Onion which have less pungent taste and does not form lachrymatory factor

一种洋葱、辛辣的技术,应用在洋葱及其制造领域,能够解决没有辛辣味等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

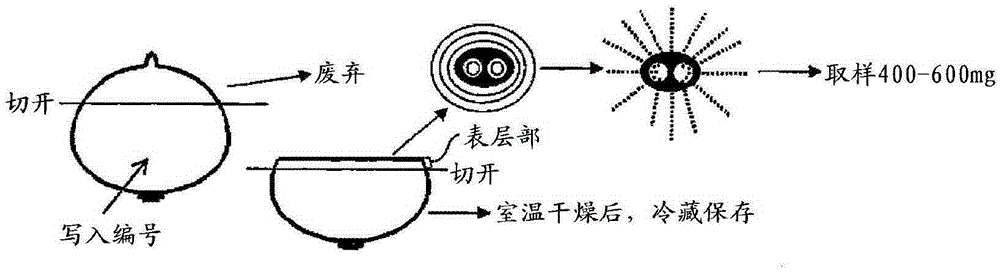

[0104] (Preparation of analytical samples)

[0105] In order to avoid differences in measured values or evaluations depending on the site used as the analysis sample, the following specific sites were used for the analysis sample. The analysis sample is taken as follows: at a height of 1 / 3 to 1 / 2 from the upper end of the onion ball, it is cut into 2 parts along a surface perpendicular to the vertical axis of the ball (the axis passing through the base part and the tip part of the onion ball) , from the scale leaves at the center of the cut surface of the upper part (including the tip part) or the lower part (including the bottom part) obtained (refer to figure 1 ). The "scale leaf at the center of the cut surface" refers to the innermost scale leaf (scale leaf surrounding the bud existing at the center of the axis) among the scale leaves appearing on the cut surface, or the surface layer of the scale leaf near the cut surface side . The "surface layer part" is, for examp...

Embodiment 1

[0128] Manufacture of spring-sowed onions without pungent and tear-jerking properties

[0129] (1-1) Production of M1 onion balls

[0130] A 10-cm-diameter plastic Petri dish to which about 1,500 seeds (6.08 g) of super-northern maple seeds were added was irradiated with a neon ion beam at 20 Gy to prepare irradiated first-generation (hereinafter referred to as M1) seeds. Get 60 grains from obtained M1 seed, carry out germination test, estimate germination rate and normal growth rate. Specifically, add the GoldenPeatban to the included plastic tray and fill it with 700mL of tap water. Absorb all the water after 10-15 minutes of water injection, and sow 60 seeds of the expanded Golden Peatban filled in the tray. Keep it as it is, and after leaving it indoors for one night, transfer it to a greenhouse (the greenhouse is set at 15° C.) to allow it to grow. One month after sowing, the germination rate was 86.7%, and the individual rate of the second leaf sheath was 55.8%.

[013...

Embodiment 2

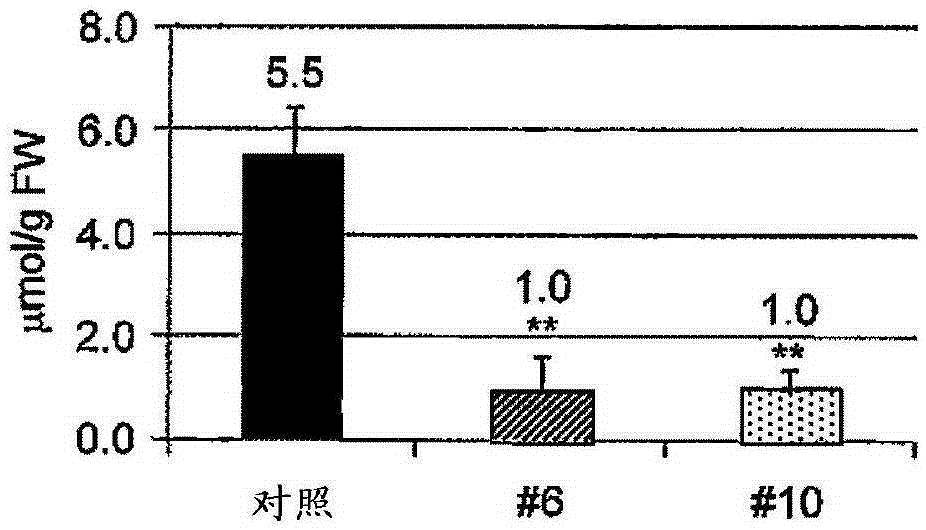

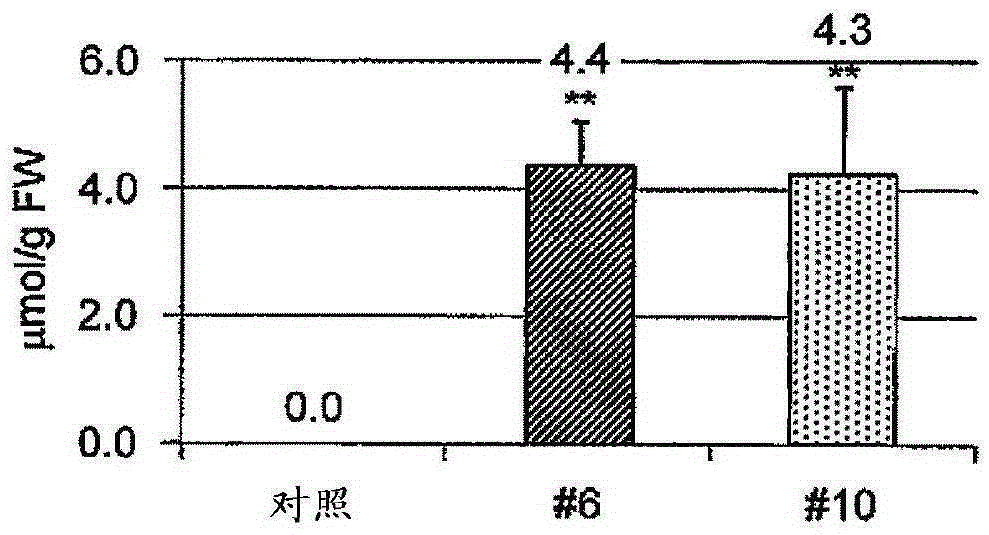

[0207] Various determinations

[0208] (2-1) Measurement of the amount of pyruvic acid produced when the tissue is broken

[0209] 600 mg of onion tissue collected by the method described in the above (1-4) "(Preparation of Analytical Sample)" was placed in a centrifuge tube (2 mL) manufactured by Eppendorf Tube Co. containing three 3 mmφ zirconium balls. 0.6 mL of distilled water was added, and it crushed by performing the process of 30 Hz x 2 minutes x 3 times using the MM300 bead mill manufactured by QIAGEN. After pulverization, it was allowed to stand at room temperature for 10 minutes, and then centrifuged at 15,000 rpm and 4° C. for 10 minutes to obtain a supernatant as a sample. 20 μL of the sample was added to a 96-well plate, 43 μL of water and 66 μl of DNPH solution were added 30 minutes after the pulverization started, and the reaction was carried out at 37° C. for 10 minutes. After 10 minutes, 66 μL of 1.5M NaOH was added to stop the reaction, and the mixture was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com