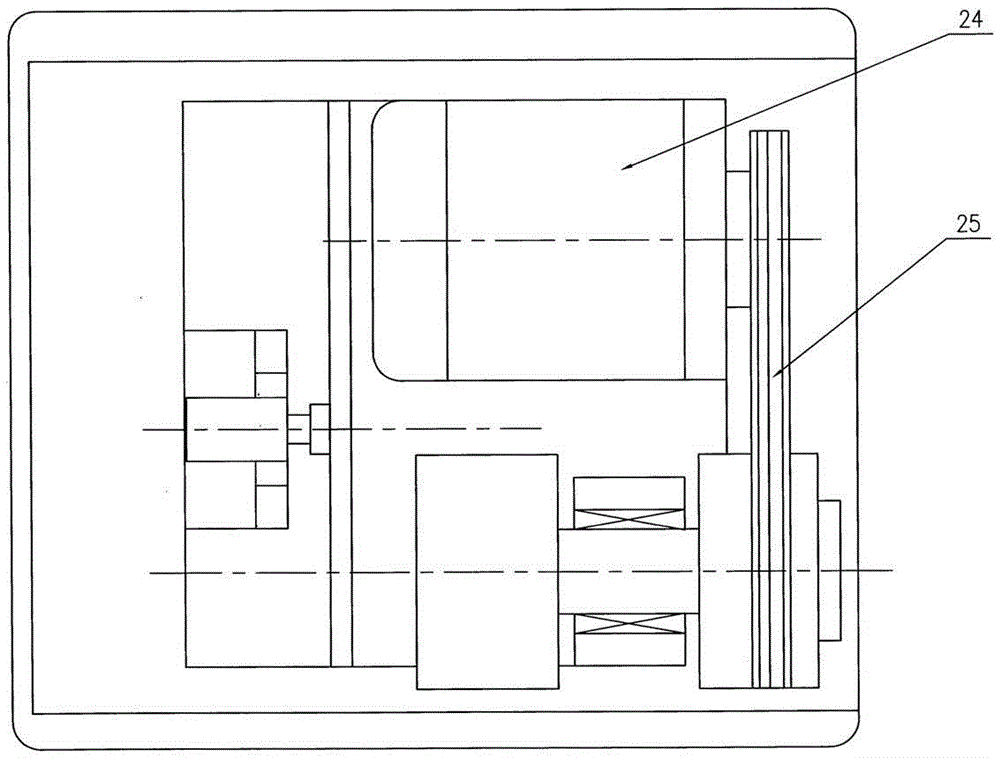

[0021] Such as figure 1 , 2 , 3, the energy storage type high-speed high-acceleration testing machine of the present invention includes a high-speed host part, an energy storage drive and a clutch part, an axial vibration isolation and a speed-up part; the high-speed host part includes a The front and rear protective brackets 8 and the front and rear roller bearings 4 are respectively installed on the front and rear roller bearings 4 through bearings. The front and rear pressure rollers 6 hoisted under the upper beams of the front and rear protective brackets 8, and the connecting tooling 14 supported and driven by the front and rear roller groups 5 and the front and rear pressure rollers 6 (forming a stable structure of triangular support, and drive the connection tooling and the workpiece to be tested to rotate at high speed); the front and rear roller bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com