Solar steam generation device

A technology of solar steam and generating device, applied in the field of solar energy application, can solve the problems affecting service life, production service, complex structure, etc., and achieve the effect of prolonging service life, improving reliability and good heat collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

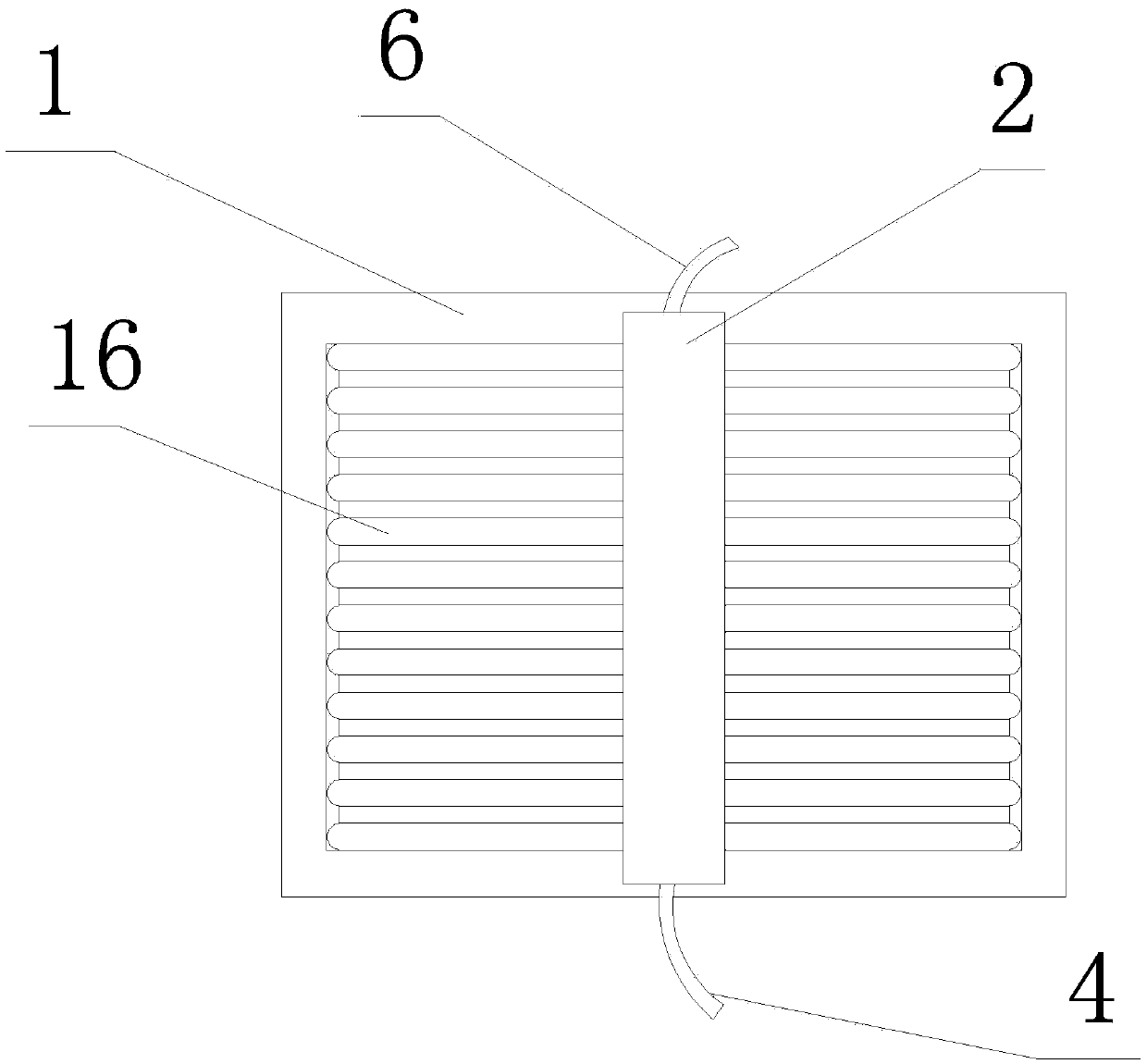

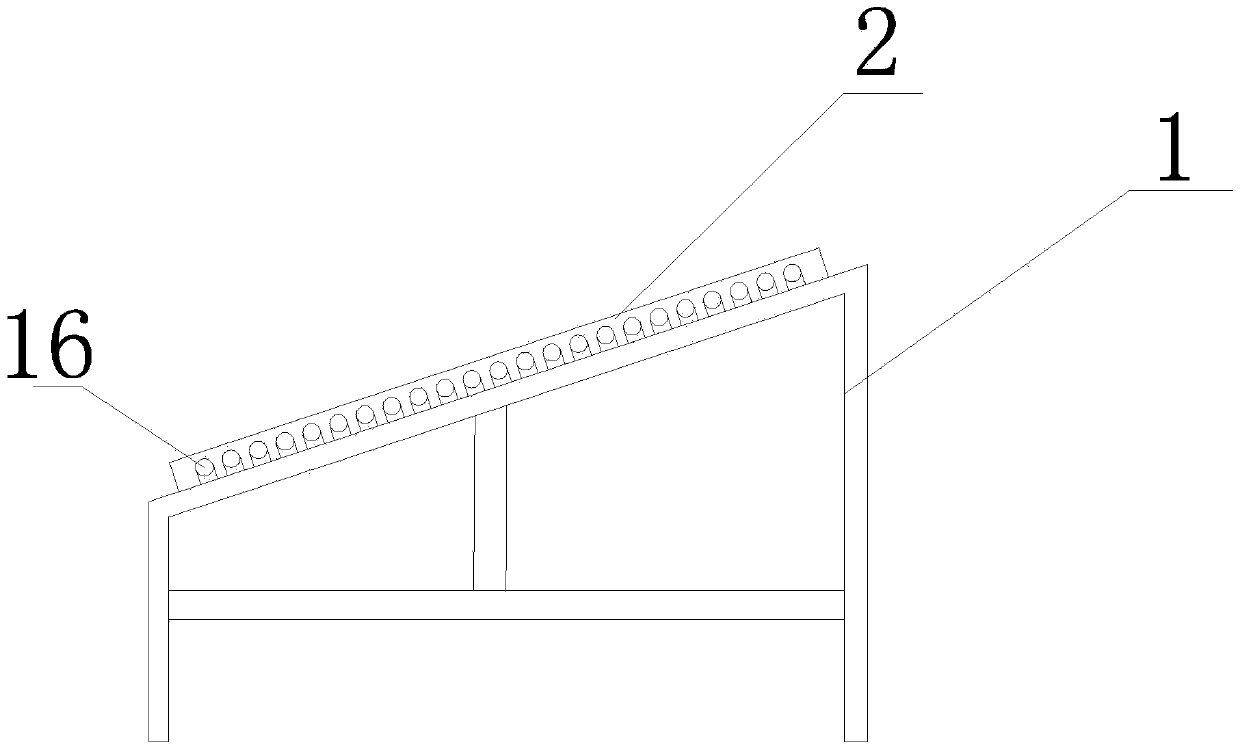

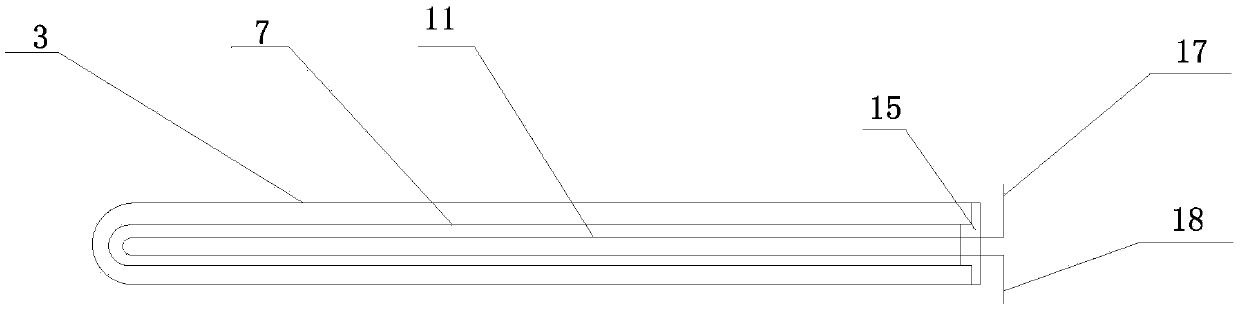

[0029]The second embodiment is one heat exchange tube 11, one heat exchange tube 11, and the heat exchange tubes 11 alternately enter the inner tube 7 of the left and right heat collecting tubes 16 to form a serpentine distribution. This embodiment has only one steam outlet 18. However, in the process of steam generation, the transmission path is long, the water is fully evaporated, the quality of the output steam is high, and the temperature and pressure of the steam are also high. This kind of solar steam generating device can quickly reach 120 Celsius to 200 degrees Celsius, it can also be connected in series through the headers 2, 50 heat collector tubes 16 as a group, a group of modules can generate 2KW of heat, the heat collection effect is good, the performance temperature is high, and it is durable. Multiple solar steam generating devices can be connected in series or in parallel to generate a large amount of saturated steam, series can generate higher temperature steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com