Deep ultraviolet light laser with tunable wavelength

A deep ultraviolet light and laser technology, applied in the field of optical waveguide theory, can solve the problems of large dispersion and transmission loss, small mode field overlap area, and high laser power density, so as to improve conversion efficiency, overcome group velocity mismatch, and reduce suppression. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in conjunction with the accompanying drawings.

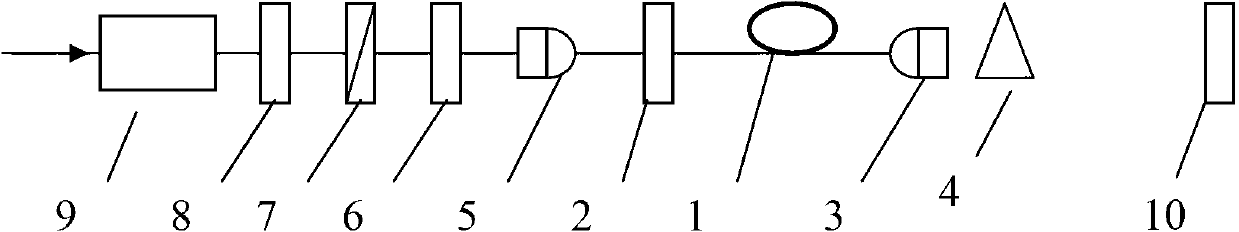

[0062] like figure 1 As shown, the wavelength tunable deep ultraviolet laser includes: highly nonlinear optical material 1, high reflection mirror 2, output beam collimator 3, beam splitter 4, pump optical coupler 5, dispersion compensation element 6, polarization A controller 7, a pump light power controller 8, an optical isolator 9 and a spectral filter lens 10.

[0063] The highly nonlinear optical material 1 is placed at the back end of the high reflective mirror 2, the output beam collimator 3 is placed at the output end of the highly nonlinear optical material 1, and the pump optical coupler 5 is placed close to the input end of the high reflective mirror 2 , the dispersion compensation element 6 is placed in front of the incident end of the pump optical coupler 5, the polarization controller 7 is placed in front of the incident end of the dispersion compensation elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com