Integrated railway signal machine

A railway signal machine and signal machine technology, applied in the direction of railway signals, visual signals, railway car body parts, etc., can solve the problems of many boxes and basic accessories, large floor space, and difficult maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

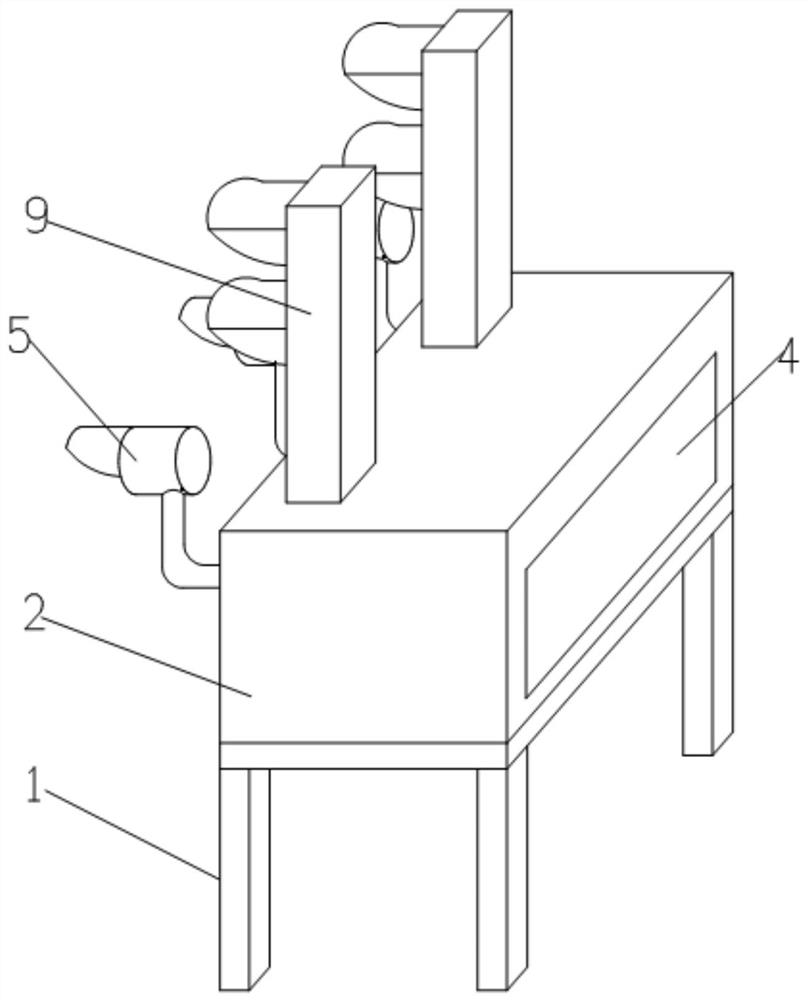

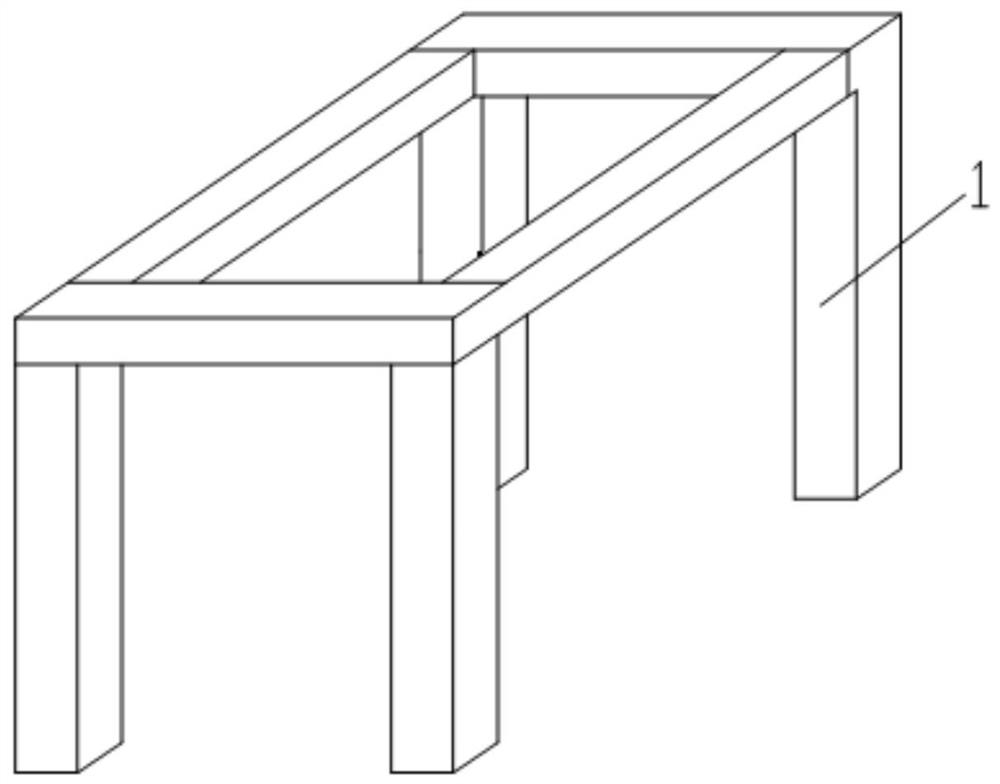

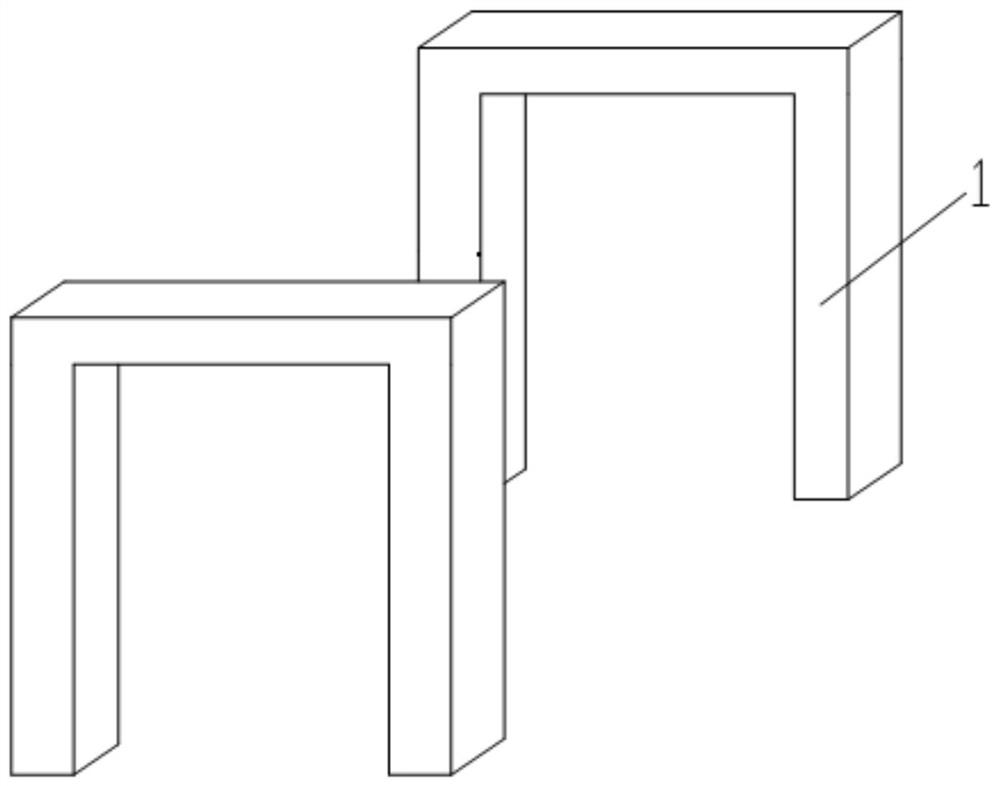

[0023] Example: see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , in the figure, 1-first foundation, 2-second foundation, 3-fixing bolt, 4-cover body, 5-departure indicator, 6-lighting transformer, 7-indicator installation hole, 8-terminal block, 9-Signal machine mechanism, 10-Cable entry hole (indicated position, but not limited to this position), 11-Signal machine mechanism lead hole; A-Signal machine, B-Junction box.

[0024] The integrated railway signal machine foundation includes the first foundation and the second foundation. The second foundation is detachably arranged on the first foundation through fixing bolts, and the second foundation is a hollow structure, and the second foundation area is provided with a cover. Departure indication The indicator is arranged on the front part of the second foundation through the installation hole of the indicator, and communicates with the inner cavity of the second foundation, the lighting transformer is arrang...

Embodiment 2

[0034] This embodiment is obtained by changing the technical features such as the structure of the first foundation 1 on the basis of the first embodiment, and the rest of the technical features are the same as the first embodiment, and the similarities will not be repeated here, wherein the detailed description of the technical features is changed It is: the first foundation 1 is a rectangular frame foundation (wherein, the rectangular frame foundation is two door-shaped frames or a rectangular overall frame, or other frames with stable support, and its material is iron, steel, aluminum alloy, glass steel, wood, Metal or non-metal materials such as composite materials).

[0035] By replacing the concrete foundation in Embodiment 1 with a rectangular frame foundation, the construction of the concrete foundation and the transportation of building materials are further reduced, which facilitates transportation, reduces the intensity of personnel, reduces the construction period o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com