A fulcrum press for fuel rod cladding tubes

A technology of pressing machine and cladding tube is applied in the field of reactor engineering to achieve the effects of simple operation, high quality of fulcrum pressing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in combination with the accompanying drawings and specific embodiments.

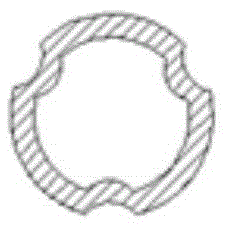

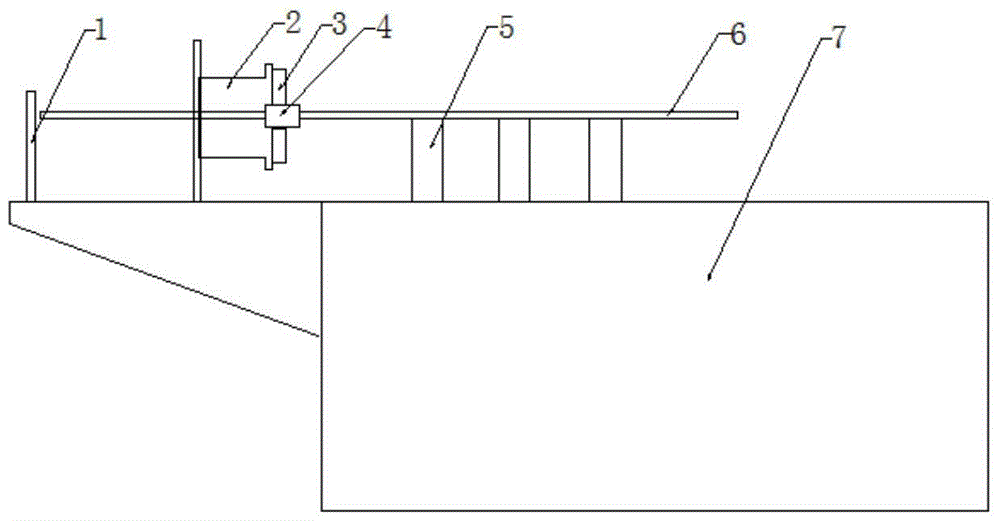

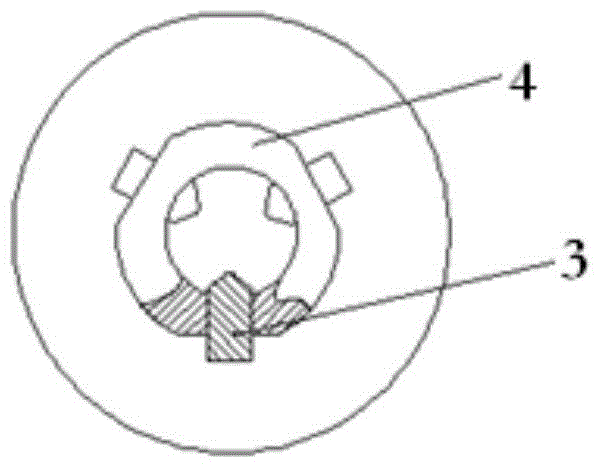

[0025] A fulcrum press for fuel rod cladding tubes, such as figure 2 and image 3 shown. The pressing machine mainly includes a bracket 7 and a self-centering three-jaw chuck 2 located on the bracket 7, a chuck core 4, an indenter fixing device, a conical indenter 3, a limit plate 1 and a support for cladding. The support plate 5 of the tube, the number of support plates 5 is 3; the three-jaw chuck 2 is fixedly connected with the chuck core 4, and the indenter 3 is fixed on the claw of the self-centering three-jaw chuck 2 through the indenter fixing device Above, the number of the indenter 3 and the indenter fixing device are three; the limit plate 1 is provided with an oblong hole, and the distance between the indenter and the lower end plug of the cladding tube can be adjusted according to the fulcrum pressing requirements.

[0026] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com