Lifting seat sleeve structure of automobile co-driver seat

A technology for passenger seats and seat covers, applied in seat covers, vehicle seats, vehicle parts, etc., can solve the problems of occupying space in the car, inconvenient storage and use, and inconvenience in searching, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

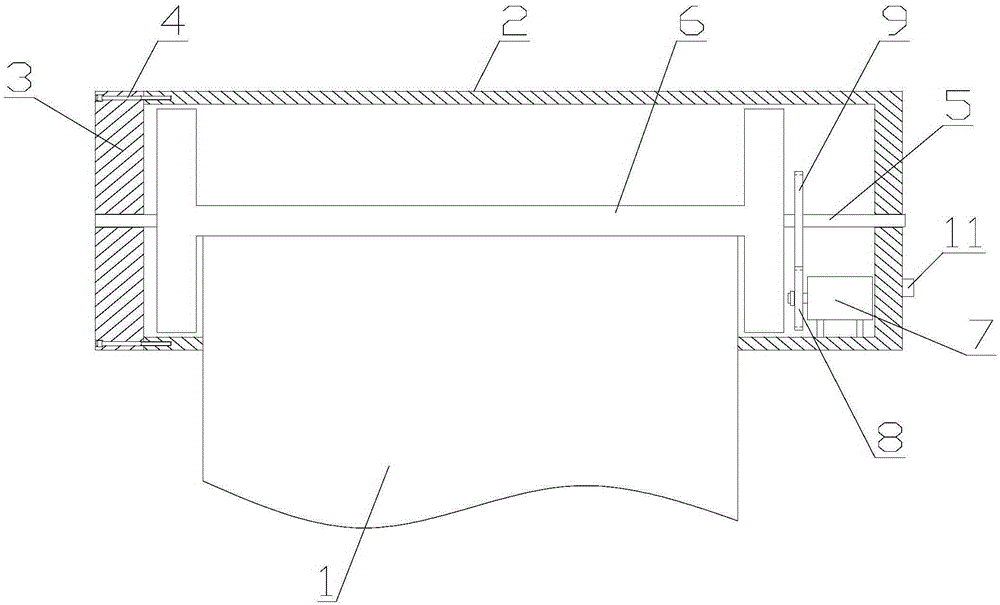

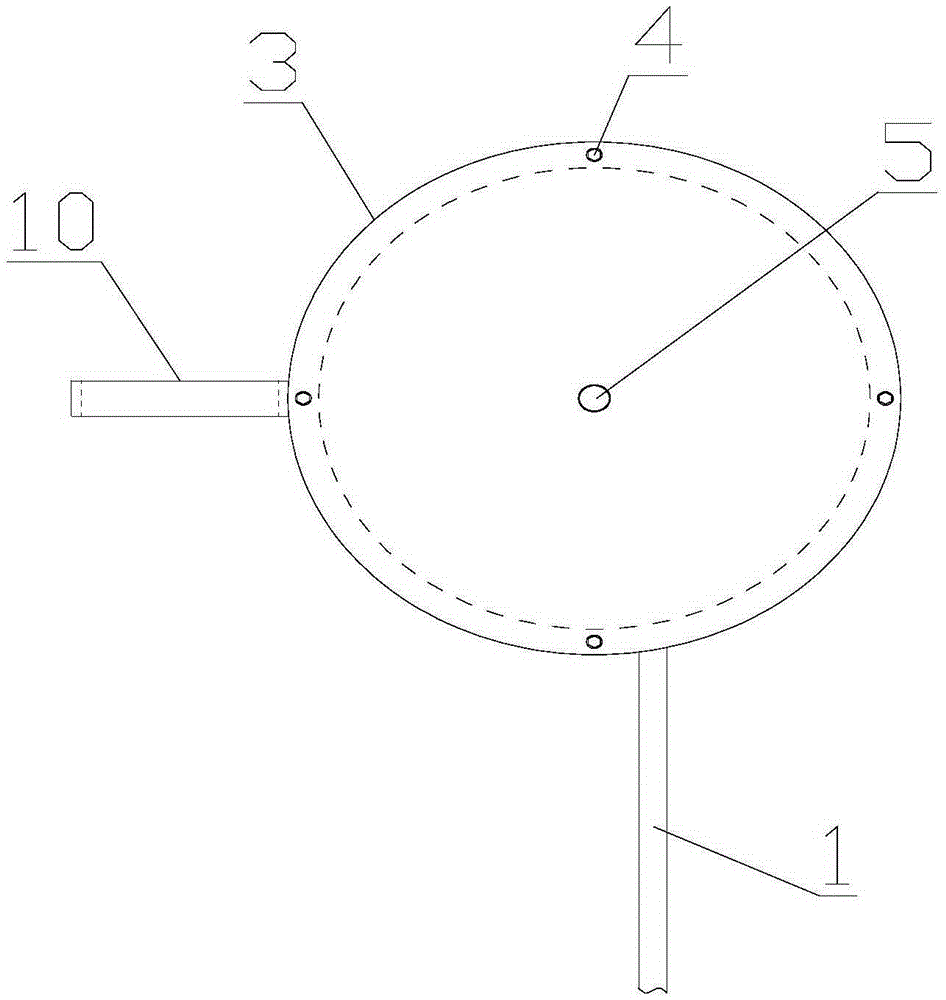

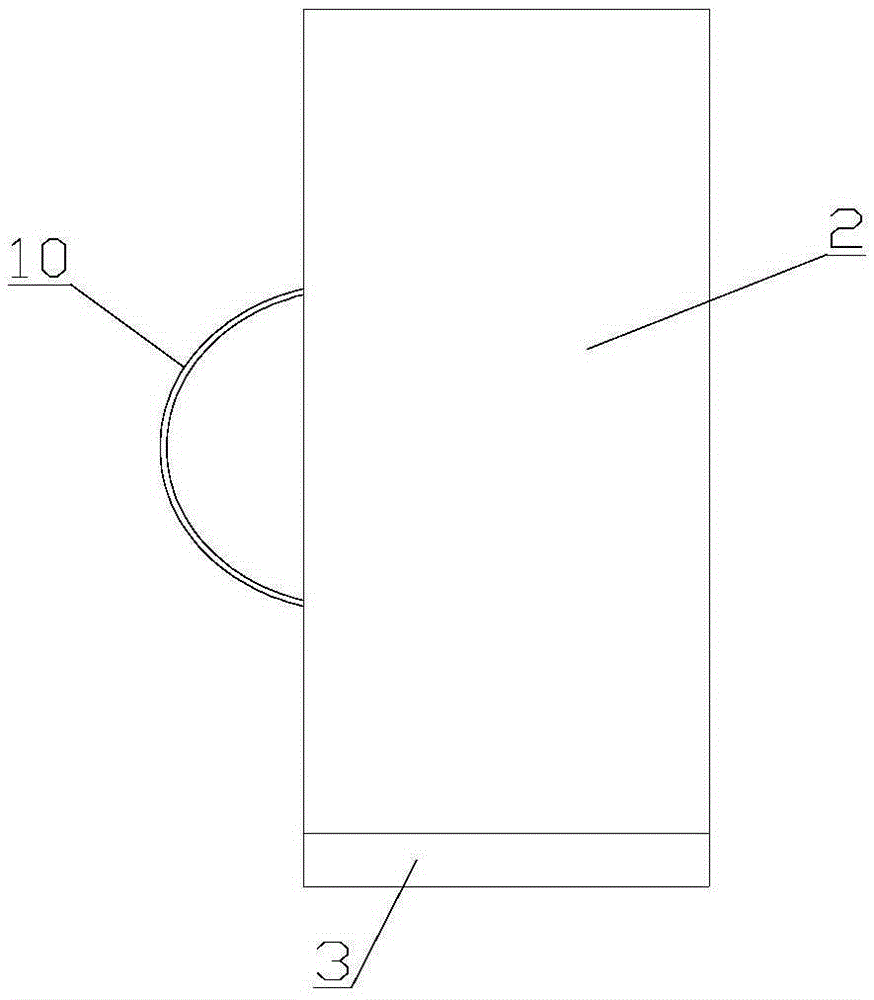

[0014] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 left view of image 3 for figure 2 As shown in the figure: the liftable seat cover structure of the passenger seat of the automobile in this embodiment includes a seat cover 1 and a reel 2 for winding the seat cover 1, one end of the reel 2 is closed, and the other end Open, the open end of the reel 2 is connected with the end cover 3 through the locking bolt 4, so that the reel 2 and the end cover 3 form a detachable connection, which is convenient for installation, disassembly and replacement. The reel 2 is provided with a rotating shaft 5, Roller 6 and driving motor 7, the two ends of described rotating shaft 5 are respectively rotatably supported on the closed end of reel 2 and end cover 3, and described roller 6 is fixedly connected on rotating shaft 5 in the circumferential direction, and described driving The motor 7 is located on the side of the reel 2 close to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com