Mechanical electric heating frying cylinder for producing chicken granules

A chicken diced, mechanical technology, applied in the field of chicken diced production equipment, can solve the problems of time-consuming and laborious, difficult temperature control, manual classification, etc., and achieve the effects of reducing cost, ensuring uniformity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

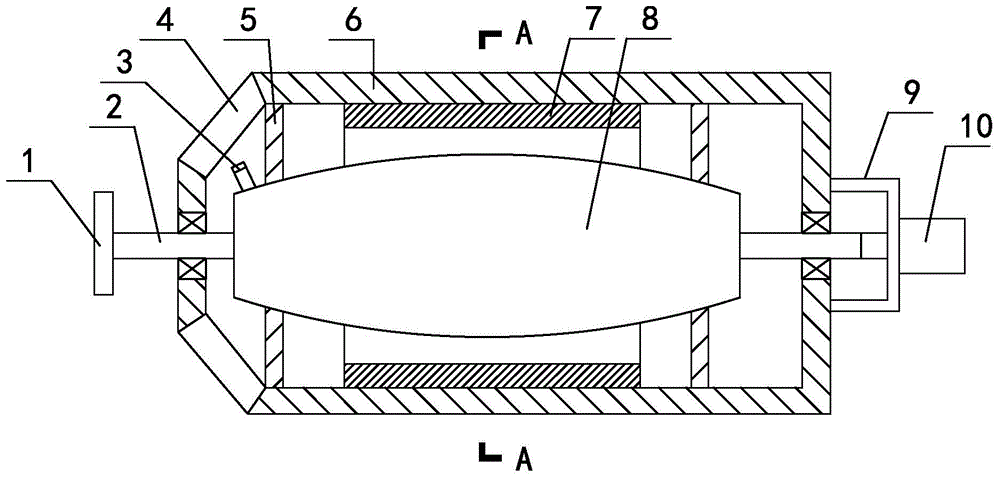

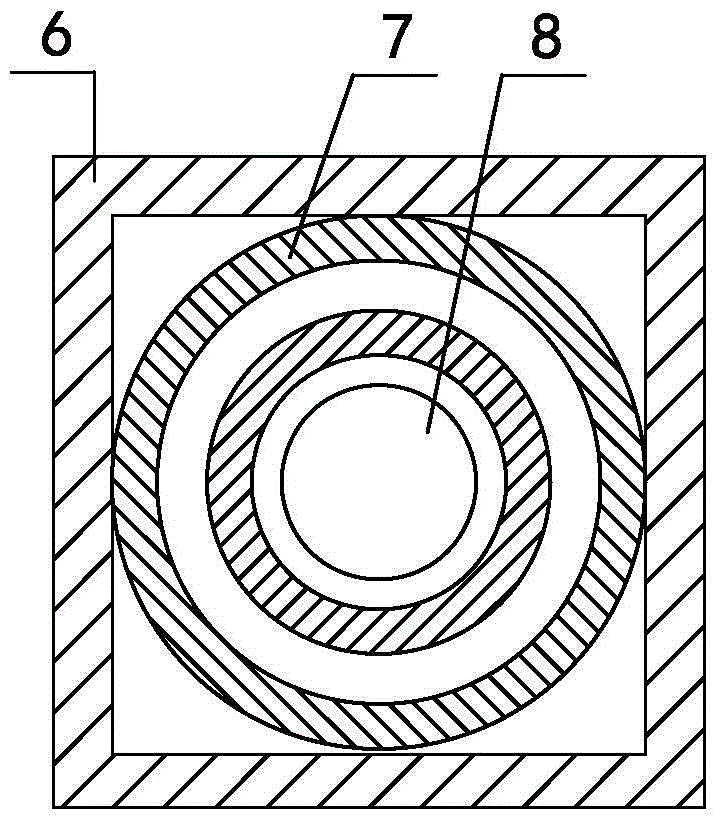

[0015] like figure 1 , figure 2 As shown, the mechanical electric heating frying drum for making chicken nuggets includes a sealed box 6 and a drum 8 for frying chicken nuggets. There is a feeding port 3, corresponding to the feeding port 3, a feeding door 4 and a discharging door are respectively set at the upper left corner and the lower left corner of the box body 6, and the left and right sides of the cylinder body 8 are respectively fixed with a rotating shaft 2 horizontally, and the rotating shaft 2 passes through The bearing is installed on the box 6, the left end of the left rotating shaft 2 is installed with a handle plate 1 for the rotation of the rotating shaft 2, the right end of the right rotating shaft 2 is installed with a motor 10 for the mechanical rotation of the rotating shaft 2, and the motor 10 is installed by The frame 9 is installed on the right side wall of the box body 6, and corresponding to the heating surface of the cylinder body 8, a ring-shaped ...

Embodiment 2

[0019] On the basis of Example 1, the distance between the electric heating wire 7 and the cylinder body 8 is changed to 55 mm. Others are the same as the first embodiment.

Embodiment 3

[0021] On the basis of Example 1, the distance between the electric heating wire 7 and the cylinder 8 is changed to 60 mm. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com