Imitation stainless steel brushed coated aluminum plate and manufacturing method thereof

A technology of imitating stainless steel and manufacturing method, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of high cost, low fastness, and environmental protection, and achieve good coating thickness uniformity, good Shear leveling performance, colorful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

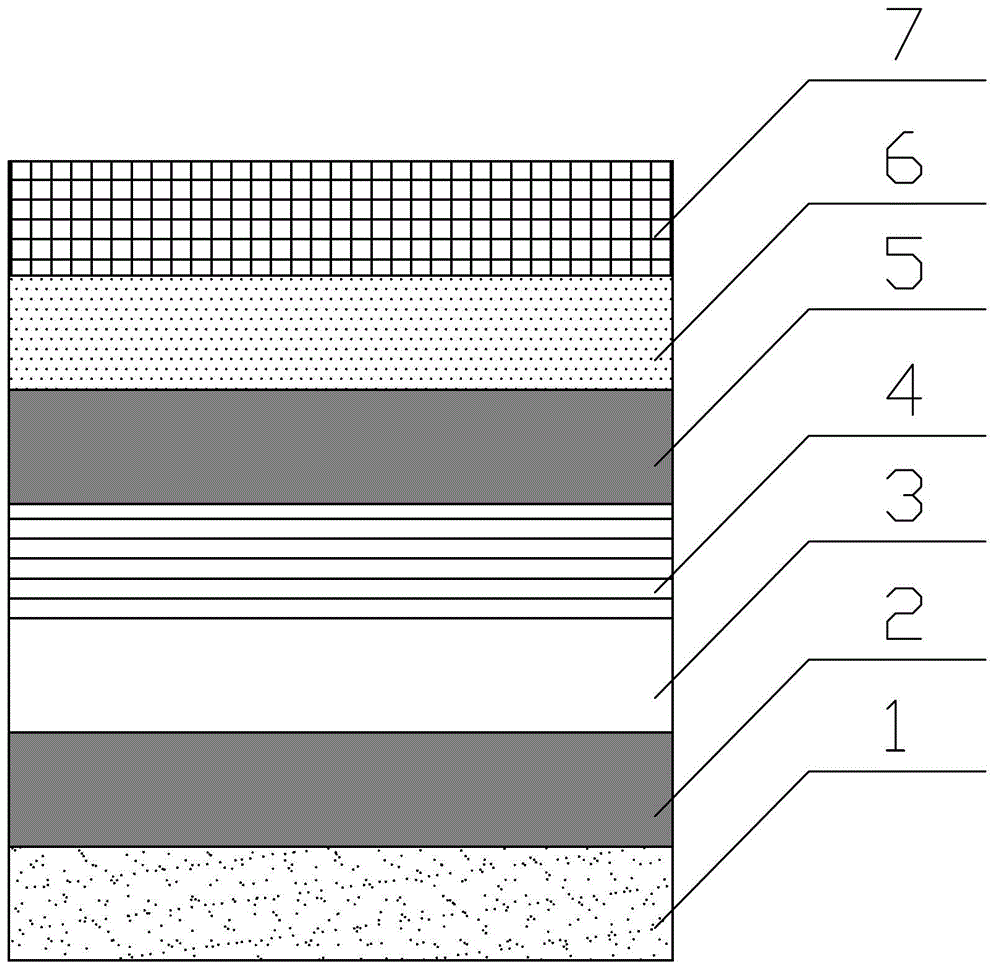

[0032] The present invention imitates the stainless steel drawing coated aluminum plate, with reference to figure 1 , including an alloy aluminum substrate 3, on the top (front side) of the alloy aluminum substrate 3 are a wire drawing layer 4, a first passivation layer 5 and a top coat 6; Passivation layer 2 and back paint layer 1.

[0033] Wherein, the alloy aluminum substrate 3 is a 3004H24 aluminum plate, and the top coat 6 further includes a protective layer 7, and the protective layer 7 is a polyethylene protective film.

[0034] The method of manufacturing the stainless steel wire drawing coated aluminum plate of this embodiment is as follows: the alloy aluminum base material is subjected to wire drawing, pre-treatment degreasing, chromization, and then high-temperature baking after coating the top coat to form the imitation stainless steel wire drawing coating of the present invention. Layer aluminum plate, among which, the top coat is polyethylene terephthalate resin...

Embodiment 2

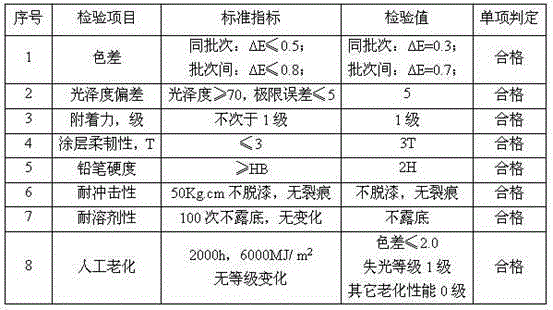

[0040] The principle and setting of this embodiment are the same as those of Embodiment 1, the difference is that the alloy aluminum substrate 3 is 5052H24 in the aluminum 5 series, and the topcoat layer 6 is polyethylene terephthalate provided by Beike Industrial Coatings Shanghai Co., Ltd. Alcohol ester resin colored transparent varnish (model BD2700075), which is obtained by modifying the gloss, impact resistance, weather resistance, flexibility and solvent resistance according to the standard; the protective layer 7 is a polyethylene protective film, and the wire drawing is made of Short brushed effect, when baking at high temperature, the temperature is 225~235°C, and the baking time is 70 seconds.

[0041] According to the test standard and method of Example 1, the properties of the imitation stainless steel wire-drawn coated aluminum plate prepared in this example were tested, and the results are shown in Table 3.

[0042] Table 3 Performance Parameters of Example 2 Imi...

Embodiment 3

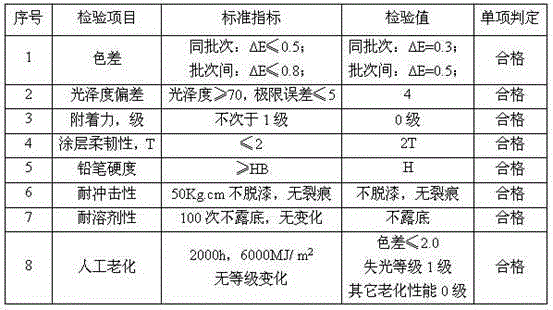

[0045] The principle and setting of this embodiment are the same as those of Embodiment 1, the difference is that the alloy aluminum substrate 3 is 7075 in the aluminum 7 series, and the top coat 6 is polyethylene terephthalate resin provided by PPG Industries Co., Ltd. The color transparent paint (model APBC3250) is obtained by modifying the gloss, impact resistance, weather resistance, flexibility and solvent resistance according to the standard. The protective layer 7 is the anti-fingerprint layer, and the drawing adopts random drawing effect. The temperature during high-temperature baking is 200-230° C., and the baking time is 90 seconds.

[0046]According to the test standard and method of Example 1, the properties of the imitation stainless steel wire-drawn coated aluminum plate prepared in this example were tested, and the results are shown in Table 4.

[0047] Table 4 The performance parameters of Example 3 imitation stainless steel wire drawing coated aluminum plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com