A laser based on the combination of self-Raman and opo

A laser and combined technology, applied in the field of lasers, can solve the problems of difficult adjustment, high cost, complex laser cavity structure, etc., and achieve the effect of convenient adjustment and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

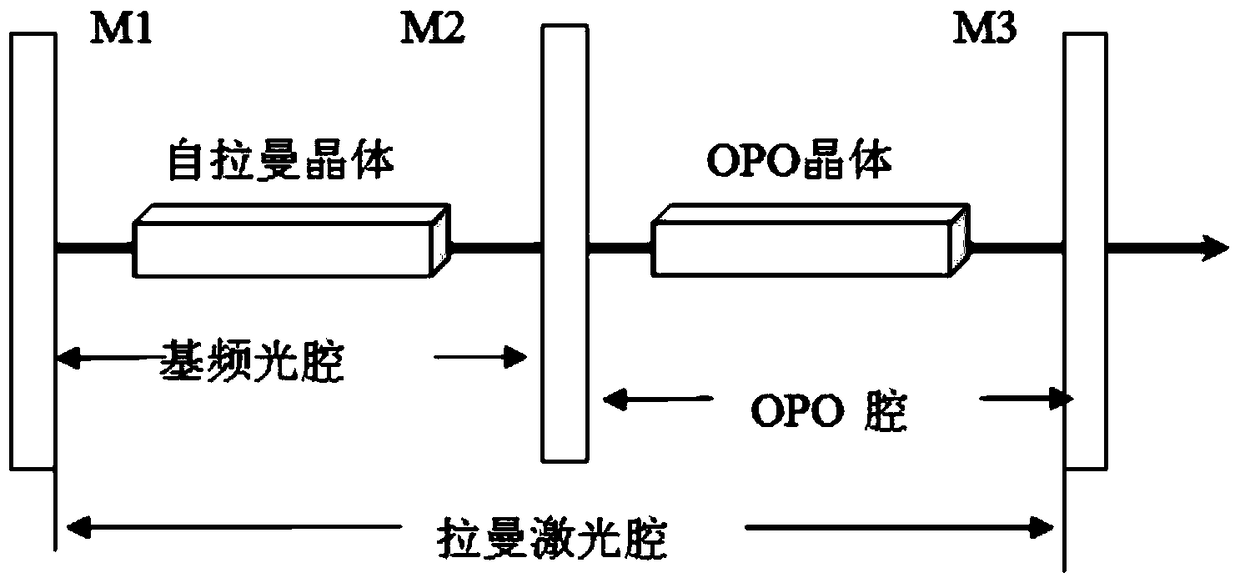

[0049] like figure 1 As shown, cavity mirror M1 and cavity mirror M2 form a fundamental frequency optical cavity, M2 and cavity mirror M3 form an OPO cavity, M1 and M3 form a Raman optical cavity,

[0050] The fundamental frequency optical cavity is isolated from the OPO optical cavity, and the Raman optical cavity covers the fundamental frequency optical cavity and the OPO optical cavity.

[0051] Coating requirements are as follows: M1 is highly reflective to fundamental frequency light and Raman light; one side of M2 is to fundamental frequency light, and the other is highly reflective to parametric light (signal light and (or) idler light). High transmittance of Raman light; M3 is highly reflective to Raman light and partially transmits to parametric light (signal light and (or) idler light);

[0052] Self-Raman crystal coating enhances the transmission of fundamental frequency light and Raman light;

[0053] OPO crystal coating is anti-reflective to Raman light and para...

Embodiment 2

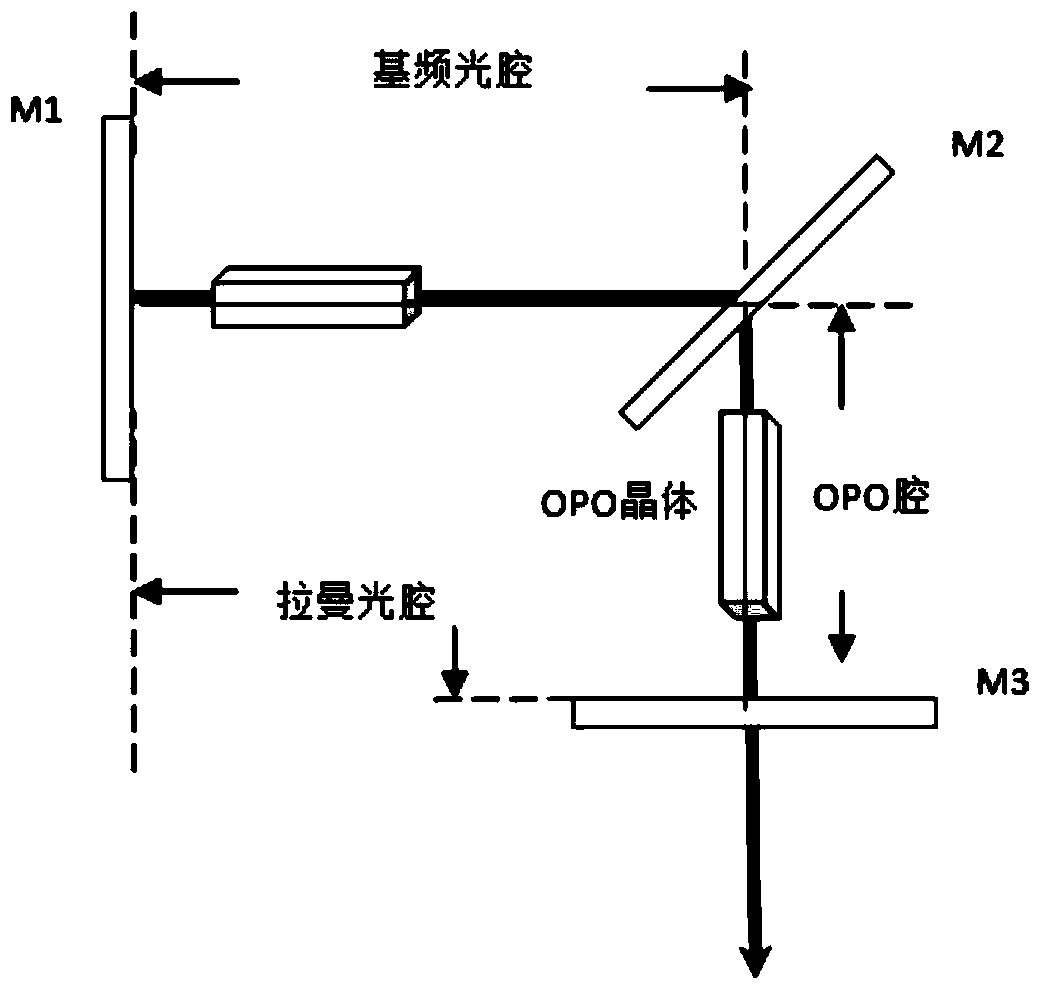

[0057] like figure 2 As shown, the line connecting the first cavity mirror and the second cavity mirror forms a right angle or other angles with the line connecting the second cavity mirror and the third cavity mirror, and other settings are consistent with the first embodiment.

Embodiment 3

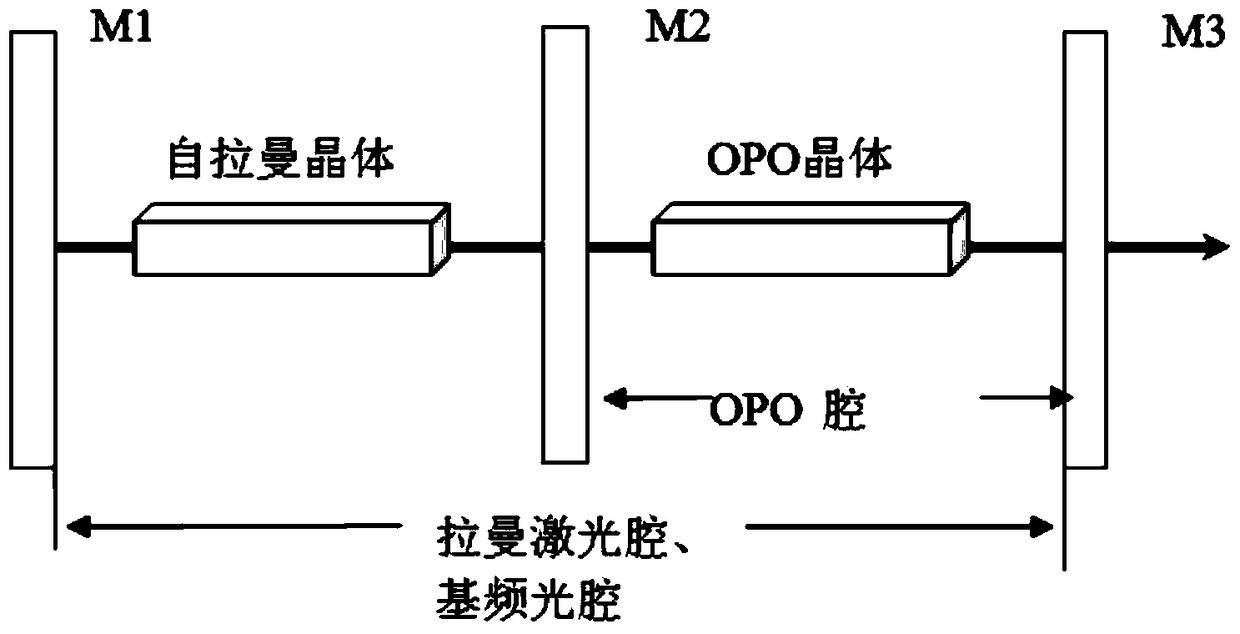

[0059] like image 3 As shown, M1 and M3 form a fundamental frequency optical cavity, which is also a Raman optical cavity, and M2 and M3 form an OPO cavity. The fundamental frequency light and the Raman optical cavity coincide.

[0060] Coating requirements: M1 is highly reflective to fundamental frequency light and Raman light; M2 is highly reflective to parametric light (signal light and (or) idler light) on one side, and highly transparent to Raman light and fundamental frequency light on both sides; M3 is highly reflective to parametric light (signal light and (or) idler light) Fundamental frequency light and Raman light are highly reflective, and partly transmitted to parametric light (signal light and (or) idler light);

[0061] Self-Raman crystal coating enhances the transmission of fundamental frequency light and Raman light;

[0062] OPO crystal coating is anti-reflective to fundamental frequency light, Raman light and parametric light (signal light and (or) idler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com