Shale gas horizontal well staged fracturing method and shale gas horizontal well completion method

A technology for staged fracturing and horizontal wells, which is applied in staged fracturing of shale gas horizontal wells and completion of shale gas horizontal wells. The probability of the drill plug being blocked, the low cost and the effect of convenient construction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

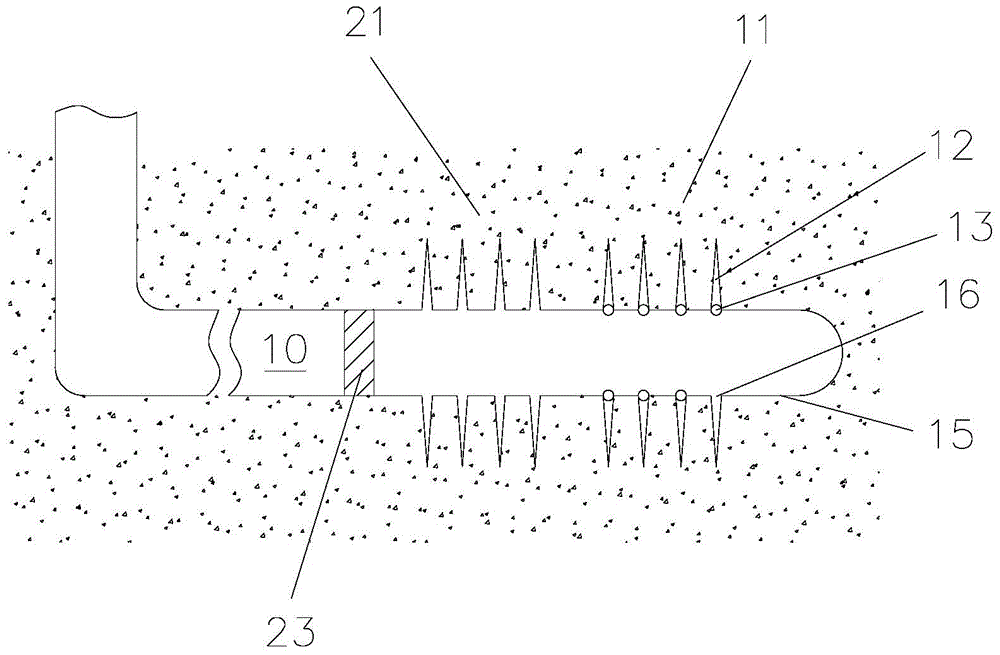

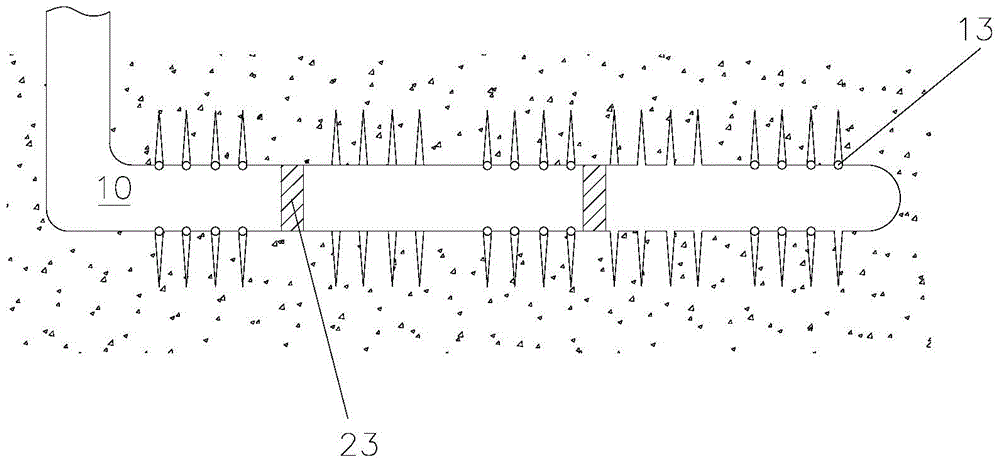

[0022] The method according to the invention is usually performed after cementing. figure 1 It schematically shows the process of fracturing and ball setting of the lower production layer in the well according to the present invention.

[0023] Firstly, a perforating gun (not shown) is lowered into the wellbore 10 into the expected production zone 11 (or the first layer 11 ) to perforate, and the perforation holes 16 are formed on the casing 15 . Typically, the first layer 11 is the lowest producing layer. Perforating guns and perforating operations are well known to those skilled in the art and will not be repeated here. After the perforation is completed, the well is filled with high-pressure fluid for fracturing, and the production layer fractures 12 are formed in the first layer 11 . The number of production layer fractures 12 is usually multiple. Formation exudates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com