Disassembling device and method for power turbine disc of lightweight gas turbine

A technology for power turbines and gas turbines, which is applied in the field of light gas turbine power turbine disk decomposition devices, and can solve problems such as adhesion, difficulty in decomposition, and corrosion of power turbine disks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

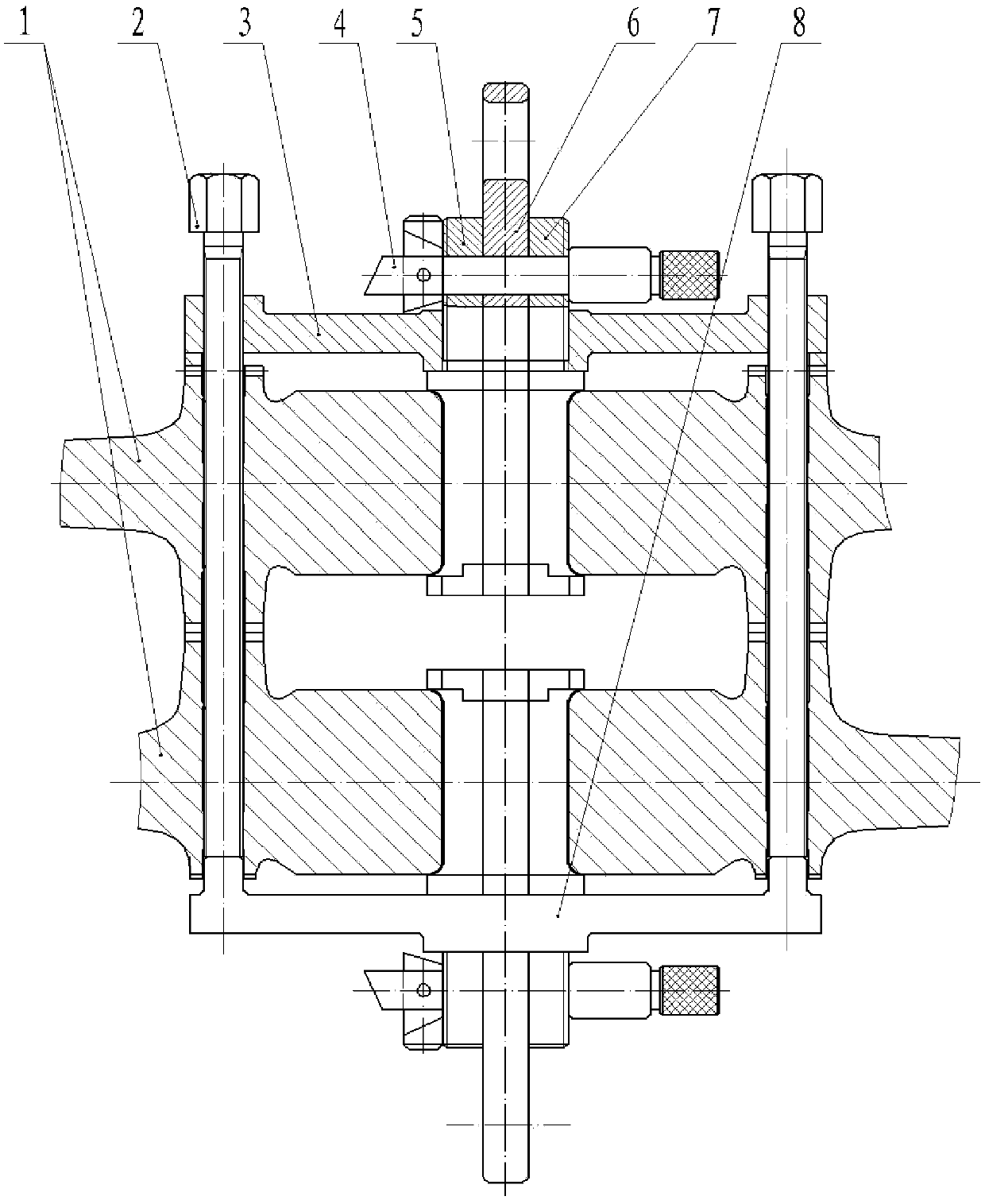

[0016] In the light-weight gas turbine power turbine disc decomposition device, the left and right ends of the turbine disc 1 are symmetrically provided with connecting holes, and the middle part of the turbine disc 1 is provided with a vertical symmetrical shaft hole, and is characterized in that: the light-weight gas turbine power turbine disc decomposition device is constituted as follows : Top screw 2, upper pressing plate 3, positioning pin assembly 4, left block body 5, core block body 6, right block body 7 and lower pressing plate 8; upper pressing plate 3 is provided with a through hole structure corresponding to the connecting hole, upper pressing plate 3 Screwed to the upper end of the turbine disc 1 through the screw rod 2, the connecting hole and the through hole structure, the lower pressing plate 8 is provided with a boss structure at the corresponding position of the connecting hole, and the lower pressing plate 8 is connected to the turbine disc through the boss s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap