Improvement method of eccentric sleeve of high-speed precision roll grinding head and its eccentric sleeve

An eccentric sleeve and precise technology, applied in the field of eccentric sleeve, can solve the problems of high processing cost, many oil guide grooves, and inability to adjust the eccentric sleeve dynamic and static pressure bearing, so as to reduce the loss and improve the oil inlet pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

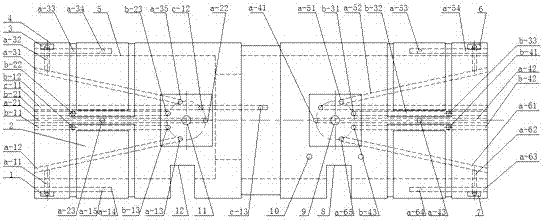

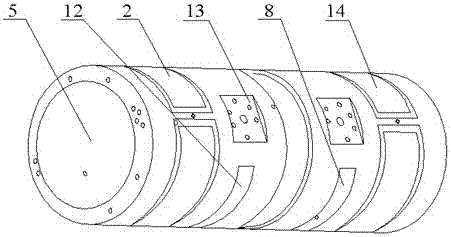

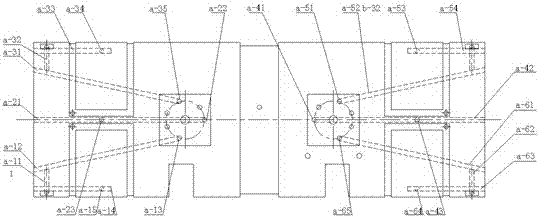

[0023] Such as figure 1 with figure 2 As shown, the eccentric sleeve of the present invention has two main functions:

[0024] 1. Open the oil guide groove inside the eccentric sleeve 4, and introduce the oil flowing into the eccentric sleeve 4 from the restrictor into the hydrostatic bearing and the hydrostatic bearing chamber to provide lubricating oil for the bearing; 2. Rotate the eccentric sleeve 4 to change the dynamic and static pressure bearing The center line is used to change the center position of the spindle of the roll grinder to achieve medium-high (concave) grinding. How the eccentric sleeve 4 conducts oil and how to realize the middle and high two aspects are mainly described below.

[0025] The details are as follows:

[0026] Eccentric sleeve 4 guide oil principle:

[0027] In the grinding process of the high-speed precision roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com